Industry advancing unmanned platforms, remote operations

The offshore energy industry is increasingly deploying unmanned platforms and remote operations systems to not only improve efficiency but also reduce risk exposure, costs, and emissions.

Operators are advancing unmanned platform projects offshore Norway, Trinidad, and Malaysia.

Aker BP and partner Pandion Energy are redeveloping the Hod oil field in the southern Norwegian North Sea with a normally unmanned wellhead platform. The Hod B platform will be tied-back to and remotely controlled from the Valhall field center, 12 km (7.5 mi) to the north. This past summer, Heerema’s semisubmersible crane vessel Sleipnir installed the 3,150-metric ton jacket and the 2,000-metric ton topsides. Production is expected to start in 1Q 2022. Recoverable reserves are estimated at 40 MMboe. According to Aker BP, the project will have low CO2 emissions due to power from shore.

Hod B is the second project for Aker BP’s Fixed Facilities Alliance with Aker Solutions and ABB. The first project was Valhall Flank West, which Hod B replicates.

Aker BP, Equinor, and LOTOS Exploration & Production Norge are planning a coordinated development of the North of Alvheim, Krafla and Fulla (NOAKA) area in the northern Norwegian North Sea. Aker BP is the operator of North of Alvheim and Fulla (NOA Fulla), and Equinor is the operator of Krafla.

The partners recently made a final concept selection for NOA Fulla. It is expected to feature a process, drilling and living quarters platform on NOA, a normally unmanned wellhead platform on Frøy, and three subsea templates for development of the Fulla, Langfjellet and Rind fields. The Frøy platform will be the third project for the Fixed Facilities Alliance. The platform is expected to replicate Hod B. NOA Fulla is expected to be Aker BP’s largest greenfield project to date. A final investment decision is targeted for the end of next year.

Equinor has commissioned ABB to deliver automation solutions for the unmanned processing platform (UPP) planned for the Krafla field in the northern part of the NOAKA area. ABB said it will apply its Adaptive Execution methodology. This is said to integrate expert teams, new technologies, agile processes, shared learnings and proven methodologies, linked to the digital ABB Ability platform.

The UPP is expected to be remotely controlled from an onshore control center using the distributed control system ABB Ability System 800xA equipped with Select I/O. In addition, the ABB system will monitor and control two unmanned wellhead platforms and a subsea production system. The company will develop a digital twin to simulate, test, and verify functions needed for unmanned operations on the control system, prior to installation.

Offshore western Trinidad, DeNovo Energy is developing the Zandolie gas field with a renewable energy-powered Sea Swift conductor-supported platform. Aquaterra Energy designed the unmanned minimal facilities platform to be self-powered by a wind turbine and a solar bank, with a battery for storing excess power. According to Aquaterra, the dual-energy arrangement is expected to reduce intermittency risk and eliminate the need for diesel generators for power.

In addition, the platform can be equipped with intelligent monitoring technology, so maintenance personnel should only need to visit when alerted via onshore systems. The platform is also engineered to withstand seismic activity, and to be installed via a jackup rather than a heavy-lift vessel.

The design’s reduced steel requirement and focus on using available infrastructure should help cut time to first offshore production, Aquaterra said.

DeNovo has contracted Trinidadian company United Engineering Services Ltd. to construct, install, and commission the platform. It will be installed in a water depth of 20 m (65.6 ft) and tied back to the Iguana field facilities. First gas is expected in the first half of 2022.

Sarawak Shell Berhad (SSB) and its partners Petronas Carigali Sdn Bhd and Brunei Energy Exploration have taken a final investment decision on the Timi gas project. Discovered in 2018 under the SK318 PSC, the Timi field is about 200 km (124 mi) offshore. Timi will have a new unmanned wellhead platform tied back to the existing Shell-operated F23 hub platform via a new 80-km (50-mi) pipeline. It will feature SSB’s first wellhead platform in Malaysia that is powered by a solar and wind hybrid power system. According to Shell, this unmanned platform is about 60% lighter than a conventional tender assisted drilling wellhead platform. Peak production is expected to reach 50,000 boe/d.

Finally, Petronas is converting its Resak gas production platform offshore Terengganu for remote operations. This will be Malaysia’s first platform remotely controlled from land, the company revealed in its Activity Outlook 2021-23.

The currently manned facility is undergoing conversion for remote operations via implementation of automation, robotics, and AI measures. It is expected to transition from full board offshore manning to lean manning and eventually to fully unmanned operation by 2023.

Petronas aims to duplicate the transformation process at other platforms, as part of a commitment to bring in remote and autonomous operations throughout its facilities.

Facility of the future

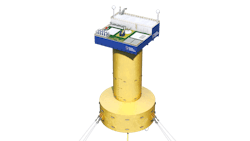

The industry is also working to expand the unmanned platform/installation concept into more complex and larger facilities. For instance, Crondall Energy subsidiary Buoyant Production Technologies (BPT) has developed floating normally unattended installation (NUI) designs/buoys concepts for a range of offshore energy developments. Configurations include: normally unattended production unit; utility buoy with renewable powering options that can replace subsea umbilicals for well control and management, and powering subsea consumers; and floating substation for use in offshore wind farms and for power import/export to oil and gas infrastructure.

Its proprietary design is a compact single column offshore facility, designed and equipped specifically for unmanned operations, with low capex and opex requirements. Features of the patented design include:

• Slender hull structure and integrated (buoyant) deck box

• Open deck for topsides process equipment and personnel access

• Deck box housing power generation and utilities

• Standardized, scalable topsides and remote monitoring solution

• Minimal motions, therefore, suitable for deployments in harsh environments.

In June 2018, BPT, on behalf of the Net Zero Technology Centre (ex-Oil and Gas Technology Centre), started the Facility of the Future study. The goal was to demonstrate feasibility of a floating NUI as a standalone production system for marginal and stranded fields in the North Sea. The company developed and tested the Production Buoy concept with Harbour Energy (ex-Premier Oil), TotalEnergies E&P UK, Lloyd’s Register, Siemens, Wärtsilä, Ampelmann, and BW Offshore. The 18-month joint industry project executed a pre-front-end engineering and design study focused on a typical North Sea field, matured the engineering design, and proved technical and economic feasibility.

According to David Steed, general manager of BPT, “We didn't need any new technologies to do this. The majority of the control and automation technologies that were needed to develop that facility were entirely understood and used offshore by the oil and gas industry already. What we really needed was a change of mindset as to how we operate and maintain these facilities. For instance, employing offshore data capture and communications to enable remote control, and remote condition monitoring of the offshore systems.”

Steed said the JIP will publish a white paper on the study’s conclusions before the end of the year.

BPT is now working to commercialize the floating NUI technology. Last year, the company signed collaboration agreements with Subsea 7 and Siemens Energy. The companies will target smaller and deepwater oil and gas fields. Siemens Energy provides the digital hardware and software necessary to enable remote control and operation for the duration of an asset’s lifecycle.

“Siemens Energy has really helped champion what we’re doing and given credibility to the overall solution,” Steed said. “With Subsea 7, we’ve got a partner that ultimately can deliver the entire engineering, procurement, construction, and installation on a project.”

About the Author

Jessica Stump

Editor

Jessica Stump is editor of Offshore Magazine. She uploads and writes news to the website, assembles surveys and electronic newsletters, and writes and edits articles for the magazine. She was the summer editorial intern at Offshore in 2009 and 2010 before joining full time in April 2011. She has a journalism degree from Texas Tech University.