OSPRAG well capping device launched at Offshore Europe 2011

Offshore staff

ABERDEEN, UK – The Oil Spill Prevention and Response Advisory Group (OSPRAG) well capping device was recently unveiled at the SPE Offshore Europe 2011 conference.

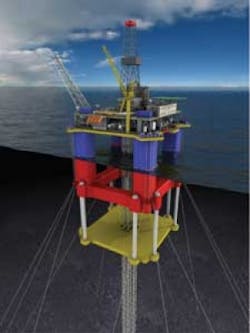

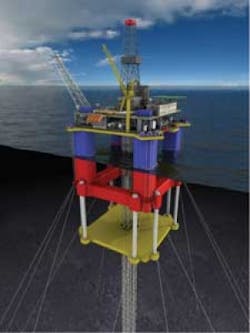

The well capping device was built in order to seal off an uncontrolled subsea well in the event of a major well control incident, minimizing environmental damage and buying valuable time for engineers to develop a permanent solution to seal the well.

The cap works by shutting in and holding pressure on an uncontrolled well and uses a choke and a series of valves which close down and stop the flow of hydrocarbons into the marine environment.

The device was constructed specifically for subsea wells in the United Kingdom Continental Shelf (UKCS). Its modular design means it can be attached to various points of subsea equipment and deployed to the widest possible range of subsea well types and oil spill scenarios which could occur, including the deep waters and harsh conditions west of Shetland.

The cap is rated for deployment in water depths down to 10,000 ft (3,048 m) on wells flowing up to 75,000 b/d at 15,000 psi. Its portable size and weight makes it relatively easy to deploy quickly from a wide range of vessels, even during short weather windows.

The capping device was designed and manufactured in seven months. This was achieved through access to pre-existing equipment systems, a streamlined project management approach and close collaboration with the industry’s global supply chain.

The device has successfully completed stringent factory acceptance and system integration testing and will be handed over to Oil Spill Response Ltd., who will store it in readiness at an operational base in northeast Scotland with the appropriate deployment capabilities.

Charles Hendry, UK Minister of State for Energy, said that “having this equipment ready to deploy in the UKCS significantly enhances our ability to deal with any incident should any occur in the basin. Prevention is always the best course however, which is why we strive for the best regulation and procedures in any basin anywhere in the world.”

James L. House, chair of OSPRAG and regional vice president and managing director of Apache North Sea Ltd, observed that “despite the fact that there has not been a major loss of well control in the UK in over 20 years of offshore operations, we believe that having such a contingency device here in the UK is essential, as it allows a quick response no matter how unlikely a scenario this is.”

Archie Smith, CEO of Oil Spill Response Ltd., said that his company was pleased to take possession of the well capping device, which he called “an important piece of equipment which would minimize marine pollution should a major loss of well control ever occur subsea in UK waters.”

The decision to construct the cap came as a result of a recommendation by OSPRAG, the body set up by the industry, its regulators and trade unions immediately following the incident in the Gulf of Mexico in April 2010.

The design development was overseen by OSPRAG’s Technical Review Group, working with BP, which agreed to project manage the detailed design, procurement and construction phases, with support from engineering services firm Wood Group Kenny. The device was commissioned by the Oil Spill Response Ltd., and was built by Cameron Ltd. in Leeds.

The device can be deployed:

• At the widest possible range of wells and oil spill scenarios which could occur in the UKCS, including west of Shetland

• To various points of the subsea stack

• At water depths of between 100 m and 3,048 m (328 ft and 10,000 ft)

• In wave heights of up to 5 m (16 ft) depending on the vessel/rig used

• From a wide variety of multi-service vessels or drilling rigs

• To wells flowing up to 1,034 bar (15,000 psi) in pressure and 121°C (250°F) in temperature

• Even where there is a high content of hydrogen sulphide present

• On to a well flowing up to 75,000 b/d.

Its dimensions are:

• Length – 4.26 m (14 ft)

• Width – 3.97 m (13 ft)

• Height – 7.14 m (23 ft)

• Footprint – 15.8 sq m (170 sq ft) if frame fully plated

• Weight – about 40 metric tons.

09/19/2011