CPC says fixing equipment at two mooring points will take a month each

Offshore staff

Oil exports via the two SPMs have been suspended due to equipment damaged by bad winter weather, CPC said Aug. 22, confirming a Reuters report on Saturday.

The CPC’s Marine Terminal has had SPM-1 and SPM-2 in operation since 2002 and 2014, respectively.

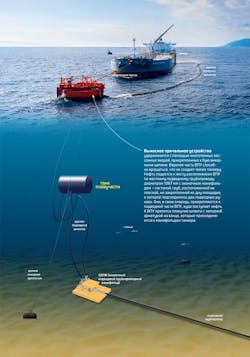

An oil loading system consists of subsea and sea surface equipment, including a subsea pipeline, a pipeline end manifold, suction anchors, anchor chains, subsea hoses and SPM.

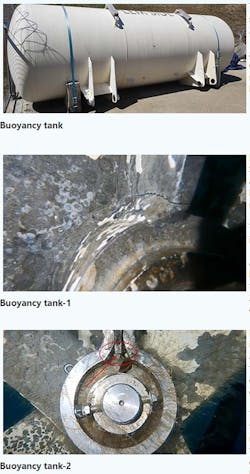

While performing scheduled maintenance this month on SPM-1 and SPM-2, divers discovered cracks in subsea hose attachments to buoyancy tanks (a buoyancy tank is a hollow air-filled vessel designed to keep subsea hoses in a necessary configuration).

There is no threat to the flora and fauna of the Black Sea, CPC said, and the integrity of the equipment remains intact.

Due to the damage discovered on subsea equipment, CPC immediately contacted the SPM manufacturer, IMODCO, and an organization that supervises safe operation of equipment, the ABS classification society, for consultations whether the equipment could continue to be operated, providing comprehensive information about the defects found.

These entities strongly recommended that the operation of the SPMs should be suspended until the buoyancy tanks were replaced. The ABS classification society, in particular, stressed that exceptionally adverse weather conditions had been observed during the 2021-2022 winter season, which could have caused the damage that was discovered. As a reminder, it was the abnormal storms that caused the damage to some sections of floating hoses in March of this year.

The shareholders of the company were notified about the defects on the buoyancy tanks 1 and two on Aug. 5 and 17, respectively.

The CPC Marine Terminal is temporarily loading crude oil by using only SPM-3.

The use of the single SPM will allow to meet shipper nominations with reduced volumes.

CPC takes an uncompromising position on environmental protection and industrial safety while operating its Marine Terminal in the Black Sea as well as prevention of oil spills.

CPC stated, "We consider it necessary to stress that the above-mentioned damage did [not] lead to any incident or accident associated with oil spill. There is no threat to the public or the environment. The company has taken action to prevent any such risks on the equipment."

CPC has developed a corresponding task order and intends to replace the tanks with new ones from inventory. A prequalification selection of bidders for the job is in progress.

CPC is going to advise how the situation develops at a later date.

On Aug. 23, Reuters reported the following summary:

- Two of three single mooring points need repairs;

- CPC still looking for firm to carry out the work;

- August and September export schedules will have to be revised;

- Tengizchevroil unaffected as Tengiz Field undergoing maintenance; and

- Main export route for Kazakh crude.

08.23.2022