As construction of the first multi-purpose floater hull in the Fast4Ward program (FPSO Liza Unity) nears completion at the SWS shipyard in Shanghai, China, SBM Offshore has ordered two more. The company has signed contracts with Shanghai Waigaoqiao Shipbuilding and Offshore Co. (SWS) and China Merchants Industry Holdings for construction of its fourth and fifth Fast4Ward hulls.

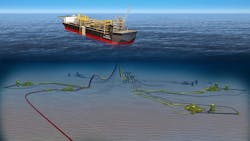

The Fast4Ward program features a newbuild, multi-purpose hull with several standardized topsides modules.

In addition, the company has signed contracts with Petrobras for the 22.5-year lease and operation of the FPSO Sepetiba (formerly known as Mero 2). The newbuild vessel, which will incorporate the Fast4Ward program, will be deployed at the Mero field in the Libra block in the presalt Santos basin, 180 km (112 mi) offshore Rio de Janeiro. Delivery is scheduled for 2022.

Petrobras operates Libra in partnership with Shell, Total, CNODC and CNOOC. Brazil’s state-owned company Pré-Sal Petróleo manages the production-sharing contract.

Finally, Esso Exploration and Production Guyana Ltd. (EEPGL) has contracted SBM to perform front-end engineering and design (FEED) for an FPSO for the Payara development project in the Stabroek block offshore Guyana.

ExxonMobil subsidiary EEPGL is the operator of the Stabroek block with partners Hess Guyana Exploration Ltd. and CNOOC Petroleum Guyana Ltd.

Prior to necessary government approvals and project sanction, the contract award will initiate a limited release of funds to begin FEED activities and secure a Fast4Ward hull.

Following FEED and subject to government approvals in Guyana, project sanction and an authorization to proceed with the next phase, SBM will construct, install and then lease and operate the FPSO for a period of up to two years, after which the vessel ownership and operation will transfer to EEPGL.

The FPSO, to be named Prosperity, will use a design that largely replicates the design of the FPSO Liza Unity.

The FPSO will be designed to produce 220,000 b/d of oil, will have associated gas treatment capacity of 400 MMcf/d and water injection capacity of 250,000 b/d. It will be spread moored in water depth of about 1,900 m (6,234 ft) and will be able to store around 2 MMbbl of crude oil.

The company said it is exploring options to maximize local content and Guyanese workforce development, building on efforts to date on the FPSOs Liza Destiny and Liza Unity.

MODEC to deliver Barossa FPSO

ConocoPhillips Australia has contracted MODEC Inc. to supply an FPSO for the Barossa gas field offshore Australia.

In June 2018, MODEC was awarded a front-end engineering design (FEED) contract. It has now been selected as the turnkey contractor based upon its successful performance and deliverables of the FEED contract.

The Barossa FPSO is intended to produce gas and condensate from subsea wells and after treatment, supply feed gas to the Darwin LNG plant via a gas export pipeline.

According to MODEC, this is its largest size of “Gas FPSO” to date, which will be able to export more than 600 MMscf/d of gas as well as store up to 650,000 bbl of condensate for export. It has been designed to withstand a 100-year cyclone event at a water depth of 260 m (853 ft) and located some 300 km (186 mi) north of Darwin.

The company will be responsible for the engineering, procurement, construction, and installation of the FPSO, including topsides processing equipment as well as hull and marine systems. Scheduled for delivery during 2023, the FPSO will be permanently moored by an internal turret mooring system supplied by a MODEC group company, SOFEC Inc.

The Barossa FPSO will be the first application of MODEC’s M350 Hull, a next generation newbuild hull for FPSOs. The full double hull design has been developed to accommodate larger topsides and larger storage capacity than conventional VLCC tankers, with a longer design service life of 25 years and beyond. The hull will be built by Dalian Shipbuilding Industry Co. Ltd. in Dalian, China.

The FPSO features a boiler and steam turbine-based power generation system instead of conventional gas turbines, which is said to help reduce the carbon dioxide footprint of the facility.

The Barossa FPSO will be MODEC’s sixth FPSO in Australia.

The final investment decision for the Barossa project is expected in early 2020.

The Barossa joint venture is currently formed by ConocoPhillips Australia Barossa Pty Ltd. (field operator, 37.5%), SK E&S Australia Pty Ltd. (37.5%) and Santos Offshore Pty Ltd. (25.0%).

In October 2019, Santos agreed to buy ConocoPhillips’ northern Australia business for $1.39 billion. •

About the Author

Jessica Stump

Editor

Jessica Stump is editor of Offshore Magazine. She uploads and writes news to the website, assembles surveys and electronic newsletters, and writes and edits articles for the magazine. She was the summer editorial intern at Offshore in 2009 and 2010 before joining full time in April 2011. She has a journalism degree from Texas Tech University.