Sour service strength benefits

Sandvik Materials Technology (SMT) has developed a new wireline steel grade for sour service called Sanicro 36Mo. This follows an extensive period of testing, completed earlier this year.

The oil industry is working increasingly in wells with extreme downhole conditions, i.e. high pressures, high temperatures and corrosive environments. Such conditions require capabilities beyond those of standard carbon steel wirelines. SMT already has a range of austenitic wireline steels for sour service - for example Sanicro 26Mo. But the new grade represents a significant advance in performance, according to Phil Etheridge, marketing manager, product area wire.

Sanicro 36Mo is a nitrogen-enhanced, austenitic alloy with a high level of corrosion resistance to chlorides, carbon dioxide and hydrogen sulfide. With a minimum tensile strength of 270 ksi (1,850 MPa) for slicklines and 300 ksi (2,070 MPa) for logging cables, Sanicro 36Mo offers 15-20% higher breaking loads than traditional high-alloy grades.

The new wireline grade has a proof strength in the range of 85% of its tensile strength, meaning that in slickline service it can resist high loads without a permanent set of the wire. High contents of chromium, molybdenum and nickel make the alloy very resistant to pitting. These benefits can be realized either through using a smaller diameter wire to bear the same load, or using the same diameter wire to bear a greater load.

Sanicro 36Mo can be applied in some of the conditions where slickline made with super corrosion-resistant nickel/cobalt chrome alloys is currently prevalent. The cost of Sanicro 36Mo is, however significantly lower, according to Etheridge.

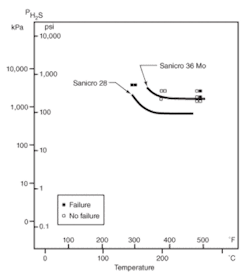

The final series of corrosion tests were aimed at establishing Sanicro 36Mo’s corrosion resistance, particularly in an H2S environment. As expected, it was shown to be located between Sanicro 26Mo and the nickel/cobalt chrome alloys.

SMT plans to offer Sanicro 36Mo wireline in a 0.116-in. dimension. The intention is that this size will take the place currently filled by 0.108-in. and 0.125-in. lines. “We can see some advantages in this ‘one size fits all’ approach, not least because many service companies use 0.108-in. lines for the regular day-to-day operations and switch to 0.125-in. for heavy jarring,” says Etheridge.

“Switching lines takes time and in some cases even switching wireline units is necessary. Using one line instead of two will mean a reduced inventory and less downtime.”•

For more information contact Phil Etheridge, Sandvik Materials Technology. Tel +46 2626 3120, fax +46 2627 4720, [email protected], www.smt.sandvik.com