Innovation, collaboration drive regulatory transformation

BSEE Director speaks to the agency’s programs and policy goals

The Bureau of Safety and Environmental Enforcement (BSEE) is no stranger to controversy. Ever since the Mineral Management Service was reorganized in 2010, and then in the wake of the Macondo oil spill, the agency has been in the news and in the public spotlight.

After the 2010 oil spill, BSEE introduced several new regulations designed to improve offshore drilling and production systems and processes, including the Safety and Environmental Management Systems (SEMS) rules, the Well Control Rule, and the Production Safety Rule. While the industry accepted and implemented many of these new regulations, there was significant pushback against what was perceived to be an overly harsh Well Control Rule of 2016.

It was in this context that former Louisiana state official Scott A. Angelle was selected to be the fourth director of BSEE in its existence, in May 2017. Angelle had previously served as Vice Chairman of the Louisiana Public Service Commission, as well as numerous positions in Louisiana’s State and Parish governments. In the aftermath of the Macondo oil spill, Angelle served at the request of then Louisiana Governor Bobby Jindal as liaison to the federal government, and negotiated an early end of the previous administration’s drilling moratorium.

Recently, Angelle met with Offshore to discuss BSEE’s role and remit with regard to offshore oil and gas drilling and production operations; revisions to the Well Control Rule; the growing importance of cyber security; and the rapidly emerging offshore renewables marketplace.

◆◆◆

Offshore: What is BSEE’s vision for the US outer continental shelf (OCS), and how has the bureau evolved to achieve its goals?

Angelle: Among our statutory responsibilities and our mission, we have three distinct goals or responsibilities. One of them is safety, and no doubt that is what leads us. Environmental stewardship is also very important. And the third one, which often ends up behind in the conversation, because it’s not in the name of the bureau, is the conservation responsibility we have, often thought of as the production responsibility.

The vision that we have here is that we are part of a generation of leaders here in America that believes we can have it all, but we are focusing on safety and environmental stewardship. We can indeed have robust production and that is the vision to do it all, and we are clearly demonstrating that. And as you know, 2018 was the highest oil production that we’ve ever had offshore and we had one of our safest years. So we are, again, I think delivering on that vision. We are changing the culture. This administration has made a course correction, and we are going to continue to pursue these three goals to make sure that safety leads the way.

Offshore: Daily oil production from the US Gulf of Mexico (GoM) is expected to reach a record level by the end of this year, and then again in 2020 as a wave of new projects come online. Despite this, US onshore production growth continues to outpace offshore production growth, and the pipeline of new offshore projects is declining. Can you talk about the measures that BSEE is undertaking to ensure that the US GoM remains attractive to international operators?

Angelle: Our main goal here is to make sure that the offshore marketplace is both fair and competitive, a place where folks can have a reasonable return on their investment.

We believe there are six steps to make sure that the OCS does not get left behind, when thinking about America’s energy security. The first step is to ensure that we are leading the way in safety performance and environmental stewardship. These kind of go together to me.

The second one would be access to offshore resources; and of course, that’s tied up in the courts right now. Third is regulatory and process reform. We have made some substantial changes in the regulations and have maintained safety, and we continue to work on some of our internal processes. Fourth, we are constantly looking at royalty rates. They must be competitive. What was competitive 10 years ago may not be competitive today.

Number five is engagement. We must engage with the people who are our stakeholders, whether that’s academic officials, environmental NGOs, oil and gas industry officials, or federal agencies. We must be willing to sit at the table and engage with the people in the many organizations that make up this industry. We can’t be afraid to engage. And last is tax reform, which is already on the books. So, if we do these six things exceedingly well, I am confident that the OCS can continue to make a sizable contribution to America’s energy portfolio.

Offshore: The US GoM is home to thousands of offshore platforms and related infrastructure that stretch hundreds of miles from shore and in water depths of greater than 9,000 ft. Talk about the bureau’s approach to routinely inspect and monitor such widespread installations?

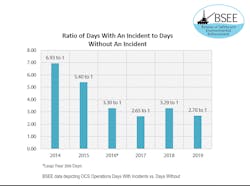

Angelle: No doubt, when it comes to offshore, we are the workplace safety organization for the country. It’s a tremendous responsibility. So, one of the things that you will be pleased to hear is that, from 2016 to 2018, we have increased our inspections by 21.5%. We have adopted risk-based inspection strategies. We have increased our safety initiatives by more than 54%.

One of the things that I noticed is that we were spending a lot of time out in the field, but not always in the most efficient way. The most expensive and potentially risky thing we do is put a BSEE inspector on a helicopter, to inspect a worksite. And I noticed that we were doing quite a bit of this. Now, visiting a site is not a bad thing in and of itself. But, I went offshore on an inspection, and the first thing that we did when we arrived was review records. We reviewed paperwork. And I thought it was odd that we would spend a two-hour flight to get to a platform to review paperwork that existed onshore, electronically.

And it appeared to me that, when we fly offshore, we ought to perform a task that we cannot do onshore. I wanted us to spend more time making physical inspections of equipment and processes than looking at paperwork – which, while very important, can be reviewed electronically onshore. I think that over a four-year period, we have saved the government about $17 million in logistics costs. And at the same time, we’ve increased the percentage of time that we do physical inspections by 8.7%.

So, we’ve been able to do more physical inspection, which is the critical thing that we need to do when we are offshore. And we have been able to save money, and we’ve been able to reduce the safety exposures for our own people. That’s a win-win.

While BSEE routinely inspects production facilities, we also inspect drilling operations, well operations, every 30 days. So, the record is clear that the country is taking its safety responsibilities very serious and the results are encouraging.

Offshore: Can you speak to the general issue of finding qualified individuals who can capably provide oversight of the offshore industry? How does BSEE recruit and look for these individuals, in general?

Angelle: We have about 830 employees, of which 124 are inspectors, and that number has been about the same for many years. It is true that many of our inspectors have come from the industry. Many of them have that frontline experience, and it’s incredible to talk to some of these folks, as they have brought that experience to the government side.

That said, we don’t have a lot of turnover on our inspector side, and we’ve been able to keep a qualified group. Soon we will be instituting a certification program for our inspectors. And so that will be another level of confidence that we will be able to bring to the American people.

And we just realigned our offshore training branch, which was headquartered in the Washington Metro D.C. area. We’ve just relocated that to the Gulf Coast. We believe it gives us some functional opportunities closer to the field and we’re excited about that. By and large, I’m very pleased with the quality of our inspectors.

Offshore: There has been a steady decline in shallow water (656 ft or less) drilling and production and in the number of active platforms on the shelf over the past 20 years. How is BSEE working to renew interest in shallow water resources?

Angelle: Last year, we had the highest oil production in the history of offshore development. But it’s clear, when you look at the numbers, that we have two distinct areas in the Gulf of Mexico: shallow water (less than 200 m) and deepwater (greater than 200 m); and the shallow-water area is in steep decline. It’s an older province. We have drilled nearly 50,000 wells since 1947, so it’s 72 years old. We’ve seen the significant decline in production activity there over the last 20 years: a 92% reduction in natural gas, 77% decline in oil, and a 73% reduction in the number of oil-producing wells.

And yet, despite this, our sister agency the Bureau of Ocean Energy Management (BOEM) tells us that they believe there are $20 billion of remaining oil and natural gas resources in the shallow-water areas, based on Oct. 1, 2019 commodity prices.

It gets complicated, because at the same time, we’ve gone through a period of about 20 years where there hasn’t been much capital deployed, nor many wells drilled, in the shallow-water arena. Many of the platforms are going from economic to uneconomic. If you can’t drill a new well, over time the production just doesn’t pay for itself. As a result, we’re seeing a significant removal of this infrastructure, and we all would conclude, from a business standpoint, that as this very expensive infrastructure gets removed, it’s highly unlikely that an investor will go back to that area and install new infrastructure.

The best time to get those remaining resources is before the infrastructure is finally removed. So, in a sense, I would say that the nation is on a shot clock. It takes an energy company’s willingness to deploy capital to go get it. Unfortunately, over the past 20 years, the industry’s record has been very clear. They have not been willing – with a few exceptions – to deploy that capital. And so, we believe that we can no longer manage the Gulf of Mexico with this “one size fits all” approach, because we do have two distinct provinces.

Offshore: The industry is keeping a close eye on the progression of the 20,000-psi developments in the US GoM. Can you talk about the new guidance that BSEE has issued for high-pressure and high-temperature developments?

Angelle: Without a doubt, these high-pressure, high-temperature reservoirs represent the new frontier for US resource development. And I also believe that, for capital to be deployed, there needs to be a predictable, reliable set of rules and regulations. There’s not a lot of stuff in the Code of Federal Regulations about it. We felt that it was necessary to take a hard look at this issue and give, not only our own employees, who review permits and processes, some sense of guidance; but also give industry some sense of predictability. This is what we believe was the guidance that was consistent with the regulations. That would give industry the confidence to spend the billions of dollars necessary to unlock this frontier.

So, we believe that the documents that we put together, particularly the Notice to Lessees, are going to serve not only America well, but also the global industry. We’re getting requests from officials from other countries to review these documents. This is an area where America should be leading, and we are.

Offshore: BSEE published its long-awaited revision to the “Well Control Rule” in May 2019; it updated the 2016 “Well Control Rule.” Can you summarize the primary changes to the rule, and how is the industry responding to it so far?

Angelle: I want to make sure that folks understand we didn’t roll back anything. We moved forward. In the aftermath of the 2010 oil spill, we received 424 recommendations from 14 external organizations who issued some 26 different reports. So, that was one of the things that I inherited – this vast set of recommendations.

The other thing that I inherited when I got here was the Executive Order signed by the President that directed us to look at the Well Control Rule, and to determine if there were any provisions that were overly burdensome, that could be adjusted without sacrificing safety or environmental stewardship. We followed those instructions using a scalpel, not a chainsaw.

We ended up making changes to about 25% of the rule that we inherited and the rest of it remained unchanged. We followed the instructions that said, “go make changes to only those provisions that are overly burdensome but do not compromise safety.”

We then took those changes and we overlaid them with the recommendations, and a group of career subject matter experts concluded, in a signed federal document, that none of the changes that we made ignore or contradicted any of the recommendations that we received in those 26 reports from those 14 external organizations. That said, we did make some substantial changes. We did eliminate some overly burdensome regulations. We looked at real-time monitoring changes. We looked at the intervals by which we would test blowout preventers. We looked at the safe drilling margin. We looked at a variety of things that were over and beyond what all of the external agencies recommended after the spill, and we were able to find those things that were overly burdensome. We didn’t decrease safety and we made the region more competitive. The idea was to keep the American offshore marketplace efficient and competitive. And, the 10-year undiscounted net savings from these changes is expected to be $1.5 billion.

Offshore: The federal Safety and Environmental Management Systems (SEMS) rules were another product of the 2010 blowout. Can you provide an update on how operators are complying with the SEMS I and II rules? Can you offer some thoughts on how you think these regulations are working, in general, to increase offshore safety?

Angelle: SEMS I and II are arguably the best of the regulations that were created and implemented in the wake of the spill. They raised expectations for the industry beyond the historical prescriptive nature. They challenged the industry to embrace a culture of safety and environmental stewardship, and we are currently analyzing the audit results of the third SEMS audit cycle. We are constantly auditing performance, and incorporating the lessons learned from that. We use the lessons learned to publish safety alerts and safety bulletins.

At the end of the day, the events of 2010 showed that there is no room for another such incident, and SEMS helps to deliver on that goal. There’s always going to be room for improvement. We need to continue to root out and reduce the rate of incidents, but SEMS is good. It’s good policy, and industry has embraced it in incredibly strong ways.

Offshore: Select operators have voluntarily committed to having their subsea assets covered by improved subsea leak detection policy before the end of 2019. Can you speak to the impetus of this initiative, and operator compliance to date?

Angelle: We have a massive amount of infrastructure in the Gulf of Mexico, and it’s been there for years, in a corrosive environment. Those facts inevitably present challenges. We need to make certain that we are raising the level of expectations. For offshore operators, having a good subsea leak detection system is good public policy. We have expressed our expectations to the operators, including our hope that they can do this in a voluntary manner. It takes a long time to go through rulemaking, but it may be necessary at some point. But first, let’s see what we can do through collaboration and innovation, and we have made a lot of progress.

We are on track to have subsea leak detection systems on 100% of the assets that operate above hydrostatic pressure. So that’s the first level that we’re looking at. And you know, industry is contemplating publishing their own standards on subsea leak detection. But at the end of the 2019, I will be getting a report that lists all of the operators, and what progress they have made toward reaching that first milestone. So far, the cooperation has been incredible.

Offshore: As more computer systems become interconnected through the “Internet of Things,” the issue of cyber security on platforms, rigs, and vessels is taking on increasing importance. What measures is BSEE taking on this front?

Angelle: The whole cyber issue is something that we need to be concerned about. Several months ago, I signed a change management initiative for our staff to begin to try to assess the risk. I think that, in some cases, we’re late to the party on understanding cyber security issues. There has been a thought that this is an issue for other agencies. I’m making a change in that regard, and now we have a dedicated group who are tasked with addressing this issue.

We are also sending out a request for more information to a small group of operators, in an effort to get a little bit better information on some of their cybersecurity risks. We are paying attention to that, because one of the things that’s worth sharing with you is that, 10 years ago, half of the OCS production came from 37 facilities. That was 10 years ago. Last year, half of the OCS production came from 11 facilities.

Let me tell you what that means. We have more production coming from those 11 facilities than we had five or 10 years ago coming from 37 facilities. Offshore production is responsible for about 17 or 18% of total US oil production; and if half of that is coming from 11 facilities, that means that 9% of the production in America is coming from 11 facilities offshore. Those facilities, to the degree that cyber issues could impact them, could impact our energy security. So, we need to be aware of those issues and try to make sure that we can mitigate them, and we’re starting to see if we can provide some leadership in that area.

Offshore: Many of your initiatives rely on data and analysis of that data. What has BSEE done to enable itself to use the vast amounts of data you have to inform your mission work?

Angelle: Part of what we’ve been able to do is develop a vital stats program here and we have, I believe, six or seven vital stats committees. Much like a doctor who is treating a patient needs to understand the vital stats, it’s important for us, as a bureau, to know what the vital stats from offshore are telling us. So, we now measure 82 unique data points on a quarterly basis and that’s the first time that this bureau in its history has been as robust in identifying its vital stats and measuring those statistics, from inspections, to permitting, to anything associated with production and incidents.

We recently established the SPEAR program, which stands for Safety Performance Enhanced through Analytical Review. And I believe there is an opportunity for us to employ artificial intelligence in all this data that we collect to determine if there are some predictive indicators. We are applying a variety of filters, if you will, to determine, as a workplace safety regulator, the trends and predictive indicators so we can then jump out ahead of the next incident as opposed to responding to yesterday’s incident. So, I think 2019 will be a breakthrough year for us in the use of data. We have a duty and a responsibility to scrub our data in incredible ways to determine if we can prevent something from happening rather than just reporting on what happened.

Offshore: Oil and gas companies are investing in renewables and in new technologies to reduce the carbon footprint of their operations. Can you talk about BSEE’s role in the regulation of OCS renewable energy development and for activities related to reducing greenhouse gas emissions from offshore operations?

Angelle: The renewable portfolio is currently split between BOEM, our sister agency, and BSEE. In April 2019, we began the funding of a 28-month research project to examine the engineering of the Block Island Wind Farm offshore Rhode Island. We believe that the data that we will get from that will help inform the design and the fabrication of future wind farm development.

You may be impressed to know that in the calendar year of 2018, compared to the calendar year 2016, BSEE staff had an increase of 193% on the number of renewable energy industrial submissions that we received. So there’s no doubt that wind energy offshore is a developing area, and there’s no doubt that BSEE and BOEM are going to be called to be those agencies to manage this.

That said, the Outer Continental Shelf Lands Act specifically limits BSEE’s oversight to oil and gas-related efforts, and it’s silent on renewables, and when things are silent on workplace safety, they de facto fall to OSHA. We went to OSHA and had a conversation with them about whether BSEE would be the best-suited agency to oversee and regulate workplace safety with regard to renewable platform facilities offshore. OSHA looked at our record and delegated that authority to us.

Now, we are consistently looking at ways that we might bring the offshore oil and gas safety regulatory regime to the offshore renewable energy industry. It’s important to know that the industry wants a regulatory regime. They want to know what the rules are. They want predictability and the reliability that comes from written regulations, as opposed to just somebody waking up on the wrong side of the bed one day and just having an arbitrary and capricious approach.

So, we are in that process, working with BOEM, on those regulations. And again, as decisions are made, and as that industry gains momentum, we’ll be right there. I would imagine that, in some period of time in the future, that our portfolio will begin to include the regulation of active offshore wind operations, primarily. And I think first of all, on the US East Coast.

Offshore: The industry seems to be embracing BSEE’s new mobile safety alerts. Talk about the origin of this initiative, and how is it driving change?

Angelle: This is something that I think is incredibly cool. It is the “BSEE!Safe” text messaging system. This comes from an idea that I had, after looking at data points. Last year, there were 68 million work hours that were worked offshore by operators and their contractors. However, when you look at the split of who’s doing what, I think we said that 90% of the work is being performed by contractors on behalf of operators.

And one of the things we know is that, our regulatory authority is limited to the operator and not to the contractor. And so, one of the things that we thought would be important would be, when we have safety information, we have safety alerts, safety bulletins, is to make sure the right people receive them. We have lessons learned that could save lives. Last year, I think we put out anywhere from 18 to 25 safety alerts.

One of the things that I thought would be pretty cool is that, rather than us issuing a safety alert to the 60 operators offshore, who would then turn and issue it to their service contractors, and then to their subcontractors – why not allow all of those parties to sign up, voluntarily, to receive that safety bulletin from us on a direct basis. And let me tell you where I got this from. I was traveling one day, and it was one of the airlines and as I was checking in at the kiosk. It prompted a question, “Do you wish to be contacted by us, during the course of this travel? If so, give us a cell number or an email address.” And I was sitting, as many do, at the gate, and as you know, there’s a lot of noise that comes over the loudspeaker there, a PA announcement for a variety of things and you begin to tune them out. It’s just so much noise. But I got a text message, as I was sitting at that gate. It said, my gate assignment had changed, and had I not got that, I guarantee you, I would’ve missed my flight. But because it came in directly to me and it wasn’t a bunch of noise, I was able to act upon it.

So, we went out and we said, “Is there a system that might comply with all the privacy laws and give folks an opportunity to sign up to receive these actionable alerts directly?” When I went to the OTC conference last May, I announced that we were starting this program. The next day, we had three people that signed up. Now, as we speak in December, I think we have 4,200 unique subscribers who are receiving these messages directly from us on these actionable safety alerts. I asked our staff to look and determine if any other industry in America or any other offshore regulator on the planet was doing this, and we determined that we are the only workplace safety regulator on the planet that is issuing, via text message, safety alerts directly to the worker. That’s using innovation rather than just regulation to drive performance. You can affect behavior, immediately. And it is amazing the positive reaction that we got from the worker who appreciates seeing those things.

And we believe, again, at the end, it’s not just about regulation. We can drive performance beyond regulation. And there needs to be regulation. Don’t get me wrong. There’s an adequate amount of regulation, but when regulation leads to strangulation, we have made America uncompetitive. So, what I like to think is that, we can drive performance through regulation, but we can also drive it through innovation, and we can drive it through collaboration. •

About the Author

David Paganie

Energy Conference Director

After 20 years with Offshore, David Paganie has transitioned into a new role within Endeavor Business Media as Energy Conference Director, effective Jan. 1, 2025.

He is still leading the event content, chairing the conference advisory boards and working with the conference teams for Offshore's events (Subsea Tieback and Deepwater/Topsides) as well as Microgrid Knowledge's events. His success in growing event content and securing senior level executives as speakers has led to him creating many of the best practices at Endeavor.

Paganie previously served as Chief Editor of Offshore magazine and Conferences Editorial Director. He oversaw the Offshore portfolio of print and digital editorial content and international oil and gas conferences. He also wrote the monthly Comment column for Offshore.

He previously served as Editor of Offshore Field Development International at ODS-Petrodata; and as an Analyst at Baker Energy. He holds a Bachelor of Business Administration degree with a specialty in finance from Ohio University.

Bruce Beaubouef

Managing Editor

Bruce Beaubouef is Managing Editor for Offshore magazine. In that capacity, he plans and oversees content for the magazine; writes features on technologies and trends for the magazine; writes news updates for the website; creates and moderates topical webinars; and creates videos that focus on offshore oil and gas and renewable energies. Beaubouef has been in the oil and gas trade media for 25 years, starting out as Editor of Hart’s Pipeline Digest in 1998. From there, he went on to serve as Associate Editor for Pipe Line and Gas Industry for Gulf Publishing for four years before rejoining Hart Publications as Editor of PipeLine and Gas Technology in 2003. He joined Offshore magazine as Managing Editor in 2010, at that time owned by PennWell Corp. Beaubouef earned his Ph.D. at the University of Houston in 1997, and his dissertation was published in book form by Texas A&M University Press in September 2007 as The Strategic Petroleum Reserve: U.S. Energy Security and Oil Politics, 1975-2005.