OTC 2023: HexDefence improves scour protection around offshore wind monopiles

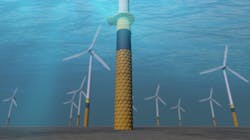

HOUSTON — Balmoral has developed a composite system designed to reduce scour phenomena around fixed wind turbines.

These can lead to seabed erosion and impact foundation strength and stiffness, potentially causing foundation instability, inter-array cable damage and ultimately cable failure.

Scour protection, used to defend the seabed around a monopile structure, typically involves the application of a layer of material around the base of the monopile to prevent sediment erosion. This can comprise various materials such as rock, concrete or a specially designed geotextile fabric.

The layer is placed on the seabed around the monopile to dissipate the energy of the fluid flow and reduce erosion rates.

However, the process involves careful monitoring to avoid damage to the turbine, seabed and associated cabling, and the associated costs and carbon footprint (due to the extra quarrying and vessel time for installation) can be substantial.

Balmoral HexDefence’s scour protection system, which is made from lightweight composites, integrates seabed protection and flow reduction, and it is designed to minimize offshore operational costs and potential cable failure.

It is said to eliminate the requirement to dump rock, providing a non-invasive approach to protecting the monopile and the immediate area, and is straightforward to install, the company said.

And the system can be used with anti-fouling coatings and does not require special equipment for end-of-life recovery.

Fraser Milne, engineering and projects director, said, “The interlocking panels are generally 10 m long and custom-sized to fit varying monopile diameters and feature integrated lifting and access points.

“In simple terms, the installation process involves sinking the foundation, sleeving it with HexDefence, fitting the transition piece and assembling the pylon and blades. The system is also suitable for retrofitting to existing monopile structures.

Preliminary work on the design was based on existing VIV suppression products used by the oil and gas sector. Final prototype testing took place at a national hydrodynamic laboratory.

“We believe the system can save wind farm developers around 70% in installation costs when compared to traditional rock dumping methods,” Milne added.

Balmoral is at OTC booth 1739.

05.01.2023