Combined cycle power plants may help offshore producers decarbonize

Over the past three decades, open cycle gas turbines have been the preferred solution for power generation in offshore production applications. Gas turbines offer several advantages over alternative prime movers, such as gas or diesel engines, including increased availability and low NOx and CO2 emissions. However, with many offshore operators making voluntary commitments to reduce their environmental footprint in the coming years, new opportunities for power plant decarbonization are being sought. Combined cycle is a concept that has been widely employed in onshore industrial applications and is now garnering interest in the offshore segment.

Combined cycle advantages

Modern FPSOs and fixed offshore production platforms have highly variable power demands – ranging from 50 to several hundred megawatts (MW). Due to their high power density, gas turbines have served as the primary means of electricity generation. On many facilities, additional turbines are also used as direct drives for required compression duties.

On all but a few production facilities in operation today, gas turbines are used in open (i.e., simple) cycle configuration, combined with some form of waste heat recovery, utilizing hot-oil or water-glycol as a heat transfer medium. In these setups, thermal energy from the gas turbine's exhaust is captured and used for heating purposes; for example, in separation and processing applications. This represents a reliable and efficient means of meeting heat and power requirements, but it does not always result in the lowest possible emissions profile for the facility.

A large portion of emissions on an offshore production facility originate from fuel combustion. But by increasing the efficiency of electricity production, the overall carbon footprint for the facility can be dramatically reduced. High-efficiency power also provides the gateway for electric motor-driven compression.

The thermal efficiency of modern open cycle gas turbine-based power plants ranges from 35 to 45%. On the other hand, combined cycle plants can have efficiencies as high as 50 to 65%, depending on topsides process heat requirements and integration complexity.

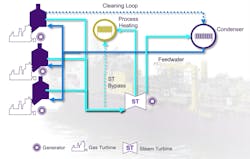

In a combined cycle system, a Once-Through Steam Generator (OTSG) extracts exhaust heat from the gas turbines (typically n+1 configuration) to convert water into superheated steam, which is then used to drive a steam turbine. The steam turbine then produces what is essentially emissions-free electricity, enabling power requirements to be met using less fuel. In addition, the combined cycle power plant can be designed such that the production of steam for fulfilling process heating requirements is prioritized and available even with a steam turbine outage, thereby minimizing the risk of disruptions to oil and gas production.

For an offshore combined cycle power plant, a vertical OTSG is preferred due to weight and footprint considerations. Unlike many other types of steam generators, such as boilers, OTSGs have once-through flow paths and do not require a steam drum or blowdown system. This reduces water inventory and eliminates the need for circulation pumps, as well as chemical cleaning. Installation is also simplified.

Other advantages include fewer piping runs and casing penetrations, lower overall weight, and lower thermal inertia. OTSGs also allow for rapid start-up and shutdown and “dry-running” capability during upset conditions, so the bottoming cycle has no impact on the availability of the gas turbines.

In some applications, the combined cycle power plant design may allow compression duties to be met with electric motors instead of gas turbines. Aside from operational advantages, such as increased availability and efficiency, and better turndown capabilities, this provides the added benefit of centralizing and optimizing emissions on the facility. It also enables more effective emissions monitoring and control.

Real-world applications

While several offshore operators have considered combined cycle power plants for their greenfield production installations in the past, very few have been implemented. However, with many organizations making formal commitments to curb emissions, interest in the concept is growing.

One of the world’s first offshore projects to feature a combined cycle power plant was Shell’s Appomattox production platform in the Gulf of Mexico. Appomattox is located approximately 80 miles off the coast of Louisiana in 7,200 ft of water and has a production capacity of 175,000 boe/d. It began producing oil in 2019 and consists of a semisubmersible, four-column production host platform, a subsea system featuring six drill centers, 15 producing wells, and five water injection wells.

Siemens Energy delivered the entire power generation package for Appomattox in 2016. The power plant features four 27MW aeroderivative gas turbine-driven generator sets and a 40MW steam turbine generator (total output ~150 MW).

Each gas turbine has an OTSG designed as a single pressure unit that recovers waste heat from the exhaust stream. They are equipped with supplementary firing, which allows for additional power production by using hot exhaust gas from the turbine as an oxygen source. In a typical setup, the burner is placed in the exhaust gas stream and is fired directly into the high-pressure superheater, leading to increased heat flow. In some instances, the turbine exhaust gas temperature can be raised by as much as 400–600°F. This ultimately results in more efficient steam production and an increase in the range/composition of fuels that can be burned.

Implementing the combined cycle power plant on Appomattox was a notable success that demonstrated what is possible when the bounds of established industry practices are pushed. Since starting up, the plant has operated well below regulations for NOx emissions while at the same time reducing fuel consumption and associated carbon emissions on the facility.

Brownfields

As it relates to brownfield conversions from simple cycle to combined cycle, one notable difference is that existing points of load and structural rigidity are set. With brownfields, it is very likely the design was completed more than a decade prior and without the intention of supporting the additional mass associated with a combined cycle power plant.

These conversion projects often require an extra level of engineering finesse, along with the utilization of lightweight materials to meet the existing limitations of the vessel. Nonetheless, converting from a simple cycle to a combined cycle plant is possible. The return on investment (ROI) from such a decision will ultimately vary on a case-by-case basis and be dictated by the facility's requirements and the operator’s objectives concerning cost, performance, and emissions.

Leveraging digitalization

While on its own, the implementation of a combined cycle power plant can yield substantial emissions and fuel cost reductions, opportunities exist to further increase savings through digitalization.

In the context of offshore power plants, it is possible to apply advanced software tools that take into account variables, such as current power demand and ambient conditions, to ensure that gas turbines are running at optimal setpoints. In this way, operators can ensure that all the units in the power plant are collectively operating in the most efficient manner (in terms of fuel consumption) relative to the current power demand on the topsides. For example, on an FPSO with an average electricity demand of 80MW being met with four 30MW aeroderivative gas turbines, just a 1% efficiency increase can equate to an emissions reduction of roughly 6,500 metric tons of CO2 annually.

Similar monitoring tools can also be used to reduce operating costs and improve the availability of gas turbines in a process known as dynamic lifing. Today, many operators use standard operating hours (SOH) as the primary metric for scheduling their turbines' service and/or overhaul activities. However, this typically assumes that the units are being operated at 100% of their rated load in an environment with constant temperature, humidity, etc. But this is never the case with offshore.

Equivalent operating hours (EOH) take into account these variables to create a more accurate picture of the turbine’s as-is condition and performance, allowing operators to be more flexible in scheduling maintenance activities. This could mean potentially pushing specific tasks that require a shutdown to a time in the future where production is not impacted. It may also be possible to adjust the turbine's operation so that the time between overhauls can be extended to a scheduled facility shutdown.

Reducing project risk

With the implementation of any new concept or novel application of established technology, there is often the perception of increased risk. This is particularly true in oil and gas and even more so in the offshore environment, where production downtime costs are magnified. In the case of combined cycle power plants, sole-source provisioning of equipment (e.g., gas turbine, steam turbine, OTSG, the balance of plant systems, etc.) can be an effective method of mitigating risks, particularly when it comes to system integration and off-design operational flexibility. Operational risks are also reduced by simplifying the optimization of the water-steam cycle.

Conclusion

The design and selection of equipment in an offshore power plant is an important decision that significantly impacts total facility lifecycle emissions. Although open cycle gas turbines have traditionally been the solution of choice across the industry, combined cycle plants are gaining traction as producers seek out new opportunities for decarbonization.

Several FPSO projects currently under development around the world are now specifying combined cycle plants. This represents a notable shift from years past and is indicative of operators’ commitment to improving sustainability. It also is a salient example of how proven onshore concepts can be leveraged to achieve emissions reductions and help the offshore industry as it drives toward a low-carbon future.

The author

Arja Talakar is Senior Vice President, Industrial Applications Products, Siemens Energy.