Maersk Drilling converting North Sea jackup for lower-emissions operations

Maersk Drilling is converting the harsh-environment jackup Maersk Intrepid for ‘cleaner’ and more efficient drilling operations. The rig, currently contracted to work for Equinor until August 2020 on the Martin Linge project in the North Sea, will soon become the first ‘hybrid’ low-emission rig in the contractor’s fleet. The upgrades include installation of a new battery-based hybrid power solution that makes more efficient use of the engines, thereby lowering carbon dioxide (CO2) emissions; selective catalytic reduction (SCR) systems that minimize nitrogen oxide (NOx) and soot emissions; Energy Emission Efficiency software that monitors and optimizes all energy use onboard; and implementation of the NOVOS drilling system to help the drill floor team execute processes more consistently, with interfaces to third-party algorithms to further improve drilling performance.

Norway’s NOx Fund, an industry scheme dedicated to cutting NOx emissions on the Norwegian continental shelf, is funding up to 80% of the upgrade costs, and Equinor is providing further support via its compensation format arrangement for emission-reducing measures. Assuming a successful outcome to the project, Maersk Drilling will seek to extend the upgrades to other rigs in its fleet.

The Maersk Intrepid, a CJ70 XLE design jackup that entered service in 2014, is equipped for year-round harsh environment operations.

Offshore spoke to the rig’s Technical Superintendent, Mikkel Sondergaard Pedersen, and to Maersk Drilling’s Chief Technical Officer, Frederik Smidth, and Senior Mechanical Engineer Jan Hoffner, about the background to the conversion and the progress achieved to date.

Offshore: Is the Martin Linge development Equinor’s first acquaintance working with the Maersk Intrepid?

Pedersen: The rig had worked previously for Equinor on the Sleipner field in the North Sea, and its first ever job was in fact on Martin Linge back in 2014, when the field’s operator was Total. The current upgrade program has led to further enquiries from Equinor regarding energy efficiency and we have an ongoing dialogue on further initiatives.

Offshore: Was Equinor’s desire to comply with future Norwegian emission reduction targets one of the main drivers?

Smidth: Maersk Drilling had been working for some time on development of energy emission efficiency solutions for various rigs. When we saw the opportunity to help Equinor, as our client, achieve its carbon reduction targets, we approached them with the solutions now being implemented on Maersk Intrepid.

Offshore: Are there certain characteristics of this rig, or the CJ70 design in general, that facilitate the planned upgrades?

Hoffner: All electrical motors above a certain size have been equipped with variable-frequency drives (VFDs) to control the output of the motor to the required demand. Motors for the topside drilling equipment are also controlled via VFDs. This means the reverse power generated when the motor has to stop a load, with the implemented upgrades, can be stored in the energy storage system. It should also be noted that Maersk Drilling’s CJ70 designs are specially equipped and prepared for these kinds of upgrades.

Offshore: When the company first made the announcement of this program in May, it hoped to complete the emissions-related upgrade in July, for the hybrid batteries. What has been the reason for the delay?

Pedersen: Extensive simulations have been performed, in co-operation with Aalborg University in western Denmark, to ensure the correct capacity of the battery bank. In addition, a completely new design of a turnkey container solution had to be developed with a supplier to obtain the most optimal solution for the CJ70 XLE rigs. As Maersk Intrepid will likely also be in accommodation mode in 2020, we have decided to install the batteries next spring. The installation of the selective catalyzer reduction (SCR) units is already under way.

Offshore: Are the SCR systems a new development?

Hoffner: Maersk Drilling installed an identical solution on Maersk Innovator in 2014, so from our point of view, this is proven technology. The selected system is particularly well suited to the dynamic load patterns encountered in offshore operations, combined with a patented high efficiency urea injection system.

Offshore: What level of emissions do you expect to achieve compared to the rig’s existing output?

Smidth: The simulations of the power grid on a CJ70 XLE rig indicate an estimated fuel saving in double-digit percentage figures compared to the current average operational consumption on a CJ70 – with, of course, a corresponding reduction in CO2 emissions. With the SCR units we expect a minimum 90% reduction in NOx emissions.

Offshore: In terms of energy use, can you provide scenarios of how the hybrid power approach might work, depending on the drilling task?

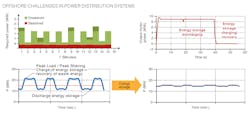

Hoffner: The peak-shaving capability introduced by the hybrid power energy storage system (ESS) will result in a reduced number of engines running during tripping in/out operations while running the drawworks in Multi Machine Control (MMC auto function), manual operation or other high power consumption activities on topside.

Implementation of the ESS adds energy to the grid, leveling out power peaks to obtain a constant load on a reduced number of engines. This results in a higher average load on the engines at a more optimal point on the Specific Fuel Oil Consumption Curve, which also leads to enhanced engine performance. Furthermore, waste energy recovered from electrical braking of the drawworks can be used to charge the ESS. In the current rig layout this energy is not being used and is therefore disposed of in the water-cooled brake resistors as heat.

In general, the installation of the ESS on the rigs topside provides attractive possibilities to operate the rig in an ever-more responsible and cost-saving way when operating heavy machinery on the drill floor.

Offshore: Are Maersk/Equinor already looking ahead to further refinements to reduce energy use/emissions?

Pedersen: Yes, we are looking at other solutions that will contribute to a further reduction in CO2 and NOx emissions. For example, Maersk Drilling has initiated an internal campaign that encourages all employees to submit suggestions for potential fuel savings. The next CJ70 is in the pipeline for a similar upgrade and we are also considering these solutions for semis and drillships. Our drillships have been designed with energy storage in mind, so they could be equipped with these new measures with only minor rig modifications. We are seeing more and more focus from our clients for these kinds of solutions and we are assessing the possibilities for some of our long-term drilling program proposals.

Offshore: What is the background to the cloud-based Energy Emission Efficiency software?

Smidth: This tool was developed in-house at Maersk Drilling with a big data approach, with Maersk Integrator used for the first pilot in 2016 when the rig was working for Equinor. The Energy Emission Efficiency software visualizes how and where energy is consumed on the entire rig, and this allows the operator to focus on unnecessary power consumption. To an extent it has changed the mindset of the personnel running the power plant on a rig, leading to substantial fuel savings. Following the upgrades to Maersk Intrepid, there will be a continuous focus offshore on the rig’s fuel consumption.

Offshore: Finally, can you supply how the NOVOS drilling system works and the benefits to Martin Linge or other projects?

Pedersen: NOVOS manages safe operation of rig equipment through automated processed while allowing external parties to optimize performance within the process. NOVOS offers a software developer kit that allows personalized applications to be created. Hence operators, contractors or service companies can apply optimization with their own applications while maintaining the proven safety and precision of NOV control systems. •

About the Author

Jeremy Beckman

Editor, Europe

Jeremy Beckman has been Editor Europe, Offshore since 1992. Prior to joining Offshore he was a freelance journalist for eight years, working for a variety of electronics, computing and scientific journals in the UK. He regularly writes news columns on trends and events both in the NW Europe offshore region and globally. He also writes features on developments and technology in exploration and production.