Wild Well adds Fugro BOP technology to subsea capping stacks

Offshore staff

HOUSTON – Wild Well Control Inc., a Superior Energy Services company has contracted Fugro to provide BOP intervention skids and test units for inclusion in its subsea response kit.

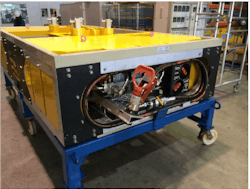

As part of the WellCONTAINED subsea capping stack program, Fugro’s new 450/150 Mark 3 BOP intervention skids will improve both pumping capability and water depth rating and will replace the existing equipment in inventory, according to Wild Well.

Doug Graham, Fugro’s ROV services and tooling global director, said the company’s latest generation BOP technology delivers a full skid testing without the requirement of an ROV, the ability to interface to most work-class ROV systems, and a bespoke designed self-contained storage and maintenance transport container.

Graham added: “Deployments of the skid system to date have included full functional testing on a Fugro ROV at 3,800 m [12,467 ft] water depth. The BOP system is depth rated to 4,000 m [13,123 ft].”

Chris LeCompte, Wild Well’s general manager of WellCONTAINED, said: “This new equipment supports our initiative to provide a comprehensive subsea capping and containment program for operators worldwide. We are excited that this field proven equipment enhances our kit while also supporting the increased 3,800-m depth rating of our capping stack equipment.”

The WellCONTAINED inventory is staged in a ready-to-deploy state in both Aberdeen and Singapore. The equipment at each location includes full subsea well intervention systems, including a subsea capping stack, debris removal shears, hardware kits for the subsea application of dispersant and inhibition fluids, and other ancillary equipment.

07/18/2019