Aker BP submits PDOs for $11.6B North Sea Yggdrasil project

Offshore staff

FORNEBU, Norway — Aker BP, Equinor and LOTOS Exploration & Production Norge have taken FID on the Yggdrasil (ex-NOAKA) multi-field development in the Norwegian North Sea, with plans for development and operation submitted to Norway’s Minister of Petroleum and Energy.

The project will develop interlinked facilities across the NOA, Fulla and Krafla licenses, located between the Alvheim and Oseberg field centers. Combined recoverable resources are around 650MMboe, with estimated overall investments of NOK115 billion ($11.62 billion).

Unmanned production platforms

Aker BP svp NOAKA Lars Høier said, “Through this development, we are setting a new standard in the way to operate a field.

“We are talking about remotely controlled operations, unmanned production platforms, new technology and data-driven decisions and work processes. We are also digitalizing project execution with our strategic partners and suppliers.”

Main above-water components of the development will be an unmanned production platform to the north developed by Equinor (Krafla UPP), and a processing platform to the south with well area and living quarters developed by Aker BP (NOA PdQ).

The latter will have low manning levels and will function periodically unmanned after a few years of operation.

As overall project operator, Aker BP will develop Krafla along with the Fulla and North of Alvheim discoveries in the same area.

Equinor discovered Krafla in 2011 and estimates the field’s recoverable resources at 325 MMboe. The unmanned Krafla platform will be remotely operated from shore and will be constructed without a helicopter deck, living quarters or lifeboats, with service operation vessels deployed for access/stays at the platform.

To facilitate data-driven decisions based on continuous monitoring of processes and equipment, maintenance planning will be optimized using digital twins, with maintenance campaign performed annually. Krafla wil be renamed Munin.

The Frøy field will be developed with a normally unmanned wellhead platform tied back to the NOA PdQ.

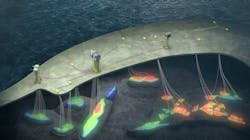

Yggdrasil’s subsea network will include nine templates and 55 wells. The gas will be exported through a shared pipeline from NOA PdQ via Krafla UPP to Statpipe, while the oil will be exported through a shared pipeline from NOA PdQ to the Grane oil pipeline.

Separate joint ventures have been formed for the oil and gas export pipelines with Equinor as operator.

All the project’s facilities will be linked to a power supply from shore, connected to the central grid is planned in Samnanger, Vestland County, with the entire development area remotely operated from an integrated operations center and control room onshore in Stavanger.

Following the submission of the PDO last Friday, Aker BP has replaced Equinor as operator of Krafla.

“One operator will be well-positioned for efficient project execution and safe and streamlined operations. This will yield greater synergies between the two developments and fewer interfaces,” Høier explained.

Alliance partners and suppliers

Among the provisional contracts awarded to date, Aker Solutions, a member of the `Fixed Facilities Alliance’ that includes Aker BP and Siemens Energy, will supply the topsides and jackets for NOA PdQ and Frøy NUI. Siemens Energy will be responsible for the electrical, instruments, control systems and telecommunications components.

And the digital collaboration between Aker BP, Aker Solutions, Cognite and Aize will continue devising solutions to improve the project’s field developments and offshore operations, with a goal of creating a next-generation field development model.

For Aker Solutions, the platforms workscope covers EPC and offshore hook-up of the 28,000-t Hugin A PdQ production platform (the new name going forward for the NOA PdQ) and its 20,500- t steel jacket substructure; and EPC and offshore hook-up of the 2,100-t Hugin B (formerly Frøy) normally unmanned wellhead platform and its 4,700-t jacket substructure.

Pending approval for the PDO from the Norwegian authorities, fabrication of the Hugin A jacket will start next summer followed by the start of construction of the platform topside in Q4, 2023. Delivery of the jacket is scheduled for 2025 and the topsides in 2026.

As for the Hugin A topside, this will be assembled at Aker Solutions’ Stord yard, and will be the largest structure of its type delivered to date by the facility. Other Aker Solutions yards participating will be those in Egersund, Verdal and Sandnessjøen, and subcontractor Leirvik in Stord will also be involved.

The Hugin B wellhead platform and its jacket will be built at Aker Solutions’ yard in Verdal.

The Subsea Alliance between Aker BP, Aker Solutions and Subsea 7 will manage the scope for the entire subsea development, with the full subsea production system including 40 standardized vertical subsea trees, Vectus 6.0 based control system modules, topside control systems, nine off six-slot templates and manifolds, wellheads and associated tie-in systems. There will also be eight static umbilicals with a total length of around 90 km.

Fabrication of the subsea production equipment will take place mainly in Norway and Brazil, supported by deliveries from the UK and Malaysia, with the steel templates subcontracted

Manufacturing should get under way in the first half in 2023 with final deliveries planned in 2028.

Subsea 7 will contribute pipeline bundles, pipe-in-pipe solutions and Swagelining polymer lined flowlines, with project management and engineering performed at the company’s offices in Stavanger, Norway and Aberdeen, Scotland.

Fabrication of the pipelines will be done at Subsea7’s spoolbase at Vigra, Norway with the bundles constructed at Wester, Scotland. Offshore operations should take place between 2024 and 2027.

As covered by Offshore last Friday, Aibel has the contract for the Krafla UPP topsides, while Hitachi Energy will supply the electrical equipment for the onshore facilities for power from shore.

Aker BP has already secured rig capacity for the development, along with critical equipment, and vessels for all major installation lifts. And Equinor, on behalf of the power from shore joint venture, has entered into an agreement with NKT for the power cable.

Floatel International’s Floatel Superior and Floatel Endurance will provide offshore accommodation services for the NOA and Krafla (Munin) topsides, following the transportation and installation of the two structures.

The contract will start in mid-2026 and has firm hire periods of seven and 10 months respectively, with options to extend.

Aker BP added that there is potential for more exploration activity in the area, and any discoveries close to the new infrastructure could be brought onstream quickly with low costs and low emissions.

12.19.2022