Performance of acid-fracturing treatments in low-pressure, low-temperature wells

B.K. Dutta

M. Yaseen

Bapco

E. Chacon

T. Kritzler

Halliburton Energy Services Inc.

The main objective of a stimulation treat-ment is to increase the rate at which the formation delivers hydrocarbons natur-ally. Fracturing treatments are defined as treatments in which the injection rate of the fluid is larger than the fluid leakoff into the matrix of the formation. The pressure in the wellbore will therefore buildup and eventually lead to tensile failure of the rock, creating a conductive channel. Because of the reactive nature of the fluid, the addition of acid in treatments for carbonate formations can create a conductive channel. The aim is to change the future flow pattern of the reservoir from radial to linear to effectively stimulate the reservoir and increase production.

The first hydraulic fracturing treatment was performed in 1949. Since that time, hydraulic fracturing has increased recoverable reserves more than any other technique. Although many formations in North America are sandstone and require the use of granular propping agents, acid fracturing is more commonly used in Europe and the Middle East, especially in Bahrain and Saudi Arabia.

The Bahrain oil field

The Bahrain field, discovered in 1932, is an asymmetrical anticline trending in a north/south direction. The sedimentary column extends from Cambrian Saq sandstone to the Miocene Reefal deposits exposed on the surface. The field contains 22 reservoirs with hydrocarbon content varying from tarry oil in Aruma to dry gas in Khuff reservoirs. The zones of interest are the limestone Aa and Ab. These two layers are low permeable, tight Ahmadi formations in the Wasia group of the Middle Cretaceous Age and are normally treated as one zone (Aab). The geology of the field is extremely complex with a large number of faults occurring in the Wasia group of formations.

Treatment optimization

After several acid fracturing treatments were performed, it became clear that a normal response of the treated wells was a sharp production increase followed by a slight gain in average production. However, this increase in production was hardly enough to justify these treatments in economical terms. An intensive study was performed to increase the sustained production.

A comprehensive approach to optimize a stimulation treatment can be summarized as follows:

- Collect the right information

- Analyze the information to meet stimulation objectives

- Choose the design procedure

- Execute the treatment

- Evaluate the results

- Optimize treatment design for future wells.

Fluid system review

Analyzing the pressure and rate responses of these treatments and using the published theory, the following changes in the treatment procedure were introduced:

- The pad and fluid-loss control stages were redesigned

- The acid concentration was increased to 20%

- The pre-flush was reduced to 500 gal

- A density-controlled approach was taken by weighting up the pad stage to a specific gravity of 1.1 using sodium chloride

- A 1,000-gal acid stage (closed fracture acidizing treatment) was pumped below fracture pressure at the end of the treatments.

Core study

Two different core analysis tests were performed: an x-ray diffraction test to identify the types and relative quantities of minerals in the formation sample, and a rotating disc test to measure the rate at which an acid reacts with a rock surface.

The mineralogical composition of a formation is probably the most important factor because the etching pattern is a direct result of the degree of heterogeneity in the fracture face. Any rock characteristic that contributes to heterogeneity in the formation will enhance differential etching. The physical and chemical composition of the formation rock will influence the reaction rate of the acid; as a result, some areas will be dissolved more than others. Test results indicated that the Aab zone has properties that enhance differential etching.

A rotating disc test was furthermore performed to determine the reaction rate and order of reaction. Entering these values into the computer model did not significantly influence predicted fracture half-length. The reaction rate and order did indicate a moderate reaction rate and thus a strong retarded acid system, such as emulsified acid, did not seem appropriate.

However, it was noted during these tests that the Young's Modulus was very low, i.e., less than 1 million psi. Thus an acid flow capacity test could not be performed. The low Young's Modulus indicated that one of the reasons for a fast production decline might be due to a reduction in fracture length over time. To prove the hypothesis, pressure build-up tests had to be performed after the treatment to identify this fracture dimension.

Build-up analysis

As part of the optimization process, pressure-testing analyses were commissioned. Pressure transient tests help to obtain reliable information about in situ reservoir conditions such as reservoir pressure, permeability, porosity reservoir discontinuities, and others. Pressure transient tests were run prior to the acid-fracturing treatment to obtain the necessary data to design the job effectively.

These tests were injection fall-offs or build-ups, depending on the bottomhole pressure (BHP). The analysis of post-frac pressure data from wells that were acid-fractured between June 1998 and June 1999 confirmed that the desired fracture length was achieved. Damage in the formation that limited the possible gains from an acid fracturing treatment was attributed to the poor, lengthy unloading of the wells after the acid fracturing treatments, thus leaving the fracture face damaged.

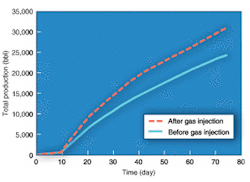

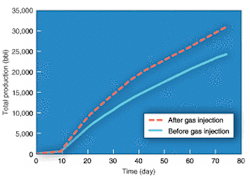

Therefore, the process of treating the wells was changed in the second half of 1999. Gas was injected in the formation for several days prior to the acid fracturing treatment to artificially increase BHP and thus improve unloading of the treating fluids. The analysis of data from these wells confirmed that the wells were being unloaded properly, avoiding the damage to the fractures after the acid fracturing treatments.

After analyzing all aforementioned data and all treatments that were performed in the past, it was now possible to summarize all gathered information and develop a candidate selection process. The following pre-job factors were taken under consideration:

It became clear that the BHP, pre-job skin, formation permeability, and availability of a CBL were the deciding factors. Wells with higher BHP, i.e., greater than 500 psi, with high skin, low permeability, and a good cement bond presented the best candidates for an acid fracturing treatment. When a BHP of below 500 psi was observed, a high rate matrix acidizing treatment using emulsified acid was recommended instead of fracturing.

Conclusion

The following conclusions were drawn from this well study:

- The use of sound engineering practices helped to increase well production.

- Build-up analyses are necessary to evaluate treatment efficiencies, i.e., fracture length, skin, etc., and draw conclusive arguments

- The well selection process is critical to improve the success ratio of the well stimulation treatments

- For depleted wells, it's recommended to establish a lower BHP limit, whereas below the limit, high rate matrix acidizing is recommended as per the maximum pumping diversion injection rate principle, and above this limit acid fracturing is used. The minimum BHP is necessary to obtain effective treatment fluid recovery

- The injection of gas before a treatment greatly improved the treatment fluid recovery and therefore future oil production due to better fracture face clean up

- The injection of gas artificially increased the BHP. The wells were thus not on vacuum, and better treatment control could be achieved

- The gas injection method could also be used for matrix acid stimulation work.

Acknowledgments

The authors would like to thank the management of Bapco and Halliburton Energy Services for permission to publish this paper. The views presented in this paper are those of the authors only and do not represent those of the aforementioned companies.

Editor's Note:This is a summary of SPE 73746.