High performance steam boilers to power Côte d'Ivoire FPSO

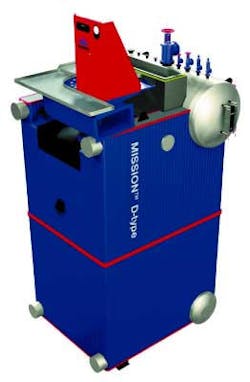

Singapore-based floating production, storage, and offloading (FPSO) vessel operator Notrans has taken delivery of two advanced steam boilers from Aalborg Industries of Jarfalla, Sweden. The Mission D-type boilers will be installed on the deck of the FPSO that will operate on the Espoir Field offshore Côte d'Ivoire for Ranger Oil. The boilers are 8 meters high - each is capable of generating 80 tons of steam per hour at 17 bar, which will be used to produce power on the vessel.

The Mission D-type boilers are gas fired but can also run on diesel fuel, if required. The design is based on the well proven top-fired two drum principle, with boilers available in a range of sizes with steam capacity from 45 t/hr to 120 t/hr. The boiler comprises a steam and water drum connected by a generating tube bank. Membrane walls form a fully water-cooled gas-tight furnace. Large unheated external downcomers welded to the drums secure natural water circulation at all loads.

Pin tubes

A standard design feature of all boilers in the Aalborg Industries range is the use of the company's patented pin tubes. Each boiler tube is surrounded by a dense array of metal pins that are welded onto it by an automated process. This creates a larger conductive surface area that provides an efficient means of transferring heat to the water within the tube. One meter of pin tubing is the equivalent of 6-8 meters of conventional tube and this superior thermal efficiency enables fewer tubes to be used. As a result, the finished boiler is lighter and more compact than other designs of comparable output and is more suitable for installation in confined spaces. An added benefit of the pin tubes is that they create a turbulent gas flow, which enhances their self-cleaning capability.

The Aalborg KBSD steam atomizing burner has been designed for large capacity applications. Through analysis with a computational fluid dynamics program, Aalborg claims to have created a unique flame structure and a geometrically optimized wind box and register design. This ensures even air distribution, minimum pressure loss and a large turndown ratio.

The furnace geometry ensures that the burner provides optimal combustion even with low quality heavy fuel.

For more information, contact Hans Matti, Aalborg Industries. Tel: +46 8 580 24300, Fax: +46 8 580 27801, E-mail: [email protected]