Shipping industry actively moving toward alternative fuels

By Nathan D. Wood, Dr Robert Moorcroft and Dr Torill Bigg, Tunley Engineering

The shipping industry is estimated to be the source of 13% of the worlds SOx emissions. A key issue with SOx is its existence as PM2.5, which are particles small enough to pass through the lungs into the bloodstream contributing to myriad health conditions. SOx emissions can be so mitigated by using low-sulfur fuel oil; however, this comes at an increased financial cost.

An increasing number of regulations and targets are being implemented to reduce the greenhouse-gas (GHG) emissions produced by shipping. The International Maritime Organization has set stringent targets to reduce the carbon footprint of international shipping by at least 40% by 2030, compared to 2008 levels. Whilst the 2021 EU Green Deal sets in place targets for a 90% reduction in port city GHG emissions by 2050. Furthermore, the EU has publicly declared the need to bring shipping under its Emissions Trading System, which sets caps on the emissions of companies per annum, with financial implications for companies that breach this limit.

Alternative fuels

To meet regulations and reduce carbon footprint, the shipping industry is actively moving toward alternative fuels.

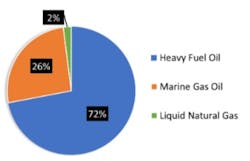

Both LNG and hydrogen are gaining traction as fuels for the future. However, questions arise from these choices surrounding sustainability and reliance on finite fossil fuels. Currently, LNG makes up about 2% of fuel use in the shipping industry, and it has the advantage of reducing PM by more than 95%, NOx by over 80% and SOx by more than 90% compared to heavy fuel oil.

A key issue with LNG ships is “methane slip,” the escape of unburned methane from marine engines. Methane is a far more potent GHG than CO2. Findings by the European Transport and Environment department indicate that LNG may not reduce GHG, or only marginally so when making favorable assumptions on methane slip.

The combustion of hydrogen is a cleaner process when compared to fossil fuels, producing only water as a byproduct. However, due to the higher temperatures present within hydrogen engines, the production of NOx can be higher than hydrocarbon fuels. However, NOx emissions can be mitigated by implementing current technologies such as exhaust gas recirculation and catalytic converters. One key issue is that the production of hydrogen is heavily reliant on hydrocarbon feedstocks, as 96% of all hydrogen is currently produced by reforming fossil fuels. Methods exist to produce hydrogen from renewable electricity without the use of fossil fuels, such as water, alkaline and membrane-less electrolysis. However, this currently remains economically unviable compared reforming fossil fuels.

There is also great discussion on methanol as a potential fuel for shipping. Methanol produces no SOx and much lower PM/NOx compared to heavy fuel oil. A key advantage of methanol is its comparable energy density (15.8 MJ/L) to LNG (20.8 MJ/L).

Methanol has also been successfully trialed as a marine fuel. One advantage of methanol is that it can be sourced from biomass (e.g., waste products of agricultural activity). However, most of the current world supply of methanol relies on the production from fossil fuel feedstocks.

Reducing the emissions from ships while at port can also significantly reduce the environmental impact of shipping and improve the air quality at port towns and cities through decreasing PM, NOx and SOx emissions.

Carbon emissions whilst docked are approximately 1.58 CO2e kg per deadweight tonnage (DWT - the sum of all cargo, ballast, freshwater, provisions, passengers, and crew). This can be reduced to effectively 0.00 kgCO2e/DWT when using a ship-to-shore electricity supply generated from renewable sources instead of auxiliary steam boilers.

Numerous ports across the world are also now trailing low and zero-emission technologies and fuels. A great example is the Port of Vancouver, where numerous sustainable initiatives are being tested. These include biodiesel fuels for boats, ferries and locomotives, hydrogen-powered equipment and battery-electric powered terminal tractors.

About the authors:

Nathan Wood is a carbon reduction scientist at Tunley Engineering and is responsible for processing, analyzing and presenting carbon assessment data.

As a carbon reduction scientist, Dr. Robert Moorcroft applies his multidisciplinary scientific background spanning biology, chemistry and materials science to the carbon assessments and realistic reduction plans for the customers’ often complex needs.

Dr. Torill Bigg is the chief carbon reduction engineer of Tunley Engineering and leads the carbon reduction team. Torill is passionate about environmental protection and decarbonization.

01.25.2023