Increased demand for AUVs drives innovation, adaption

A staff report

Operators are increasingly looking to autonomous under water vehicles to meet their subsea inspection and survey needs as they move into ultra-deep water and remote locations. For the past two years, asset owners and producers have expressed a strong demand for technologies that can help them reduce their dependence on platforms and support vessels, while improving remote control capabilities and reducing emissions.

In response, manufacturers and service companies have developed the next generation of AUVs that offer increased autonomy, advanced sensors, and can reside subsea. Recent technological innovations have pushed AUV systems toward longer endurance, greater depth capabilities, rapid response capabilities, 3D mapping services and even limited intervention capabilities.

Subsea residency is increasingly the goal for newly introduced AUVs, and subsea docking systems are a vital part of that technology development. Recently, in what was reported to be a world’s first, Modus Seabed Intervention completed the autonomous docking of a hybrid autonomous underwater vehicle (HAUV) to an Equinor subsea docking station (SDS). This is part of an Equinor-funded test scope in northeast England. The HAUV system, based on a Saab Sabertooth AUV, successfully docked to the SDS without any operator intervention.

The entire operation was monitored live from the Modus Command and Control Centre at its headquarters in Darlington, using a secure data network and free space optics at the test site.

Some of the same vendors and manufacturers are working together to provide new power options, to enhance subsea residency. Ocean Power Technologies Inc. (OPT), Modus, and Saab Seaeye have been working together to develop a solution for carbon-free subsea AUV residency. This system is designed for autonomous offshore operations, with the OPT PowerBuoy power and communications platform at its core. Via an integrated mooring and subsea power/data transmission cable, a PowerBuoy can provide carbon-free power to a seabed docking station to recharge an AUV, while enabling secure data transmission to and from shore-based operations anywhere in the world.

The involved companies note that increasing the length and variety of missions an AUV can undertake can lower costs and risks, and true autonomous control with access to data in real time is a key goal for offshore operators. An autonomously powered interactive docking station independent of traditional infrastructure offers efficiency in routine operations and facilitates timely response to ad hoc events (extreme weather, subsea equipment failure) more rapidly than possible with surface-based vessels.

Freedom is supported by a docking station at the seabed. The vehicle has hybrid functionality that enables it to operate in two modes: remotely piloted, via tether or through-water communications, to provide real-time control, or autonomous mode, which relies on advanced autonomy to complete mission scopes. In September 2020, Oceaneering successfully docked the Freedom vehicle with Equinor and Blue Logic’s Underwater Intervention Drone (UID) Docking Station at its testing facility. The vehicle launched from the quayside and landed while in autonomous mode using a tether only for Wi-Fi feedback.

Another hybrid AUV/ROV, the Aquanaut, has been developed by Houston Mechatronics Inc. (HMI). Described as an all-electric subsea robotic transformer, the Aquanaut can transform from an AUV into an ROV in less than 30 seconds, according to HMI President and CEO Nic Radford. The tetherless subsea vehicle has a working range of 200 km (124 mi), 3,000 m (9,842 ft) depth rating, and 24-hour endurance period. In 2020, HMI entered a collaboration agreement with Stinger Technology AS. The company will provide the AUV/ROV and necessary services needed to target and execute IRM operations within the Norwegian oil and gas market. This year Aquanaut will be in Norway finalizing product qualifications in order to be ready for commercial applications in 2022.

Elsewhere, Saipem says it has begun sea trials of its FlatFish AUV, a resident subsea autonomous vehicle that uses AI to perform complex inspection tasks. Since March 2018, Shell has been working with Saipem to develop the FlatFish technology and qualify it for commercial application. Saipem will reportedly further enhance its FlatFish features with capabilities for riser inspection, data harvesting from subsea sensors, and contactless monitoring of the cathodic protection systems. The company is also working on a flying-hanging garage for the launching/recovering and subsea recharging/reprogramming of the FlatFish from offshore platforms.

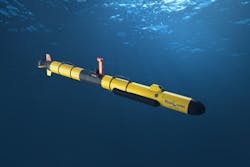

Manufacturers are also looking to extend operational duration and offer extended mission timeframes. Recently, Kongsberg Maritime launched the next generation of its HUGIN Endurance, which is said to increase operational duration to about 15 days, enabling extended survey and inspection missions far from shore. This longevity allows the new AUV to undertake extensive missions without the support of a mothership. It is capable of mission ranges up to 2,200 km (1,367 mi), according to the company.

AUVs are also being designed to gather seafloor and geoscience data. Last year, Blue Ocean Seismic Services (BOSS) completed sea trials of a test prototype version of its autonomous underwater vehicle offshore Australia. During the trials, the testbed ocean bottom seismic robotic vehicle traversed a series of waypoints, while simultaneously providing status updates to a master vessel. It also logged flight and engineering data which is being used for further systems development. The trials also reportedly validated BOSS’s electronics and software system, confirming its efficacy underwater. Collected data collected will support the design and development of the final product ahead of commercialization.

Development of the BOSS AUV is supported by bp Ventures, Woodside Energy and Blue Ocean Monitoring, as a potentially lower-cost, faster, safer, and less carbon-intensive approach to OBS acquisition. Following further work, Blue Ocean plans to stage further seismic trials at multiple locations, followed by pre-commercial sea tests starting in the first half of 2022.

Blue Ocean claims use of its vehicles could cut seismic survey costs by more than 50% and reduce the need for energy-intensive exploration vessels. The systems are powered by rechargeable batteries, so the nodes can remain submerged for almost three months, transferring to different locations underwater before recharging and redeployments.

Another recent offering is the SPICE AUV, an acronym that stands for Subsea Precise Inspector with Close Eyes. Developed by Kawasaki Heavy Industries, SPICE is said to be the world’s first AUV equipped with a robot arm for performing subsea pipeline inspections. An inspection tool unit is fitted with close-range sensors at the end of the robot arm. SPICE controls the robot arm autonomously to track the pipeline and perform inspection operations. The AUV is designed for intelligent and low-logistic pipeline and subsea asset inspection operations in waters down to 3,000 m (9,842 ft). To support accurate and long-duration navigation on its missions, the vehicle is fitted with Sonardyne’s hybrid navigator SPRINT-Nav system. In addition, it is operated using a Kawasaki-developed docking station, which increases inspection operation efficiency and reduces cost requirements. Recently, Modus acquired two SPICE AUV systems, which it says will enhance its ability to offer high-quality, low-cost integrated services.

Other vendors are also collaborating to meet the industry’s demands for advanced AUV technology. Recently, Ocean Floor Geophysics (OFG) and DOF Subsea (DOF) announced plans to further develop OFG’s AUV non-contact integrated Cathodic Protection (iCP) inspection system, with pooling of resources on various pipeline inspection and geohazard surveys. They also plan a coordinated response to increased demand for AUV surveys.

OFG’s iCP technology for AUV pipeline and infrastructure checks is said to allow anomalies and the overall system health status to be analyzed in near real-time offshore. The miniaturized electronics are also said to simplify integration and deployment on light logistics AUVs, ROVs and shallow water active towfish for pipeline, cable, structure, and umbilical inspection.