Retrofit technique targets improvement in produced water treatment efficiency

Offshore staff

SANDEFJORD, Norway – Stauper Offshore has developed a new method for debottlenecking and extending the life of produced water treatment systems offshore.

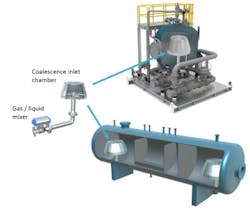

The latest generation of the company’s Compact Flotation Unit (CFU) – a gas flotation vessel for removal of oil from produced water, with a proprietary gas mixer and coalescence chamber – can now be installed into existing produced water vessels to improve separation of oil-in-water, the company claims.

Its data suggests the upgrade will enhance the vessels’ degassing efficiency.

By retrofitting existing separation vessels, operators now have a low-cost and relatively fast method for resolving brownfield and debottlenecking challenges, Stauper added.

And the vessel’s capacity rating can also be increased since the retrofitted vessel is not solely reliant on gravity separation.

“Traditional vessels like degassers, Water Knock Out drums, and other gravity-based separation vessels can be converted to highly efficient flotation vessels by upgrading with [the] technology,” said Johann Jansen van Rensburg, Stauper’s managing director.

“The vessels can be upgraded in matter of weeks, maximizing the capacity and increasing the efficiency of the existing equipment, at a fraction of the cost of replacing the equipment.”

Horizontal and vertical vessels can be retrofitted. An operator on the Norwegian continental shelf recently contracted the company to upgrade two vertical CFUs, converting them into a Stauper design.

Gravity-based separator vessels, including degassers with oil skimming features, can also be upgraded to flotation devices using the principles of this latest design.

02/09/2022