Researchers assessing measures for safe management of CO2

Editor's note: This feature first appeared in the May-June 2024 issue of Offshore magazine. Click here to view the full issue.

By Jeremy Beckman, Editor-Europe

Industry and academia are collaborating on multiple research projects to assess how CO2 might impact the various production components of future carbon capture and storage (CCS) projects. Corrosion issues could arise during transportation of CO2 through pipelines and then downhole following injection into the subsurface. And once stored, the behavior of the CO2 and its influence on the reservoir’s structural integrity will need to be carefully monitored. The Net Zero Technology Centre (NZTC) in Aberdeen is supporting some of the current programs, bringing together offshore operators, technology developers and universities to address and forestall some of the potential pitfalls.

SLB, with NZTC’s support, is devising a novel mathematical framework for adaptive surface monitoring offshore of CO2 plumes and geological integrity in a subsurface CO2 store. While established time-lapse techniques are available, there are associated reliability, repeatability, precision and cost challenges due to the long-term monitoring requirements during injection and post injection of CO2, which could be upwards of 30 years or more. The two-year, adaptive surface monitoring project, which started in May 2023, is ultimately aiming to acquire passive or active seismic from fiber deployed on the surface or by connecting to existing fiber cables.

Prior to acquiring data, SLB has built an analogue model for a southern North Sea aquifer and depleted CO2 stores to develop the adaptive survey designs and to determine detection thresholds. The fiber optic, field-acquired data should further improve understanding of distributed acoustic sensor (DAS) processing and detection levels. According to the NZTC, SLB’s approach represents a “paradigm shift away from a 4D imagining objective to a 4D detection objective.”

“The majority of the work is being done in the UK with support from global domain experts,” said Iain Martin, Technology Manager at NZTC. “Work to date has focused on simulation, modeling, and acquisition design with the aim of collecting field data to verify the simulation results. The project has support from two offshore operators that have North Sea storage and appraisal licenses and a major wind farm operator.”

Heriot-Watt University in Edinburgh recently completed a geoscientific study for the NZTC using a play-based exploration approach to identify and assess prospective levels and sweet spots for CO2 storage in the East Midlands Shelf and Silverpit basin. Both are offshore areas within the southern North Sea. The program had support from five operators which contributed data, personnel and domain expertise. The ultimate goal was to compile a fully risked and ranked prospect and lead inventory based on geology and geophysics, and a set of criteria for common risk segment analysis.

However, the main impact of the project will be to provide the basis for detailed assessment of future CCS projects. Through identifying suitable natural gas fields in the Permian Leman sandstone formation (geologically the safest sites for CCS in the southern North Sea), the study should help determine the locations that will satisfy 5% of the UK’s 2050’s CO2 storage requirement of 180 MM tons, based on the 2019 Committee on Climate Change Net Zero – Technical report.

Heriot-Watt is also leading a quantitative risk-based well assessment project concerning the integrity of new and legacy CCS wells. The UK has an estimated 78 GT of CO2 storage capability in offshore assets. However, the thousands of exploration, appraisal, producer and injector wells that either have been or will be P&A’d present a risk to the containment of CO2 in CCS projects through providing potential leak paths to the surface. So there is a need to accurately determine the leakage risk when assessing a mature hydrocarbon field or saline aquifer for CO2 storage. In this project, Heriot-Watt is looking to adapt and validate its proven risk-based analysis tool for P&A’d wells to include the impacts of long-term exposure of wells to CO2, providing operators, investors and regulators with greater confidence in the safe and long-term containment of CO2 in designated CCS sites.

“The industry partners in this project are providing information to assist in the development of the tool,” Martin explained, “including case studies concerning depleted fields and saline aquifers. This is a unique element and the key to the success of many NZTC projects. By collaborating with industry and having access to data that is not in the public domain, the technology development can be accelerated and better address industry challenges, providing a solution that meets industry requirements. The project has completed the first two milestones, updating the geomechanical and geochemical models to account for the impacts of CO2 on the wellbore, and is currently modeling the impact of corrosion on the wellbore. The final milestone will be to integrate all three models into a fully coupled model and tested on the supplied industry data.”

Another ongoing NZTC-supported initiative is the JIP, “Qualification of an SSSV [Subsurface Safety Valve] for Injection of CO2.” SSSVs are installed in the wellbore to ensure closure and isolation of the wellbore should an emergency situation, leak, damage, or system failure occur. While they will perform the same functions in CCS wells, conditions will be different with the valves subjected to low temperatures (-25 to -78°C) and lower pressures, with the risk of CO2 boil-off in the event of objective barrier failure. While SSSVs will perform the same functions in CO2 storage, current versions are not rated below -5°C, and there are no standard or regulatory-driven requirements for valve qualification for use in CCS settings.

The JIP is seeking to develop a qualification protocol for SSSVs for low-temperature CO2 service. Goals include improved understanding of the performance capabilities of well components at low temperatures; demonstrating satisfactory performance of a hydraulically-operated SSSV for use in low temperature service applications as approved by the JIP’s nine partners; design, build and test six valves ranging in size from 3 ½-in. to 5 ½-in., capable of survival in -78°C up to a maximum ambient temperature of 80°C. For the 18-month program, which started in December 2022, SLB, Halliburton and Baker Hughes each undertook development of two sizes of SSSV based on these requirements, performing testing at their designated test facilities. Results from the tests will be used to make an amendment to API14 standards, Martin added.

Finally, Ai Exploration is developing a sensor to measure moisture in real time to ppmv levels in a CCS process stream generated by multiple industrial emitters. Flue gases in the CO2 will contain contaminants, including water: in the free water phase, the CO2 may dissolve, leading to the formation of carbonic acid, corrosion, leaks, and pipeline failure. Current techniques for monitoring moisture may not be adequate to deal with phase transitions, constantly changing concentrations of impurities, high pressure and real-time data demands.

The Ai Exploration sensors would be integrated throughout the CCS network, issuing an alert if the moisture levels in the CO2 stream have exceeded specifications: this would allow the operator to take immediate preventative action, including pipeline load balancing. The optical technology works by providing real-time, data-driven chemical composition identification and qualification of moisture. Sensing optics are embedded in structurally secure probes designed for direct integration into the CCS pipeline.

NZTC is co-funding the development, which could eliminate the need for complex extractive systems, through its open innovation program. Tests will be conducted in a laboratory using a flow loop that would replicate anticipated operational conditions, the aim being to progress the technology to TRL6 ahead of a field trial followed by deployment for onshore pipelines and transportation systems. The technology is said to be insensitive to changes in operating conditions, pressure, temperature, and flow rate, enabling more accurate real-time measurement and monitoring during CO2 transportation.

The AiX sensor would monitor the moisture content in the onshore pipeline network and verify specification prior to entering an offshore pipeline. “The key thing here is that the CO2 stream is dry prior to entering the offshore network and that is the value of the AiX sensor,” Martin stressed, “since the impact of corrosion and repair offshore is significantly higher than in an onshore environment.”

CO2 release monitoring

The Strategies for Environmental Monitoring of Marine Carbon Capture and Storage (STEMM-CCS) project, funded via the European Union’s Horizon 2020 program, has performed the first controlled sub-seafloor release of CO2 at a location close to Shell’s Goldeneye platform in the UK central North Sea. The project, which brought together researchers from 14 institutions with Shell as the lead industry partner, addressed approaches, methodologies and technologies that could support environmental monitoring of future offshore CCS sites.

The controlled release program, said to be the first of its type in real life conditions offshore, simulated a CO2 reservoir leak scenario and demonstrated that the leak could be successfully detected and quantified using the instruments and tools developed during the campaign. Results also confirmed the feasibility of modeling and assessing the local, regional and wider impacts of different reservoir CO2 leak scenarios, including the part fluid pathways in the shallow subsurface might play in reservoir integrity.

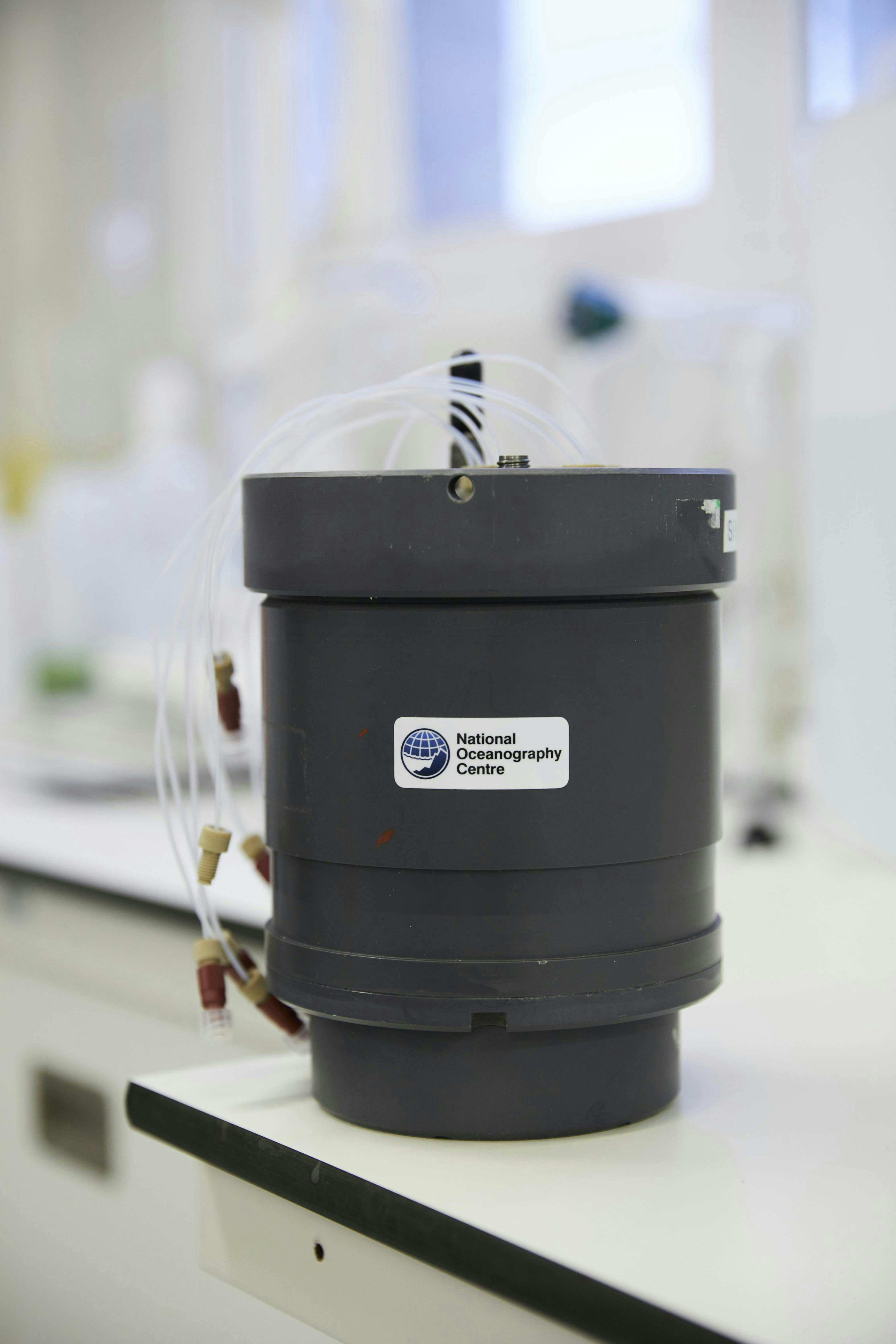

One of the participating institutions was the National Oceanography Centre (NOC) in Southampton, England, which developed miniaturized chemical sensors to measure nitrate, phosphate, pH, total alkalinity and dissolved inorganic carbon in situ, and optodes to determine pH and pCO2 values in the water column and in seafloor sediment. The instruments were designed to process measurements quickly with minimal power consumption, making them suitable for future long-term deployments. Other NOC instruments provided chemical measurements at the seafloor to determine how much CO2 entered the water column in the dissolved phase.

According to Allison Schaap, Associate Head of Ocean Technology and Engineering at the NOC, the Centre adopted the same approach for a recently completed study for the Project Greensand CCS pilot in the Danish North Sea: using chemical sensors to monitor for signatures of excess dissolved CO2 by continuously analyzing the water chemistry. The lander for Greensand, which supported both the NOC’s sensors and acoustic instruments from the University of Southampton, was larger and more physically robust than the ROV-deployed lander used for STEM-CCS. This should allow it to survive more energetic deployment conditions and a longer period on the seafloor in future operations.

“For the chemical sensors, we’ve done some design work to create a new version which decreases their consumption of consumables (e.g. chemical reagents and power) to ensure that they can be used for a longer deployment, which decreases the frequency of planned maintenance activities. We’ve also been focusing on a narrower, prioritized set of chemical parameters, based on the lessons we learned in STEMM-CCS. Lastly, we’ve been evaluating instruments from multiple suppliers for the complementary commercial sensors to maintain robustness to any supply chain issues.

“The University of Southampton have been developing acoustic tools to detect gas bubbles. They have been working to reduce the power consumption of this technology so it can be used underwater for longer, and to validate its performance and improve data analysis techniques. The two approaches are quite complementary: if there were to be a release of CO2 underwater, this could emerge as gas bubbles, but these rapidly dissolve. The acoustics detect gas bubbles, and the chemical sensors detect dissolved CO2, so with the combination we can be confident we’d detect either form. We’re in ongoing discussions with the Greensand partners about how we can continue to be involved, as they look to move on to the next steps.”

About the Author

Jeremy Beckman

Editor, Europe

Jeremy Beckman has been Editor Europe, Offshore since 1992. Prior to joining Offshore he was a freelance journalist for eight years, working for a variety of electronics, computing and scientific journals in the UK. He regularly writes news columns on trends and events both in the NW Europe offshore region and globally. He also writes features on developments and technology in exploration and production.