Substructure modeling, analysis methodology prolongs life of Zakum offshore complex

Anne-Marie Walters, Bentley

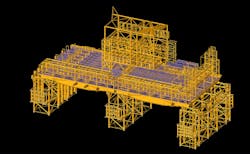

Zakum, 80 km (50 mi) offshore Abu Dhabi in the Persian Gulf, is one of the world’s largest, most productive oil fields. It is owned and operated by Zakum Development Co. (ZADCO) on behalf of Abu Dhabi National Oil Co. (ADNOC).Development to date has involved drilling 450 wells tied to around 90 platforms, with the Zakum Central Complex accommodating separation facilities, a gas treatment plant, water injection plant, power generation plant, pipeline risers and pigging traps, and associated utilities. The complex measures 375 x 46 m (1,230 x 151 ft) and comprises nine jackets, eight interconnected decks, and three riser support towers.

With the jackets installed in 1980 nearing the end of their designed operating lifespan, ZADCO initiated a structural integrity assessment for re-qualification of the structures in order to extend reliable asset life and to support continued operation of the Zakum offshore facility. As part of this process, the company needed to verify and update models independently generated by different engineering contractors and examine their design level assessments.

The project required reviewing current loading data, modifications, metocean data, marine growth profiles, inspection and corrosion information, and upgrading the models accordingly. Structural analyses using SACS and SACS Collapse were integral to ZADCO’s methodology for assessing and re-qualifying the jackets, as well as for identifying critical welded nodes and updating risk-based inspection frequency.

Dynamic substructure modeling

As ZADCO’s main offshore processing center, the deck platforms at Zakum Central Complex were loaded with numerous process modules, office units, material handling equipment, and safety apparatus, each supported by two independent jackets. The facility models, with deck and jacket models combined, were too large to accurately assess the structural analysis and life expectancy. To allow for more accurate and accelerated analysis, ZADCO separated the combined jacket and deck SACS models. The team generated the deck substructures for each jacket for structural analysis in SACS and performed non-linear pushover analysis using SACS Collapse to assess the ultimate strength of independent jackets.

Separating the originally combined models enabled structural analysis and code checks of the decks in SACS to be completed quickly without losing accuracy. Using SACS and SACS Collapse to implement a dynamic substructure modeling and analysis methodology meant that modification proposals for a specific deck structure could be easily verified and assessed without the interaction of jacket and pile structure analyses. Overall, the ability to properly de-couple the models for accurate assessment of the jackets and decks helped the team to identify individual failure mechanisms, preventing consequential facility failures, improving asset safety, and ensuring code compliance.Optimized node inspections

As part of the life extension process, ZADCO sought to identify critical welded nodes, which are essential for platform integrity, and update the risk ranking and risk-based inspection frequency. The interoperability of Bentley software allowed the project team to simulate various failure scenarios and thus to fully understand the behavior of the structural components and rank the nodes in terms of criticality. Iterative analyses and ultimate strength assessments using SACS and SACS Collapse on the independent jacket models allowed the team to measure structural redundancy and optimize the number of critical subsea nodes for inspection, which were reduced by 50%.

Exploring different strength and mitigation alternatives using Bentley’s offshore structural design and analysis capabilities brought significant time and cost savings and improved overall lifecycle asset management for the Zakum Central Complex. Prior to the project, 17 nodes per jacket (total of 153 nodes) had been identified as critical and requiring inspection. But following the life extension assessment, ZADCO identified only 76 joints as being critical for inspection, around half the original number. This allowed inspection durations to be cut from 40 to 20 days and periodic inspection costs by $165,000 per period.

Sustainable benefits

Use of SACS and SACS Collapse improved design efficiency, with fewer resource hours, reduced costs, and a shortened project schedule. ZADCO achieved a 30% reduction in engineering resources, yielded cost savings of $20,000 per jacket (a total saving of $180,000 for all nine jackets). Bentley software enabled accidental asset damage to be quickly modeled and analyzed to assess platform reserve capacity, mitigating the risks associated with platform collapse and potential marine pollution. Implementing a proactive maintenance process based on substructure modeling, accurate analysis, and asset criticality extended the structural reliability and integrity of the Zakum Central Complex for continued operation and production.

The interoperability of Bentley applications allowed the project team to evaluate multiple ways of analyzing and determining jacket strength and facilitate risk-based ranking to identify critical nodes for lifecycle asset management. Advanced structural analysis technology ensures platform robustness and safety of the onboard personnel, and eliminates costly platform repairs. Compared to conventional methodologies, the availability of separate jacket and deck SACS models improves model maneuverability for future engineering analyses. The structure decoupling solution offers sustainable benefits, saving significant time and costs in model updating and analysis, and underlines the value of this modeling methodology for managing complex mega-structures. •

The author

Anne-Marie Walters joined Bentley in 2004 as a global marketing director. In this capacity she is responsible for the marketing and positioning of the company’s solutions and products that address the needs of the industrial sector including oil and gas. Walters is a chartered chemical engineer and has spent over 30 years in the oil, gas and process industries. She sat on the board of the Engineering Contractors and Constructors Association between 2005 and 2010 and was the Chair in 2009. In addition, she is engaged in many international standards activities and is a founding member of the Process Industries STEP Consortium committee and has served on the boards of CIMsteel and the United Kingdom’s chapter of the International Alliance for Interoperability.