DRILLING & PRODUCTION

Jim Redden • Contributing Editor

Just how far will they go?

As BP prepares to inaugurate its Liberty ultra extended reach drilling (ERD) program in the Beaufort Sea, expected to shatter all global ERD records, Dr. Jerome J. Schubert, for one, suggests it may not be a long-standing milestone.

“I have no idea where the limits are (in ERD drilling),” says the assistant professor and holder of the Larry Cress Faculty Fellowship in Petroleum Engineering at Texas A&M University. “Certainly, torque and drag is an issue in these ultra long wellbores, but the technology is definitely there to continue to extend the reach.”

This summer, BP began a seismic survey to support a technologically advanced drilling program scheduled to begin in 2010 with a specially designed arctic drilling rig. Plans call for up to six ultra ERD wells, which would be four producers and two injectors. The wells, guided by 3D seismic imagery, will extend 2 mi (3 km) deep and as far as 8 mi (13 km) out into the Beaufort Sea off Alaska.

In what BP Alaska President Doug Suttles said late this summer “will set a new standard for arctic oilfield engineering and development,” Liberty will be developed from an existing satellite pad that is part of the Endicott field. Liberty will include no offshore platform, drilling island, or subsea pipeline. “These will be the longest wells ever drilled, and will allow us to develop a new offshore reservoir with the least environmental impact,” Suttles said.

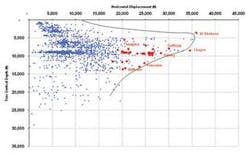

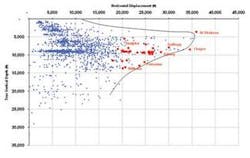

Over the past year, offshore ERD records have come and gone seemingly overnight. Exxon Neftegas Ltd. held the record earlier this year when its Z-12 in the Chayvo field off the Sakhalin Islands, which at one time held 17 of the world’s 32 longest wells, was completed at a reach of 7 mi (11 km). That record lasted four months until Maersk Oil Qatar drilled BD-04 on the Al Shaheen field to a current world record length of 7.6 mi (12.2 km).

While some may see the flurry of ERD wells as a classic case of one-upmanship, Schubert says it all comes down to technology and economic justification.

“It kind of gives them bragging rights, but there has to be a sound economic basis for doing it. Either they are very confident something is there, or they are trying new technology, which in itself is justification. While high prices make operators more willing to take the risks, new technologies also have helped reduce the costs of these wells. Many of these projects would not have been economically viable five or 10 years ago.”

MPD gains steam in HP/HT wells

Employing managed pressure drilling (MPD) to mitigate the inherent risks of high-pressure, high-temperature (HP/HT) wells is gaining popularity worldwide, says At Balance with Smith, which recently completed its third such project in the North Sea.

At Balance Director of Marketing Paul Fredericks says the tight hole in the Dutch sector of the North Sea represents a growing trend to use MPD to control pressure in HP/HT wells. Critical to the success of MPD applications in these wells, he says, is accurate hydraulic models to compensate for the loss of real-time data from pressure-while-drilling (PWD) tools that are unable to function in extreme downhole temperatures.

“With today’s prices, operators are looking more and more at HP/HT wells and it’s not just in select locations, but across the globe, from the North Sea to the Gulf of Mexico. They see MPD as a viable means of reducing some of the risks of drilling these wells,” he says.

At Balance with Smith supplies Automated Pressure Drilling services and is the exclusive provider of the Dynamic Annular Pressure Control system for real-time managed pressure drilling. At Balance also offers automated systems to maintain constant bottomhole pressure throughout drilling. The ability to dynamically control and respond to pressure changes improves drilling efficiencies by reducing potential problems such as stuck pipe and wellbore instability.

BOT sets gravel pack milestone

Baker Oil Tools advanced sand control technology, in tandem with the new generation Baker Hughes Inteq PERFFLOW reservoir drill-in fluid (RDF) system, established a world water depth record for a horizontal gravel pack from a floating drilling rig.

The Baker Oil Tools EXCLUDER Extended Longevity Well Screen and the PERFFLOW RDF system were used in two horizontal completions in 2,539 ft (774 m) and 2,798 ft (853 m) of water, respectively, in Petrobras’ Marlim field offshore Brazil. During initial production, one of the wells achieved a maximum rate of 21,567 b/d of oil.

Baker Oil Tools says its EXCLUDER screen provided mechanical robustness and plugging resistance, while the PERFFLOW RDF prevented formation damage while depositing a filter cake that would remain in place during gravel packing, which was validated by return rates greater than 90%.

Additionally, gravel packing the annulus increased the options available to control the inflow of unwanted fluids into a long horizontal well. Further, the deposited filter cake required no post-job acid treatment. Precise gravel placement and close control over pumping also were cited as critical to success. Theoretical gravel placement volume was 97% and 156% for the two wells, indicating excellent packing efficiency.

SLB unveils fracture treatment service

Schlumberger has released its new StimMORE fluid diversion service for diverting fracture treatments along a wellbore in cemented or openhole completions.

StimMORE is suited to shale formations and horizontal wellbores, both cased hole and open hole, up to 250° F (121° C). The diversion slurries can be pumped on the fly as part of the main treating fluid, diverting the fracture as needed based on the real-time integration of microseismic data.