Robotics advances improving safety, inspection efficiency on offshore platforms

Offshore platforms of the future will need to be designed to accommodate robotic, remote, and digital technologies and operate with a minimum number of Persons on Board (POB). Use of robots will avoid the need to put people into high-risk environments, while remote transmission of data will allow decisions on asset integrity to be taken onshore without the need for staff to travel to the asset. At the same time, data analysis will provide insights into integrity-related workscopes.

Together, these methods will enhance safety and structural conditions while reducing costs and the carbon footprint offshore. Technological solutions already exist and the impact of COVID-19 will further accelerate development as regulators, operators, and service companies collaborate to remove obstacles and encourage innovation.

Various joint industry projects such as HITS (Hull Inspection Techniques and Strategy) have already established new methods for diver-less inspections and offshore maintenance. Five years ago, diver-less UWILDs (underwater inspections in lieu of drydocking) were in the early phase of development: the industry has since moved swiftly from an ROV performing visual inspections to the present situation where operators deploy sea chest cleaning tools, mooring chain measurement, and inspection of cathodic protection systems in ever harsher sea states.

It is now possible to perform a detailed inspection of critical valves, repair caissons, install impressed current cathodic protection (ICCP) systems and replace side shell structures underwater without divers. New platform designs can further facilitate these diver-less methods, with no need to accommodate as many people as in the past, and incorporating advanced launch and retrieve systems for underwater ‘resident’ robots. The robots will be designed for specific purposes with guidance systems allowing them to ‘see’ and navigate in turbid waters, operate in much harsher conditions, and self-rescue if need be to get out of trouble.

In the future, routine underwater inspections will be conducted without the need for platform visits, while onshore specialists will analyze the collected data using image recognition and machine intelligence to assess integrity and plan remedial actions.

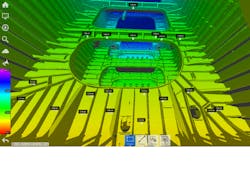

A further objective of robotic and remote methodology is to avoid the need for work at height and in confined spaces. Currently, NoMan cameras on remotely controlled arms are being used to provide class-accepted inspections of cargo tanks. However, there remains a need to measure the thickness of the internal plating, assess pitting and coating condition and confirm that the structure is not distorted – these cannot be achieved by a visual inspection alone. So, the HITS JIP is developing synchronous laser methods, which could be validated and applied commercially offshore later this year.

What this means is that, rather than putting people in tanks for days, the whole tank will be inspected, measured and trends noted in a matter of a few hours using robotic cameras and laser scanners. Where tanks are water filled, the robots will take the form of dedicated ROVs purpose designed to collect the data needed in critical areas. However, new platform designs will need to incorporate access for these systems to enter the tanks.

In future, engineers and regulators will be able to decide what information they need to determine equipment conditions and assess trends. Technicians will be robot operators using various sophisticated tools to gather data and liaise with other decision makers in real time. Access ports, garages, IT and power supplies for robots are much easier and more economic to install in the shipyard and so will be more readily introduced into new designs than on existing assets or via conversions.

Piping and electrical systems are being designed to be machine accessible so that robotic sensors can replace personnel ‘walking’ the plant, transmitting their data back to onshore control centers. Electrical systems will be inspected on a risk basis and checked internally with robots using portable x-ray systems evolved from the medical world.

EM&I discussed with a supermajor how platform design could be adapted to incorporate features for inspection of an essentially ‘not normally manned’ installation. The purpose of the study was to help the design team achieve diver-less and minimized human intervention for structural integrity inspections on the platform’s semisubmersible columns and pontoons.

Ideas included providing access via vent pipes at the top of the columns of the semisubmersible to enable resident robotic inspection devices such as NoMan, 3D synchronous laser scanners and resident mini ROVs to be remotely inserted into the columns and pontoons.

In the future, platform design will be to facilitate resident and remote methods of working, so that the operations and integrity assurance requirements will be achieved in a safer, smarter, greener, and more economical way. The technology and engineering skills already exist in many industries and simply need encouragement and adaptation to become the reality in future platforms.