FLOW ASSURANCE: Vacuum-insulated tubing helps solve deepwater production problems

In the deepwater Gulf of Mexico, many production problems are caused by the transfer of heat from produced reservoir fluids into surrounding formations and casing annuli. These problems include hydrate plugging, paraffin deposition, and annular pressure buildup in the outer casing strings. Vacuum-insulated tubing (VIT), long used in Alaska to help prevent environmental damage to permafrost zones and in California to improve the efficiency of steam flooding operations, is now being utilized successfully in deepwater Gulf of Mexico wells to help solve or prevent production problems there.

VIT technology was first used to address environmental concerns associated with the development of oil fields on Alaska's North Slope, where the top 2,000 ft of the earth's crust rarely melts and is referred to as "permafrost." Production of warm formation fluids and the subsequent transfer of heat to the surrounding permafrost were identified as a potential source of environmental damage. Additionally, potential structural failure of wells due to subsidence of the melted formations was also a concern. Insulated tubing was used to prevent these potentially catastrophic problems from occurring and has had an excellent service record in North Slope applications.

VIT technology has also been applied in California steamflooding operations to facilitate production of low gravity crude oil. There, VIT delivered steam to the reservoir injection point at higher temperatures than would otherwise have been possible, thereby providing more heat transfer into the producing formation. The benefits of VIT use in the steamflooding operations include more efficient lifting costs and/or reduced loads on the steam generation systems.

As operators relentlessly pursued efficiency improvements during the 1990s, Grant Prideco's Tube-Alloytrademark product group realized that VIT could also enhance deepwater production operations. Tube-Alloy purchased the technology and equipment for manufacturing VIT and installed it in their Houma, Louisiana, tubular accessory plant in 1998 to make VIT accessible for Gulf of Mexico operations. Since that time, more than 20 strings of vacuum-insulated tubing have been manufactured and installed in the Gulf of Mexico.

The contrast in temperature between warm produced formation fluids and the cold seabed can lead to production problems if heat from the production flow is allowed to migrate outward. Foremost among these problems are paraffin deposition, gas hydrate plugging, and annular pressure buildup (APB).

Paraffin, or "wax," deposition occurs when the temperature of produced fluids falls below the wax deposition (cloud point) temperature. Buildup of paraffin slowly obstructs production tubing until remedial action is taken, which usually consists of shutting down production and using mechanical or chemical means to remove the buildup. Although this is a fairly routine operation in the life of most wells, the costs of the services in the Gulf of Mexico and lost production during shut-in can be significant. Additionally, because mechanical removal techniques require intervention into the well, the hazards of dropped objects to risers and blowout preventors must also be considered.

Methane gas hydrates are plentiful in nature and exist in a crystalline state in the cold temperatures and high pressures found on and under the seafloor. In warm reservoir fluids, gas remains in solution, and no ice crystals form. However, if produced methane and water are allowed to cool too much, crystallized hydrates will form and can cause plugging of the flow line or production string during a well shut-down or a cold start-up.

Normally operators will try to prevent this situation by filling the flow line, wellhead, and the prod-uction string immediately below the mud line with an inhibition fluid (one which has no dissolved hydrocarbon gas or water associated with it) before prod- uction starts, or by backfilling with inhibition fluid before shutting in the well. However, in some cases an unplanned shutdown can occur, and the trapped gas and water will begin to form hydrates once the produced fluids cool.

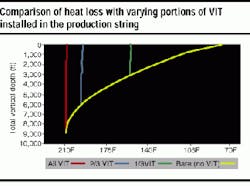

Vacuum-insulated tubing can help prevent these problems by reducing the outward migration of heat from the produced formation fluids. In VIT, fluid temperature loss is approximately 10 degrees F over 5,000 linear ft, compared to a loss of 80 degrees F or more over the same length of conventional tubing. Vacuum-insulated tubing's heat retention capability can greatly improve cold start-up/warm-up times and minimize hydrate risks.

In certain cases, VIT can replace downhole methanol injection, thus reducing the number of potential tubing leak sources. In the Gulf of Mexico, a string of vacuum-insulated tubing is typically run 3,000-4,000 ft below the mud line to provide for hot start-ups and minimize potential hydrate plugging.

Preventing casing failure

Annular pressure buildup occurs when fluids trapped between strings of casing thermally expand due to radiant heat from produced formation fluids. Because muds are composed of incompressible fluids, the thermal expansion of the trapped fluids can cause quite high annular pressures, creating the potential for rupture or collapse of casing strings or failure of casing hanger seals. In wells with surface access to the casing annuli, which includes those located on some Gulf of Mexico production platforms and most land wells, this problem is normally treated by bleeding off the pressure at the surface.

However, most deepwater (subsea, tension leg platform, and Spar) completions do not have this capability. The problem is especially acute in deep-water since production rates are higher and shallow formations are cold. These conditions are compounded by the additional casing strings required in many areas of the Gulf of Mexico due to unstable formations and shallow water flows.

Vacuum-insulated tubing mitigates annular pressure buildup by reducing heat transfer from the production flow to the fluids in the casing annuli. Typically, VIT is run from the mud line to below the deepest unstable shallow formation.

Fabricating VIT

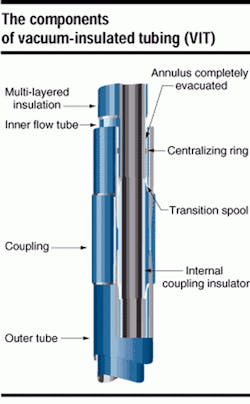

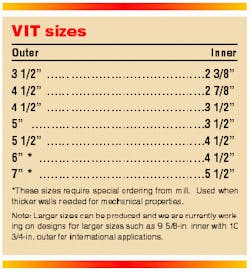

Vacuum-insulated tubing is constructed using tubes of different diameters, with the annulus between them sealed by welding and then evacuated with a vacuum pump. The threads are normally on the outside tube, with optional coupling insulators at the connections.

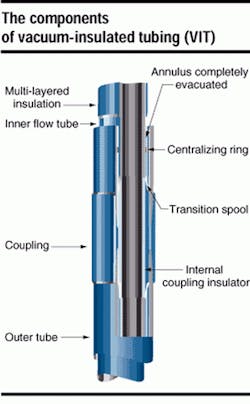

The first step in fabricating VIT is to cut both tubes to the desired length, up to 40 ft. The tubing material is typically carbon steel, but 13-chrome material is also used. Current tube sizes range up to 7 in. for the outer pipe and 5.5 in. for the inner pipe.

During assembly, a vacuum port is drilled into the outer tube, and both tubes are blasted to remove scale. The inner tube is then wrapped with foil, and hydrogen-scavenging "getter" is installed. Next, centralizers are mounted on the inner tube, which is subsequently run into the outer tube and fillet-welded in place. A vacuum pump is then attached to a port in the outer tube, and the entire assembly is run into a convection oven and heated.

The heat activates the getter, which vaporizes any contaminants in the annular space. The annulus is then voided by the vacuum pump. Upon completion of this stage, the vacuum pump is removed, the port is plugged and welded, and the thermal efficiency of the assembly is measured to verify that the desired thermal properties were achieved. Finally, the completed assembly is threaded (with premium threads, if desired) and shipped to its destination.

The structural integrity of vacuum-insulated tubing is equivalent to that of conventional tubing. However, special attention must be paid to the burst and collapse ratings, as the vacuum does not offer the resistance typical of well or annular fluids. This situation can typically be resolved through increased wall thickness or higher material yield strength.