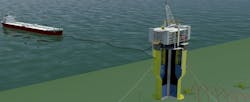

Atkins continuing refinement of deep draft floater design

Offshore staff

LONDON – SNC-Lavalin Group subsidiary Atkins has received a United States Patent (US9828072) for its marginal field deep draught production, storage and offloading (DDPSO) production facility.

This is said to be a low-capex, re-usable floating solution that can operate in harsh environments which might restrict use of small, ship-shape FPSOs.

Atkins, acquired last summer by SNC-Lavalin, already had a GB patent (GB2507370) in recognition of the DDPSO’s hull form, which it claims provides a stable platform, combining oil storage with a weight-efficient and low-cost hull.

Paul Gallagher, director for Field Development & Consulting in Engineering & Consulting, part of SNC-Lavalin’s Oil and Gas business, said: “We invented the DDPSO concept some years ago to address the economic challenges of marginal fields and its relevance in today’s market as an innovative solution to satisfy demand for ever lower capex and opex constraints is clearer than ever.”

The plan is to further develop the concept through combining Atkins’ experience in floating systems with SNC-Lavalin’s facilities engineering and project capability.

Atkins is targeting small, stranded offshore accumulations in regions with demanding export routes. Traditional FPSOs, the company says, can be costly and complexity to build where a turret system is needed to handle the moorings and flowlines.

The DDPSO’s symmetrical hull employs an ‘oil-over-water’ philosophy to store stabilized crude following processing, and therefore requires only a minimal water ballast system.

This brings savings in volume and steel-weight cost in construction, but the main point is the hull shape. The design combines hull dimensions, fixed solid ballast, and topsides mass, in a new way, Atkins claims, that, with a water-plane area selected to balance stability and a high natural period in heave, reduces motions and loads in heavy seas.

The deep draught and use of heave plates further improves the system’s response, and the resultant hull form is neither that of a conventional spar nor a circular FPSO, but combines some of the most beneficial features of each.

Ongoing development includes application to automated, remote unmanned operation. This would simplify the process facilities and reduce topsides weight, with an additional oil/water separation cell incorporated into the hull design to manage high water-cut and support produced water treatment (included within both the US and GB patents).

02/12/2018