All-electric production systems solve potential problems

John Burdick, Robert Lopez

Cameron Subsea, Electric Subsea Systems

Increasing deepwater tieback distances can exceed the limits of conventional, electro-hydraulically controlled subsea systems. New technology addresses deficiencies of current subsea system controls technology, not only for these particular applications, but also for a broader set of challenges faced by operators.

All-electric subsea production systems have many advantages over their electro-hydraulic counterparts. Coaxial umbilicals are smaller, lighter, less complex, easier to manufacture, and more economical than hydraulic ones. In addition to increased reliability, greater flexibility and improved operability, coaxial umbilicals have the ability to increase stepout distance with minimal change to hardware at minimal cost. Health, safety, and environmental benefits are also realized.

Umbilical cost becomes a major factor as tieback distance increases. Depending on field configuration, an all-electric umbilical may cost between 40% and 60% of the material cost of a corresponding electrohydraulic umbilical. Add to this the savings realized by the exclusion of a high pressure unit, surface storage and flushing, subsea accumulation, and the hydraulic fluid itself, and the overall savings can be substantial even on moderate stepouts.

All-electric control and actuation systems overcome limitations inherent in electro-hydraulic systems in several areas, including:

1. Control fluid management - No hydraulic fluids to store, handle, transport, clean/flush, replenish or dispose. Also, electric controls eliminate large hydraulic power units (surface or subsea) and accumulators. These factors combine for environmental benefits plus simplified, less expensive, umbilicals.

2. Reliability - Increased system uptime with improved project profitability.

3. Response - Fast actuation response times with enhanced condition monitoring through high data transfer rates.

4. Flexibility - Adaptation to a wide range of configurations and applications.

Use of high pressure hydraulics to actuate subsea production controls is accepted offshore. However, as stepout distances increase, this becomes less attractive. Use of hydraulics requires large, complex umbilicals with high and low pressure hydraulic tubing, power conductors, communication lines, and chemical injection lines.

These umbilicals are not only expensive but difficult to handle as lengths increase.

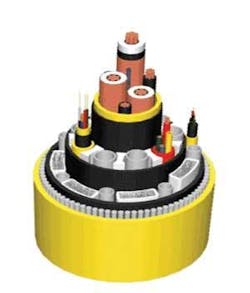

In contrast, using an all-electric alternative, particularly one using Direct Current (DC) power, reduces the umbilical to a coaxial cable which combines power and communication. The use of DC power allows transmission of communication superimposed on power over great distances using relatively small conductor sizing. When required, chemical injection tubing can be bundled into the umbilical.

With this alternative, the cost of umbilicals can decrease. Vessel costs required to handle and install smaller, less complex umbilicals also may be reduced.

Long-distance stepouts

As tieback distances lengthen, hydraulic tubing diameters must increase to overcome pressure losses. At extreme distances, additional pressurization may be necessary.

Likewise, copper conductors within the umbilical must be oversized to compensate for voltage drops in order to provide sufficient power for subsea control equipment such as processors and sensors.

Standard communication protocols of shielded, twisted pair wires become impossible, making fiber-optic communication the only alternative. This requires additional tubing to house and protect the fibers, and adds complexity to an umbilical.

If stepout distance is greater than the maximum continuous length of umbilical that can be made or handled, one or more splices will be required. Splices are difficult, costly, and carry high failure potential.

Breaking out these complex umbilicals at both the surface and subsea end is complicated by the mix of high and low pressure hydraulics, high voltage/current wiring, fiber optic communication lines, and chemical injection lines. Each line must be isolated from the others and terminated or spliced within an enclosure.

Weight of these large umbilicals requires special consideration whenever the platform necessitates dynamic hang-offs.

Eliminating hydraulic tubing, three-phase power conductors, and separate communication lines reduces the umbilical configuration to the required number of coaxial lines. Power conductor sizing doesn’t change significantly with increased umbilical length because of the small line loss characteristic of DC power transmission.

In contrast, Alternating Current (AC) losses increase rapidly with transmission length because of impedances caused by resistance, inductance, and capacitance. So, conductor size must increase to overcome voltage drop across the umbilical, or else transmission voltage must be high.

DC is subject only to simple line resistance, easily overcome by raising the transmission voltage slightly to overcome the voltage drop. This allows conductor sizing to be reduced. Also, only one conductor is required to transmit DC. Three-phase AC requires three conductors.

Transmission of DC voltage on coaxial cable allows communication data to be superimposed on the power, yielding bandwidth sufficient for control signals and sensor data to transmit a distance of 200 mi. Beyond that, the coaxial center conductor can be produced with a tubular cross section housing fiber optic communication lines. This doubles the possible transmission distance without repeaters. Using repeaters on the fiber optic communication line permits virtually unlimited stepout distances.

Using “comms on power”, or fiber in the core, eliminates the need for separate twisted pair copper or fiber optic communication lines, further reducing the size, weight, complexity, and cost of the umbilical.

Smaller diameter umbilicals typically allow a tighter bend radius, which may improve routing on the platform and on subsea distribution equipment. Decreased bend radius also allows the operator to use smaller diameter spools which are easier to store and handle. The reduced outside diameter of the umbilical means a longer continuous length can be contained on a spool.

HSE advantage

A further advantage of all-electric actuation is in the health, safety, and environmental areas.

Elimination of hydraulic fluid and the equipment necessary to store, pump, pressurize, filter, and dispose of it can be a benefit. Health issues with hydraulic fluid include skin contact, slipping on leaks, and spills. Safety is compromised with high pressure accumulator bottles, and pressurized hoses and lines. Environmental issues include leaks and venting of hydraulic fluid into the sea.

These are alleviated with all-electric valve actuation and control systems.

Hydraulic fluid is intended to be contained at all times. However, pump and valve seals wear out and leak, pipe and tubing fittings loosen with time and vibration, and drums get knocked over, punctured, and dropped. Although hydraulic fluid may not be a toxic substance (though the addition of biocides may yield toxicity), direct contact with any industrial chemical compound is best avoided.

Hydraulic fluid can irritate skin, enter the mouth if hands are not clean, and can cause severe discomfort if introduced into the eyes. Long-term health effects of hydraulic control fluids are uncertain, but that is not an issue, of course, if such fluids are not present.

Safety concerns of hydraulics are immediate and tangible. A small amount of hydraulic oil on the deck can cause a slip and the resulting fall can be devastating. Slips, trips, and falls are the number one source of disabling injuries in the workplace. Oily residue from leaks, spills, or routine maintenance increases the probability of falls. Turning wrenches with oily hands can result in ‘busted knuckles’, and the reduced gripping strength resulting from working in an oily environment can cause a hammer to become a projectile.

The greatest safety concern of hydraulics is the extremely high pressure equipment used. Pumps, lines, fittings, hoses, and accumulators are designed to withstand the high pressures and forces, but failures do occur. The results can be catastrophic. Lives have been lost working on ‘depressurized’ accumulator bottles and injuries have occurred from flying debris following pressure containment equipment failure.

Environmental issues are under increasing scrutiny. Many geographical areas embrace a zero discharge policy and heavily penalize offenders. Mandatory rig and platform shutdowns by governing authorities on the basis of fugitive emissions evidence has increased substantially. Millions of dollars in lost revenue are at risk while an operator attempts to find and resolve a small hydraulic leak.

Closed loop systems eliminate the need to vent hydraulic fluid into the sea but introduce a new set of challenges by requiring subsea reservoirs or return paths to the surface. These options introduce additional potential leak points and add complexity to the system.

Even with closed loop hydraulics and no leaks, fluids can become contaminated over time and must be disposed of or additionally refined for reuse. This can result in operational expenses for replacement fluid, downtime, transport of contaminated fluid to a suitable facility, and processing costs. It is also a labor and equipment intensive process which raises the potential for spills and accidents.

An all-electric controls system also saves space. Replacing the HPU, reservoirs, surface accumulators, and all the related piping with an all-electric power and control cabinet, roughly the size of a filing cabinet, opens up hundreds of square feet of deck space. Additionally, storage space normally used for hydraulic fluid drum storage can be freed.