Semisubmersible-tender assisted drilling option for deepwater development

With the emergence of the semisubmersible tender assist drilling (TAD) unit, tender assist drilling has reached a new level. Since the mid-1980s, drilling contractors and operators have modified existing semisubmer-sible mobile offshore drilling units (MODU) on a temporary basis to operate as TAD units with great success. Starting with the Seahawk MODU conversion in 1993, the semisubmer-sible TAD concept has evolved into a reliable and efficient development option for depths as great as ultra-deepwater, outperforming its mono-hull predecessors (ships and barges) by providing the following advantages:

- Better motion characteristics, which are particularly important during the rig-up/rig-down of the drilling equipment set (DES) on the platform and when transferring relatively large loads.

- More efficiency in space utilization resulting from the physical arrangement, which allows a common space for cranes to store and arrange consumables (mono-hulls often require double handling).

- Self-erection in a single moored position. Mono-hulls that self-erect often must moor beam to the platform and then move to the bow position for operation.

- Higher elevation allows easier crane access to the very tall (142 ft plus) platform.

- Better mooring and stationkeeping reliability. Mono-hulls next to platforms cannot weathervane and are very susceptible to beam loading and mooring system failure.

- Easier and safer loading to and from workboats.

- Reduced weather downtime - the Atwood semi TAD Seahawk, operating off Malaysia even in monsoon season, has never experienced operating weather downtime in eight years of operation.

Outperforming options

A semisubmersible TAD unit offers advantages over platform rigs at any water depth and over jackups in shallow water:

- Lightweight platform drilling package: The platform portion of the drilling equipment set consists only of the mast, traveling and hoisting equipment, substructure, and usually some portion of the solids control equipment. The rest, including mud pumps, engines, bulk, tubular storage, and accommodations, are on the tender hull. The resulting dry weight, compared to a platform rig, can be significantly lower.

If the drilling unit drills long and/or deep wells that require significant amounts of mud, especially more than one type, and large amounts of casing, the tender carries this load, where a platform rig must do so on the platform structure. For shallow water, this may allow a four-pile structure to be provided, rather than a six-pile or eight-pile structure.

One study in 250 ft water depth showed a savings of US$5-6 million in steel and installation costs alone. A number of studies have been done for different well types, but the total load (dry, wet, and live) for the DES is usually 3,000-4,000 kips, where a platform rig is between 9,500-15,000 kips, with the range largely determined by fluid and casing requirements.

Long lateral wells usually use three mud types (water base, mineral or oil base, and clean completion fluids). It is extremely advantageous to store these fluids at the site so they can be separated and rotated with each well, rather than offloading them and cleaning the pits with each mud change.

Deepwater and ultra-deepwater construction and installation costs are high, with each pound of reduced "payload" resulting in a US$3-15/lb capital expenditure savings. Operators have reported savings of US$100-150 million for a TAD spar over a platform drilling spar. There are other advantages:

- Smaller DES footprint: DES footprints and overhangs are approximately one- third that of a platform rig with equivalent capability. Removing the requirement for a very large drilling deck and its resulting cost is a distinct advantage for a TAD. This feature is particularly attractive in the case where an existing platform was drilled with a platform rig, but now has production equipment blocking the use of a platform rig. Older platforms that have space and weight restrictions are especially attractive candidates for the TAD.

- Speedy self-erection: Most large platform rigs require a derrick barge for erection and can take 20-30 days to completely rig up or down, even if the platform has a reasonably large crane. TAD units typically can rig-up/rig-down in three days or less.

- Accommodations and/or construction platform: With the DES removed from the tender hull, additional temporary accommodations can be installed on the deck. The Seascout, which is under conversion and a sister hull to the Seahawk, will have hotel capacity for 120 with a construction crane rated at 110 tons at 100 ft. The large deck allows space to perform construction activities, and with the large rig-up/rig-down crane, the tender is available to finish construction on the platform. The day rate of a tender hull, compared to a derrick barge, is 3-5 times less. The DES is usually designed to be shipped on large workboats, so the tender hull can arrive early, finish construction (eliminating an expensive derrick barge), and then rig up the DES. The reverse can also occur at the end of the drilling program.

- Large storage area: With the DES offloaded and plenty of deck space available, a complete well can be loaded out prior to drilling. The operator of the Seahawk loads out a complete well while completing the previously drilled well to make the best use of scheduled workboats, avoid weather-related workboat problems, and to more efficiently plan well operation.

- Well testing/extended well testing: High rate well tests require large amounts of equipment (space and deck load) and sometimes very large burner boomers with lots of cooling water. Via high-pressure hoses similar to those used in subsea completions, all the test equipment and burner booms can be readily installed on a tender. Large tanks can be put on the deck to store well cleanup fluid. Platform rigs and some jackups do not have the space or deck load to accommodate these activities.

- Auxiliary functions: Besides construction, accommodations, and well testing, the tender can be used as a staging area for workover equipment such as wireline and coil tubing units. While drilling, production equipment maintenance can be carried out along with platform maintenance, such as the installation of anodes, risers, steel repair or modifications, and coating. This is possible because of the additional deck space, living accommodations, separation of welding areas, storage capacities, and the resulting safer environment. Even temporary gas lift, water injection, and cuttings re-injection. are possible from the tender. The tender can act as a metering station for offloading crude, providing it is not stored or routed below deck.

- Independent safe haven: In the event of an emergency on the platform, the tender can act as a safe haven and as a rescue and command center. It also has the ability to pull away from the platform. This could mean the possible elimination of a standby boat and the related expense

- Increased overall operating efficiency: Two major operators report that a semisubmersible TAD operation results in a 10-25% increase in operating efficiency, compared to a platform rig. If large quantities or different types of mud are used to drill a well, platform rigs generally offload and reload each drilling fluid type as it is needed. This requires rig time to clean the mud pits. When running long strings of casing, the platform rig generally does not have space to store the casing, so some of the casing must be run off the workboat, or the platform must be completely reconfigured. This requires time and can be impacted by inclement weather. Since the platform does not have the space, workboat runs are more numerous and may be affected by weather delays as well, which can completely shut down platform operation.

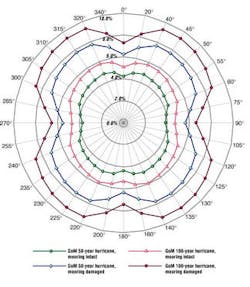

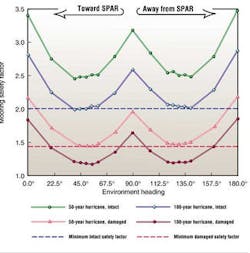

Mooring critical

Mooring and stationkeeping requirements are extremely important with a floating body next to a fixed platform. They are even more important when two floating bodies are involved. Most semisubmersible MODUs are designed to a 10- to 25-year metocean return period. However, with the proximity of the tender hull to a platform in a major event, operators have often required the mooring system of the tender to withstand the 50-year or 100-year event. In addition, a critical mooring line failure analysis for displacement toward the platform must be performed to ensure safe operations.

An all-chain or wirerope mooring system can be used in shallow water up to 600-800 ft, depending on the hull and metocean. Atwood primarily utilizes anchor chain, and on occasion, has used wirerope for pipeline crossings, suction pile anchors for short mooring line runs, and extremely non-symmetrical mooring patterns.

For water depths up to 1,500-2,000 ft, a combination system of wirerope and chain can be used. Beyond 2,000 ft, a preset taut line system must be considered with polyester and/or wirerope. In the end, the operating criteria and metocean determine the type of mooring system used.

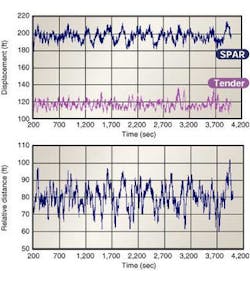

Establishing the coupled relative motion of two floating bodies next to each other is very important to determine the possibility of a collision. Analysis done jointly by Atwood and Aker Contractors shown for the relative motions of the truss spar and TAD hull is for a 10-year winter storm. This is for a taut line system with 5-in. polyester and 40 kip spring buoy in 3,200 ft. Numerous additional runs showed that the maximum coupled displacement distance between the two bodies is 42 ft. Similar analysis was also done by Atwood and Sea Engineering on their Moses tension leg platform (TLP) design and showed a total coupled motion of 35.2 ft. This is significantly less excursion (65 ft vs. 195 ft) than with the spar. The TAD hull must move with the spar's mean offset, which can be accomplished by accurate position indicators and monitoring. The TLP, due to tension leg mooring lines, requires less repositioning of the tender.

Standoff distance

It is important to determine the nominal standoff distance of the tender from the platform. The Atwood Seahawk rigs up/down at 20 ft standoff, operates at 50 ft, and is prepared to winch off location by up to 1,000 ft. In eight years of operation, the Seahawk has never been required to winch off into the standby mode.

For the truss spar, the operating standoff was determined to be 20-25 ft safety factor, plus maximum coupled relative motion between the two bodies (42 ft), plus the relative movement of the TAD hull toward the spar in the critical one-line damaged case (20 ft). This results in an 80-85 ft nominal operating standoff. This method of analysis must be done for each metocean, TAD hull, water depth, and spar/TLP configuration.

Another important consideration is the path a mooring line takes in the extremely unlikely event of a failure with a truss spar. The failed mooring line should not damage or get entangled in the truss spar's mooring line or structure. Dynamic simulation tested line failure at the TAD unit's fairleader, at the TAD side of the spring buoy, and on down the mooring line toward the anchor.

In only one case, where the wirerope failed on the TAD side of the spring buoy (the least stressed part of the line), did the failed line slightly "strum" two of the four center chain mooring lines on one side of the truss spar. This constituted no threat to the truss spar's mooring system.

In the event of an emergency disconnect from the platform, the motion compensated "man way" disconnects if the tension on it exceeds a specified limit. In the truss spar case, the man way is designed for +/- 25 ft stroke. The umbilicals have significant slack in the event of a mooring line failure and should not be over-stressed. They are designed to be disconnected within an hour or so in the event of a named storm that would require the hull to winch itself off to the standby distance.

Extensive studies, operating experience of theSeahawk, and the success of other semisubmersible TADs lead to the conclusion that such a unit can be safely and successfully employed next to a deepwater truss spar or tension leg platform.