The offshore oil and gas industry is beginning to embrace robotic technologies as a means of improving operational efficiency, increasing worker safety, and reducing costs.

Autonomous robots are being used topsides to read gauges, detect leaks, scan the horizon, take video and audio recordings, and identify anomalies. Subsea robots are being developed that can perform a range of inspection, repair and maintenance activities.

As the industry increasingly turns to remote operations and fewer workers onboard, the deployment of these robots represents a paradigm shift in offshore operations. Some of the key technologies are highlighted below.

Quadruped robots

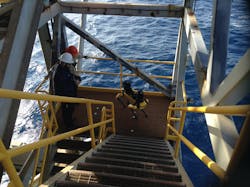

As its name suggests, quadruped robots have four legs or limbs and follow the gait patterns of quadruped animals. Their developers contend that they are the most promising among ground robots for locomotion flexibility and their ability to overcome a number of environmental and physical obstacles and challenges.

Spot, the quadruped robotic “dog” from Boston Dynamics, has seen at least two offshore deployments. One of these was in the Norwegian Sea, where Cognite and Aker BP recently deployed Spot on the Skarv FPSO. Cognite’s main software product, Cognite Data Fusion (CDF), served as the data infrastructure for the offshore test, During the test, Spot collected images, scans, and sensory readings and shared the data across the Aker BP network via dashboard to make the data actionable. Tasks included autonomous inspection, data capture, and automatic report generation. These data insights provide onshore operators with telepresence on offshore installations allowing them to conduct real-time mission planning and execute critical activities.

The mobility of Spot offshore, and the communication between the robotic dog, CDF, and Aker BP was both verified and tested. Data from Spot was available and sorted in the software in milliseconds, and Spot was remote controlled from a Cognite home office onshore, thus demonstrating how robots and digital twins can have synergies and enhance each other.

In addition, data from an operator round was collected to analyze if the sensor-stack on Spot was sufficient to comply with the proposed task.

“We are eager to explore how robotics systems can make offshore operations safer, more efficient, and more sustainable,” said Karl Johnny Hersvik, CEO of Aker BP. “The Spot offshore visit at the Skarv FPSO is one small step towards Aker BP’s vision to digitalize all our operations from cradle to grave to increase productivity, enhance quality, and improve the safety of our employees.”

Spot was also recently deployed on bp’s Mad Dog platform in the deepwater Gulf of Mexico. The operator purchased Spot to remove employees from potentially hazardous situations and physically demanding environments on offshore sites. Spot was employed by bp to read gauges, listen to equipment, scan the horizon, sniff for methane, and identifying potential leaks in hard-to-reach locations.

Using Spot to tackle these general housekeeping items, bp says, helps free up labor from this type of intensive and taxing work, and allows experienced specialists to spend their time on more complex and high-impact activities. The robot has been integrated into walking rounds to look and alert for leaks, in addition to performing online electrical inspections in areas that a human cannot safely enter. And by equipping Spot with sensors, the robot is used to go beyond human capabilities to capture IR, ultraviolet and hyperspectral data.

Before considering the robot for deployment to its offshore rigs, the bp team performed proof of concept trials where Spot was tested on gravel pads and ramps, narrow passages and confined spaces, as well as grated platforms and eventually tested in a live onshore environment.

In addition to improving worker safety, bp says it is also using Spot to improve operational efficiency, as well as to help the company reduce its carbon footprint. Using Spot to consistently gather data with sensor packages such as methane detectors and audio sensors, for example, allows bp to identify equipment abnormalities before a production facility trips occurs, ultimately reducing the amount of flaring. This includes pressure temperature readings; identifying position of values and ultimately identifying if it is open or closed; if there is corrosion, and how severe it is. The robot is also being used to gather larger data sets on equipment performance, including laser scanning, acoustic data, general visual, close visual and thermal.

Another quadruped robot is ANYbotics’ ANYmal, described by some as the “world’s first autonomous offshore robot.” ANYmal has been equipped with visual and thermal cameras, microphones and gas detection sensors that enable it to generate a 3D map of its surroundings. ANYmal can use this map to learn more about the space it operates in, and better autonomously navigate that space. The map in turn enables the robot to carry out inspections and operations more efficiently. The robot can also be remotely operated from an onshore control site to provide its human operators with real-time data.

ANYmal was first deployed on a North Sea platform in September 2018, performing 16 inspection points and carrying out a number of tasks, including reading sensory equipment and detecting leaks.

More recently, Petronas conducted a multi-week deployment of the ANYmal C robot on its Dulang B offshore platform. Petronas first field tested ANYmal C on its onshore training platforms to evaluate its inspection capabilities. The inspection tasks included general visual inspection, digital readouts of analog and digital gauges, thermography, and acoustic analysis of rotating equipment. Only after successfully passing these tests was the robot deployed on the Dulang B platform. “The offshore tests validated ANYmal’s performance under adverse conditions including slippery terrain, strong winds, and operations in day and night,” said Iskandar A. Mahmood, Manager for Robotics at Petronas. He added: “Offshore platforms have large open spaces towards the ocean that are challenging for autonomous navigation. However, the LIDAR-based localization of ANYmal has proven robust even in these cases, and we were able to successfully test all functionalities, including autonomous charging on a docking station.” ANYbotics and Petronas say they are now working to develop a specialized version of ANYmal for use in potentially explosive environments. It is expected to be placed in service next year.

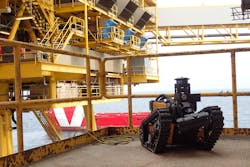

Tracked robots

In contrast to the quadruped robots, other developers have opted for a “tracked” robot that moves forward on caterpillar tracks or treads. The tracked robot has featured prominently in the industry research and development programs sponsored by TotalEnergies. In 2014, the international operating company (then Total) launched the ARGOS challenge – an acronym that stood for “autonomous robots for gas and oil sites.” The goal was to develop “the first autonomous surface robot for the oil and gas industry.” The winner of that contest, announced three years later, was the Argonaut robot developed by Taurob Inspection of Austria and Technische Universität Darmstadt of Germany.

The Argonaut was designed for routine inspections and autonomous tasks. Its successful development demonstrated that ATEX-compliant (i.e. allowed in an environment with an explosive atmosphere) robots could operate autonomously, detecting anomalies and alerting operators. The robot was deployed in the field in April 2018, first working on TotalEnergies’ onshore Shetland gas plant before being relocated to the offshore Alwyn platform.

Since then, both Equinor and the Oil and Gas Technology Centre in Aberdeen have joined the ARGOS joint industry project, a larger program that came out of ARGOS challenge. Its goal has been to develop a new autonomous robot that would be capable of performing mechanical operations. To date, the Taurob Inspector has been the result of those efforts. It can gather data, take ultra-high-definition photos and videos, record sound, and detect gas leaks. The long-range goal is to have the robot become the world’s first offshore work class robot, capable of active manipulation and mechanical tasks. Like the Argonaut, the Taurob Inspector has also been tested at the Shetland gas plant, and Equinor plans to deploy the autonomous robot at its offshore facilities, pending further tests.

Subsea robots

While some robots have been built for topsides tasks, others are being designed for subsea operations. Perhaps most notable among these is the Eelume robot, which was developed by a spin-off from the Norwegian University of Science and Technology in collaboration with Kongsberg Marine and Equinor. The Eelume robot is designed to “live” permanently underwater and perform subsea inspection, repair and maintenance tasks. The robot connects to a docking station on the seabed, which makes it easier to deploy than a conventional remote-controlled robot that would need to be sent down from the surface.

Its snakelike body affords the robot greater maneuverability underwater, allowing it to enter restricted subsea areas that would otherwise be difficult to enter with existing technology. The robot also has a modular design, with a number of tools that can be attached to it to equip it for various jobs.

“The beauty of the technology is its multi-functionality,” said Kongsberg CEO Arne Kjørsvik. “The Eelume ‘sea snake’ demonstrates the same capabilities as the cruising marine robots developed by Kongsberg in that it can operate as a slender, torpedo-shaped underwater vehicle that swims in a straight line – effectively a cruising AUV. However, its other function is that it has an extremely flexible arm that can go in and under subsea structures to manipulate valves and perform a range of offshore operations inside, say, a subsea template.”

Equinor recently reported that after extensive testing, the Eelume robot is now set for deployment at the Åsgard field in the Norwegian Sea.

Meanwhile, Houston Mechatronics Inc. (HMI) has developed the Aquanaut, an all-electric subsea robotic transformer. The Aquanaut can transform from an AUV into an ROV in less than 30 seconds, says President and CEO Nic Radford. The tetherless subsea vehicle has a working range of 200 km (124 mi); a 3,000-m (9,842-ft) depth rating; and a 24-hour endurance period.

Last year, HMI entered into a collaboration agreement with Stinger Technology AS, a move that is expected to help the company enter the Norwegian IRM market. HMI says it is finalizing product qualifications in Norway this year so that the Aquanaut can be ready for commercial applications in 2022.

Automated drilling

While most of the robots are being targeted toward operations, some vendors and equipment suppliers are looking to automate the drill floor. Notable here is the drill floor solution developed a few years ago by Robotic Drilling Systems (RDS) and Siemens. The two companies teamed up to develop a robotic technology that is designed to completely automate the drilling process. The system consists of drill floor robots, robotic roughnecks, multi-size elevators, and robotic pipe handlers. It is designed to remove high-risk manual tasks from the drill rig, while adding a new level of speed, accuracy, and reliability to drilling operations. The RDS solution is said to enable oil and gas operators to decrease rig time per well, reduce HSE incidents, and lower operating costs through consistent operations.

Replacing jobs

While robots offer the promise of increased safety and efficiency, as with other industries, they do threaten jobs. A recent report by Rystad Energy found that robots could reduce drilling labor costs by several billion dollars by 2030 – but they could also replace hundreds of thousands of oil and gas jobs globally in the same time frame.

The drilling segment of the offshore market has potentially much to gain from the adoption of robotics, since it is highly cost-intensive and involves carrying out dangerous tasks in challenging environments. Applying current supplier specs, which suggest that robotic drilling systems can potentially reduce the number of roughnecks required on a rig by 20% to 30%, the analyst estimates that such a reduction in both offshore and onshore drilling crews can bring cost savings of more than $7 billion in wages in the US alone, based on present wage levels.

Inspection, maintenance and repair operations are also ideal for robotic operations, Rystad says. Also, it is the segment where adoption of robotics has gained the most traction among operators in recent years. This has so far mainly been limited to subsea IMR activities, but IMR robotic solutions are starting to be used for topsides.

Overall, the analyst believes that at least 20% of the jobs in segments such as drilling, operational support, and maintenance could in theory become automated in the next 10 years. Looking at the current staffing headcount of some key oil and gas producing countries, the US could reduce its staffing needs by over 140,000 employees and Russia by over 200,000 personnel. Canada, the UK, and Norway could shed between 20,000 and 30,000 jobs each.

While the emergence of robotics in the oil and gas industry seems inevitable, the firm believes that full-scale adoption is still a few years away. For one thing, the firm says that the long-term reliability of the technologies in complex 3D environments such as those found on offshore platforms has yet to be fully established.

Another challenge in the implementation of robotics is limited communication capabilities, especially between robotics units, Rystad says. If robots are to fully replace humans, it is imperative that these systems communicate seamlessly to unlock true value. The implementation of such communication systems will be both complex and costly, the firm says.

Finally, job cuts due to robotics are likely to be met with some resistance from labor organizations. In addition, robotized work processes may also need to pass regulatory hurdles as authorities seek to ensure that the operational changes brought on by the new technology satisfy safety and environmental standards.

About the Author

Bruce Beaubouef

Managing Editor

Bruce Beaubouef is Managing Editor for Offshore magazine. In that capacity, he plans and oversees content for the magazine; writes features on technologies and trends for the magazine; writes news updates for the website; creates and moderates topical webinars; and creates videos that focus on offshore oil and gas and renewable energies. Beaubouef has been in the oil and gas trade media for 25 years, starting out as Editor of Hart’s Pipeline Digest in 1998. From there, he went on to serve as Associate Editor for Pipe Line and Gas Industry for Gulf Publishing for four years before rejoining Hart Publications as Editor of PipeLine and Gas Technology in 2003. He joined Offshore magazine as Managing Editor in 2010, at that time owned by PennWell Corp. Beaubouef earned his Ph.D. at the University of Houston in 1997, and his dissertation was published in book form by Texas A&M University Press in September 2007 as The Strategic Petroleum Reserve: U.S. Energy Security and Oil Politics, 1975-2005.