Multilateral technique increases production in a mature offshore China field

Dennis Morgan, Mike Yuan

Phillips China Inc.

Brent Lowson

Halliburton

Located in the South China Sea, Xijiang 24-3, Phillips' first offshore China field, went into production in 1994. The field contains a layered sand/shale reservoir with poorly consolidated sand formations with a high permeability. Production rates vary from 5,000 to 18,000 b/d with the use of electric submersible pumps.

Xijiang 24-3 well A-13 was selected for sidetracking using multilateral technology to add additional reserves while maintaining the production of the existing well. At its peak this horizontal well produced a maximum of 8,500 b/d. By 1999, the production rate had declined to approximately 950 b/d. It was initially determined that a conventional horizontal sidetrack could access previously untapped reserves and potentially produce 5,000 b/d. It was also recognized that production from the original well could be preserved by using multilateral technology rather than abandoning the well, as would be the case if the it was merely sidetracked.

Objectives

The primary objective of the project was to increase the overall production of the well through the addition of a lateral by sidetracking out of 9 5/8-in. casing and drilling an 8 1/2-in. hole to the new target. Although selective flow control was required, re-entry would only be necessary to the new lateral. The production strategy involved producing the new lateral alone until the anticipated water cut increased and then bringing the original well back on line with commingled production.

One of the most critical aspects for planning a multilateral well is determining the type of junction required. This is dictated by a number of factors, principally the location of the junction and the requirements for lining the lateral, particularly with respect to zonal isolation issues and any future re-entry and flow control requirements. Although zonal isolation was required below the junction, by locating the casing exit within a stable shale formation it was evident that a technology advancement of multilaterals (TAML) level 3 type junction would be acceptable.

System description

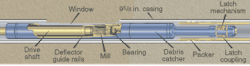

A milling system has been developed for multilateral applications, which require a high degree of precision with respect to the geometry of the window. This is particularly important where lateral re-entry is required. In applications such as this, it is vital that tools are in correct alignment with the window. Otherwise, the ability to flow the original well may be compromised.

The milling assembly, consisting of a specially designed mill and deflection tool, is set in the casing using a permanent packer. A latch coupling with an internal profile is attached below this through-bore packer and allows the milling assembly to be anchored in the well.

The system is designed to mill a window in two stages. First, the mill cuts a 7 1/2-in. opening. The tool is then unlatched by straight overpull and replaced with a hollow, sealed deflector that is run on a milling assembly. The deflector is set in the latch coupling, thereby assuring correct axial and radial placement with respect to the window. The milling assembly is then sheared off and used to enlarge and dress the window to the full width required for drilling an 8 1/2-in. lateral.

The hollow sealed deflector isolates the mainbore while the lateral is drilled. The through bore is sealed by means of a steel faceplate. Once the lateral has been drilled and lined, the faceplate is perforated to restore production from the original well. The well may then be completed utilizing conventional completion equipment.

System modifications

For this particular application, modifications to the system were necessary. Because the original well was incapable of withstanding the hydrostatic pressure of the drilling fluid required for drilling the new lateral, it was necessary to isolate it throughout the milling operation. Although the deflector provides a seal once it is installed, it was also necessary to provide temporary isolation during the initial milling operation prior to installing the deflector.

The solution to this problem was relatively simple in concept. A ceramic flapper valve installed as part of the packer/latch assembly ensured that no fluid would be lost to the well below the packer. A tail pipe incorporating a seal assembly attached to the bottom of the hollow sealed deflector was then used to break the flapper and sting into a seal bore below the packer.

After the well was killed, the electric submersible pump completion was retrieved. A gamma ray log was then run for depth correlation. After the casing was drifted, the hole was displaced with filtered seawater.

Anchor packer

The anchor packer assembly, complete with latch coupling, flapper valve, and seal bore extension, was run in the hole. A gamma ray log was run to locate the assembly at the setting depth of 1,784 m. The assembly was then oriented using a wireline survey tool to locate the exit on the high side of the hole. The permanent packer was then set hydraulically and the running tool unlatched and pulled out of the hole.

The milling assembly was run in the hole and set into the latch coupling. After the well was displaced to an oil-based drilling fluid, the 7 1/2-in. window was milled from a depth of 1,774.2 m to 1,780.1 m. The milling system was then unlatched and pulled out of the hole.

The hollow deflector, complete with seals and muleshoe, was run in the hole on a milling assembly. After the mule shoe broke the flapper, the assembly was set in the latch coupling, and the tail-pipe seals were simultaneously located in the seal bore. The milling assembly was then sheared off and used to trim and dress the window. A second mill run was required due to a low rate of penetration. This mill drilled 4 m of new formation to create a rathole for the drilling assembly.

Drilling the 8 1/2-in. lateral

The well was then kicked off with a steerable assembly, which landed the well with an inclination of 88° at 2,308 m MD. The assembly featured a new type of directional technology, whereby a "pin-down" mud motor is used in conjunction with a specially designed extended-gauge bit. This system has been shown to enhance hole conditions by eliminating spiraling. The remaining 827-m section of near horizontal hole was drilled to a TD of 3,135 m MD using rotary steerable assemblies.

Lateral liner installation

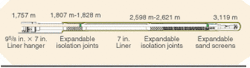

The liner, consisting of 500 m of expandable sand screens, two short sections of expandable isolation joints, and 800 m of 7-in. casing joints, was run to a depth of 3,130 m and hung off by means of a liner hanger. The screens and isolation joints were then expanded. The upper section of 7-in. liner joints ran from the liner hanger to the upper section of expandable isolation joints, thereby covering the window and deflector.

The next phase of the operations, critical to the overall success of the project, consisted of re-establishing flow from the original well by perforating through the liner and faceplate of the deflector. A 4 5/8-in. perforating gun assembly was loaded with 120 shots at a density of 12 shots per foot with 72° phasing.

Gamma ray logging correlation was used to place the guns at precisely the required depth. The guns were then fired to perforate the 7-in. casing and faceplate of the hollow deflector.

Completion

The completion was installed in two stages. First, a straddle assembly was installed across the junction to permit selective flow control and isolation, followed by the upper completion, which included an electric submersible pump.

The straddle assembly was run in the hole to a position such that the perforated interval was sealed and the sliding sleeve was opposite the perforations. The 7-in. and 9 5/8-in. packers were then hydraulically set before the setting tool was released and the workstring pulled out of the hole.

The final phase of the well construction process was the installation of the upper completion, which featured an electric submersible pump run on 4 1/2-in. production tubing and located immediately above the 9 5/8-in. packer of the straddle assembly. The well was then put on production.

After the lateral was produced for three months, it was evident that excessive water production was making the well uneconomical. The decision was made to isolate the lateral and bring the original well back on line. A plug was run on wireline and set in the landing nipple of the straddle assembly. The sliding sleeve was then opened. After clean up, the production rate was the same as that prior to construction of the lateral.

Conclusions

This first application of a new junction construction technique has added a relatively simple, low-risk multilateral solution to the redevelopment options for similar mature fields.

The well also featured the use of three relatively new technologies:

- An extended-gauge bit in combination with a pin-down motor system

- A rotary steerable drilling system

- Expandable sand screens.

The successful outcome of the project has proved the viability of combining new technologies in a multilateral application.