Is produced water control the missing link among the top offshore emission-reduction strategies?

Key highlights:

-

Offshore’s recent reader survey found that the top three strategies for reducing offshore oil and gas emissions were CCS, methane leak reduction and flaring control, and platform electrification/power from shore.

- Produced water is a large source of emissions in oil and gas operations, historically overlooked due to reliance on associated gas for reinjection.

- Equinor's pilot in the Barents Sea will test Density Activated Recovery (DAR) technology, which uses fluid density to control water influx, on a single well with multiple assemblies.

- DAR technology can reduce facility size and the number of wells needed, lowering capex and opex.

By Ariana Hurtado, Editor-in-Chief

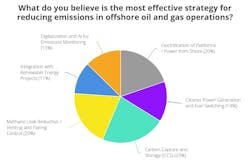

Offshore surveyed its readers—executives, engineers, consultants and field professionals—from Nov. 21 to Dec. 5 last year to inquire which strategies they believed were most effective in reducing emissions in offshore oil and gas operations.

In nearly a three-way tie, the majority of our global audience voted the following as the most effective tactics:

- CCS (23%);

- Methane leak reduction/venting and flaring control (20%); and

- Electrification of platforms/power from shore (20%).

Another 14% selected cleaner power generation and fuel switching, 13% chose digitalization and AI for emissions monitoring, and the remaining 11% voted for integration with renewable energy projects.

Produced water often overlooked

Thorleif "Totte" Lager, projects manager with Innowell Solutions AS, reached out via email to Offshore's editorial team following the conclusion of this poll. He believes CO2 taxes are effective in reducing emissions and that the poll overlooked a critical factor: produced water.

"We can always discuss the consequences of carbon emissions, but if you isolate the question, as you did in the poll, I think the most effective strategy is to impose regulatory requirements, such as CO2 taxes," he said. "Whatever hurts the bottom line will always have maximum focus, at least that is what has happened in the areas where CO2 taxes have been imposed."

Lager said produced water is the largest source of emissions in oil and gas operations due to its treatment and reinjection requirements. He added that the most effective strategy to reduce emissions is to address the root cause of produced water and that there has been a need for a technology that effectively retains the water in the reservoir. Density Activated Recovery (DAR) technology, recently qualified and set for offshore pilot testing by Equinor in early 2026, can control water influx downhole, significantly reducing emissions, costs and facility size, he said.

In this interview with Offshore, Lager explained that produced water has historically been overlooked as an emissions driver, but DAR technology, using density-based control rather than viscosity, offers a solution for autonomous downhole water management.

Offshore: You mentioned that you heard an SPE spokesperson say produced water is the largest volume waste stream in hydrocarbon recovery and a major contributor to offshore emissions. Why has this issue been overlooked compared to other emission-reduction strategies, and what makes it so critical now?

Lager: Produced water management historically received limited attention because associated gas provided an almost free energy source for high-pressure water re-injection, which both disposed of contaminated water and supported declining reservoir pressure. The paradox is that as fields mature, water production increases resulting in more injection and processing, more energy consumption, and ultimately more emissions, exactly when oil production and revenues in a field are falling.

In recent years, emissions in general, as well as those specifically associated with water handling and reinjection in hydrocarbon recovery, have been recognized as unacceptable and resulted in costly emissions-reduction schemes like those mentioned in the poll. Emerging downhole water-control technologies have the potential to provide a low-cost alternative and essential lever for reducing emissions in both offshore and onshore activities.

Offshore: How is DAR different from traditional autonomous inflow control devices (AICDs), and how do these technologies enable effective water control under reservoir conditions?

Lager: DAR is fundamentally different from conventional AICDs because it uses fluid density, as opposed to viscosity to distinguish between oil and water. Density is a physical property unaffected by pressure, temperature or flow variations, which makes DAR far more stable and predictable throughout the entire life of a well. The way density control is applied in DAR provides unique capabilities and addresses challenges encountered in most wells, such as heterogeneities, permeability contrasts, depleted zones, faults, changing flow conditions and water breakthroughs throughout the life of a well.

When applied in a compartmentalized production interval, AICDs can react to changing fluid properties and restrict flow from compartments that are producing water. In light oil reservoirs, the viscosity contrast between oil and water is minimal, rendering technologies that are dependent on viscosity ineffective, limiting their application. Conversely, a density contrast between well fluids is assured, regardless of oil grade making DAR universally applicable in horizontal wells.

Offshore: Equinor is set to pilot DAR technology in the Barents Sea. What factors led to Equinor's decision to adopt this technology, and what are the expectations for its performance in such a challenging offshore environment?

Lager: Equinor has been the global pioneer in adoption of inflow control technology, now viewing it as standard practice for horizontal wells. The next natural step for them is application of effective downhole water control, especially in challenging regions like the Barents Sea, an environmentally sensitive and remote location where subsea wells are tied back to an FPSO.

In Norway, high CO2 taxes and the energy required for water reinjection make water production and reinjection a significant lifetime cost, making technologies that reduce water production and the related emissions highly relevant to the field’s business case.

Subsea wells in deep water offer the greatest potential for DAR because interventions to address water breakthrough are rarely performed due to cost and complexity. Autonomous downhole water control allows wells to produce predominantly oil, increasing revenues while reducing operational energy consumption and emissions.

Offshore: Can you share more details about the scope of the Equinor pilot, such as the number of wells involved, anticipated milestones and how success will be measured during the early deployment phase?

Lager: The pilot is a single-well application that includes approximately 1,700 meters of compartmentalized horizontal reservoir section completed with multiple DAR assemblies in each compartment. A successful installation will advance the technology from 'ready for piloting' to a maturity level appropriate for broad deployment in the company’s global portfolio of fields and projects.

We are currently defining early-life success criteria with Equinor, recognizing that water breakthrough varies widely between wells, occurring early in some cases and many years later in others. The lower completion will also be equipped with a chemical tracer to monitor system performance and provide early indicators of DAR’s autonomous response to controlling water.

Offshore: Beyond emissions reduction, you noted that DAR technology can reduce facility size and the number of wells required. How do these operational efficiencies translate into cost savings and sustainability benefits for offshore operators?

Lager: Without water-control measures, many offshore facilities become dominated by water handling, preventing new wells from being tied in and significantly restricting field potential. Expanding processing capacity offshore is often prohibitively expensive or impossible due to space and weight limits on platforms and FPSOs.

DAR autonomously suppresses water breakthrough, enabling longer wells to drain larger reservoir sections without cross-flow issues. This increases recoverable reserves, potentially reducing the number of producers and water injectors required to drain a field, and lowers both capex and opex. Reduced water production directly reduces emissions from handling and reinjection, delivering both economic and sustainability benefits.

Offshore: In the era of energy transition, how do you see technologies like DAR shaping the future of offshore oil and gas? Could this approach become a standard for balancing hydrocarbon recovery with environmental responsibility?

Lager: DAR enables higher oil recovery earlier in field life, before water cut and reservoir depletion push carbon intensity sharply upward. By accelerating production and shortening the late-life/tail-end phase, DAR will help lower overall Scope 1 and 2 emissions, reducing the need for costly secondary recovery measures, brownfield projects and related activities. By enabling recovery with smaller facilities, fewer wells and reduced operating emissions, DAR has strong potential to become a standard technology for balancing hydrocarbon recovery with long-term environmental responsibility.

Furthermore, maintaining high oil production can provide energy companies with the cash flow needed to support renewable energy projects and the energy transition in general.

Want more content like this?

Check out Offshore's sister publications:

Oil & Gas Journal - Covering the operations of the oil and gas industry

Water Technology - News and information for industrial water management

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.