Deepwater construction vessel provides improved stability, novel pipelay

Jeremy Beckman

Editor, Europe

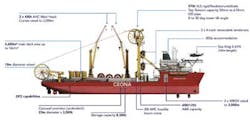

Recently, the two main cranes and vertical lay system (VLS) were fitted on Ceona's new deepwater field development vesselCeona Amazon at the Huisman yard in Schiedam, the Netherlands.

The 199.4-m (654-ft) long vessel, which will be the flagship of Ceona's growing fleet, is designed to perform in multiple pipelay and operational modes, including heavy lift and subsea construction. Its large storage areas allow it to carry 5,500 tons of flexible pipe or 8,500 tons of rigid pipe, with further storage space available on the 4,600-sq m (49,514-sq ft) main deck. This combination allows the vessel to carry sufficient quantities of rigid and flexible pipe, risers, umbilicals, or subsea structures (depending on requirements) to execute logistically complex projects in remote environments in a single trip, the company claims, minimizing the need for support cargo barges.

Lloydwerft constructed the hull at its shipyard in Bremerhaven, northern Germany. The hull is the third of a series of a proven drillship design – the others were commissioned by Noble Drilling. Ceona selected this concept because of its beneficial verified vessel response characteristics. The mid-ship moonpool is located close to the vessel's transverse axes, minimizing the impact of the vessel's motions on pipe stresses during installation. This should allow the vessel to remain in operation in relatively heavy seas and strong winds, Ceona claims. Additionally, the 8 x 13.5-m (26 x 44-ft) moonpool can accommodate the largest pipeline end termination structures.

Huisman designed and builtCeona Amazon's 570-metric ton (628-ton) top tension VLS tower, an upgraded version of a tower used by Technip on the Deep Blue, and also the twin 400-metric ton (441-ton) active heave compensated cranes. These are capable of operating in tandem to lower large subsea structures, as well as handling long and complex subsea spools. In addition, the cranes can be used to support installations of mooring spreads for FPSOs, semisubmersible platforms, and TLPs.

Most of these features are derived from proven technologies, although the combination of the various components is unparalleled, Ceona claims. One new feature is the vessel's G-lay pipelay system (patent pending), which again combines tried-and-tested components and procedures. According to a presentation by the company's design engineering lead Jay Nguyen at the Deep Offshore Technology Conference in Aberdeen last year, the welding line is traditional S-lay. However, following welding the pipe is deflected around a stern wheel and installed through a conventional pipelay tower with two tensioners and 570-ton top tension in water depths of up to 3,000 m (10,000 ft).

To verify the functionality and capability of the proposed lay spread, the design team defined an "analysis roadmap" – an eight-point sequence of activities. The first was a beam element pull-through study to estimate the level of deck tension required as pipe is pulled through the system, and the maximum loads that will be applied on the stern wheel and tower wheel. This involved building a finite element (FE) model of the system, with the tower in the vertical position and the stern wheel shifted as far as possible to produce the largest free span. Analysis suggested sag and stress in the free span will reduce as deck tension increases, at the same time allowing the pipe to conform closer to the wheel profiles.

The company then developed a shell element FE model to assess pipe buckling potential followed by a parametric study to consider a range of uncoated, homogeneous pipes with varying outer diameters as they are pulled through the lay system. Shell elements were used to model each pipe type to allow observation of pipe ovalization as the pipe is pulled through the system. Results suggested buckling would not be an issue, with peak strain during pipelay occurring in the pipe's outermost fiber as it is pulled around the lay wheels, with a marginal ovalization of each pipe as it is bent around the tower wheel.

The next step was to establish whether a heavily insulated pipe could be bent around the aft wheel. The main concerns were quantifying the impact of bare field joints on the reeling process, and the effect of the geometric and material discontinuity on the ovality of the pipe close to these joints. The company analyzed a range of pipe diameters and wall thicknesses, including a syntactic polyurethane foam heavy insulation in thicknesses of 50, 75, and 100 mm. To optimize the model, the pipe string was revised to two coated pipe joints with the bare field joint centered, connected to beam elements modeling the remaining part of the pipe string. Then Ceona extended the complexity of the models beyond just shell elements for the study to quantify the impact of bare field joints. For this, they built the models using brick elements to obtain more accurate results during the pipe plastification stages of the process. Results suggested a heavy insulation coating will lead to increased ovalization of the pipe in the bare field joint region, compared with an uncoated pipe, underlining the importance of assessing property mismatches. Ceona has taken measures to mitigate localized ovality in a separate study.

Analysis of the realistic pipe pull-through was then performed to determine the system's sensitivity to property mismatches between pipe joints, arising from variation in the manufacturing process. The study considered the impact of a variation in material yield strength, pipe wall thickness and yield to tensile ratio between adjoining pipe sections, with a back tension of 500 kN applied to represent the tension normally applied to each pipe by the deck tensioner. It involved modeling a 24.4-m (80-ft) brick element pipe length to represent two typical joint lengths, but of differing material properties to model mismatch.

One conclusion was that the mismatches result in increased ovalization in the bare field joint region, an effect most pronounced for wall thickness and yield strength mismatches. Another was that the pipe is more sensitive to ovalization when its leading length (pulled around the aft wheel first) has greater material strength or section modulus, compared with the trailing section. The company will use the results to define a full installation envelope and detailed pipelay assessment specific to each project the vessel performs.

During installation of a rigid pipeline, the pipe will be unsupported within the free span between the vessel's aft and tower wheel and also when in the catenary during installation. To determine the acceptability of these known free spans, Ceona conducted analyses of environmental loading and vessel motions in relation to the pipe's fatigue life. These suggested that fatigue would be greatest when the vessel is exposed to prolonged periods of beam seas, with wave heights at or above the vessel's weather installation limit. In practice, the company will take into account metocean data, pipe material, and joint weld properties for each individual project.

Then followed simulated bend trials, in collaboration with Cladtek International, of a range of 8-in. nominal bore carbon steel pipes of varying composition to assess strain behavior and also how deformation of the pipe wall develops during the bending process. Findings were then compared with computer simulations and finite element analysis (FEA) models of the system.

Results suggested generally good correlation. Ceona commissioned an FE software specialist to develop a parametric tool to create individual cases for homogeneous pipe, each with a specified outer diameter, wall thickness and axial tension, and also to redefine the parameters and modeling conditions specific to each pipe configuration. The resultant products reduced the time taken to construct each model from hours to less than a minute. Further software followed, developed in-house and by consultants, to extract required data for ovality, stresses and strains in the model, allowing a time history to be compiled as the pipe is pulled through the vessel's lay spread.

Finally, Ceona commissioned an independent verification of the lay system, results of which were virtually identical to the company's own FE modeling. Ceona claims comparative FEA modeling of a conventional lay spread indicates pipe ovalization similar to results for theCeona Amazon. It will devise future test schedules to define a full installation envelope and detailed pipelay assessment specific to each project.

The company plans to pitch the vessel for relatively short-term construction jobs, particularly in the deepwater Atlantic triangle region. It has been designed to reach speeds of up to 14 knots, with the 28-MW MAN-supplied power plant providing 20% better fuel efficiency than some competing vessels, according to Mark Preece, executive vice president for commercial and business development.

This was Lloydwerft's first offshore construction job. The shipyard was looking to build an offshore track record and was able to offer a competitive price, Preece said. "We are happy with the quality of the vessel and its workability, and the quality of their supply chain has been outstanding."

About the Author

Jeremy Beckman

Editor, Europe

Jeremy Beckman has been Editor Europe, Offshore since 1992. Prior to joining Offshore he was a freelance journalist for eight years, working for a variety of electronics, computing and scientific journals in the UK. He regularly writes news columns on trends and events both in the NW Europe offshore region and globally. He also writes features on developments and technology in exploration and production.