Rigless, screenless completions solve sand problems in two offshore fields

Enzo Pitoni

Giuseppe Ripa

Eni SpA Agip E&P

Norbert Heitmann

Schlumberger

A new screenless completion technique provides a cost-effective alternative to conventional sand control methods. Correctly engineered and installed, this completion will:

- Control formation sand production and fines migration

- Increase hydrocarbon production rates and reserves

- Eliminate a rig-based operation and screens and their associated hardware.

Screenless completions reduce completion costs and enhance well productivity by combining proven techniques that may include some or all of the following:

- An optimized perforating strategy that includes design factors such as phasing, hole size, shot density, and interval length

- A procedure designed to consolidate the formation in the near wellbore area

- A tip screenout (TSO) hydraulic fracture treatment with pinpoint placement of the appropriate pad, fluid, and proppant type and size

- Proppant flowback control provisions, usually using a resin-coated proppant, a fiber additive, or both, to ensure that the proppant remains in the fracture after closure and during production.

The screenless sand control technique can be used as a primary completion for new wells or sidetracks that are expected to produce formation sand. For existing wells, it offers a cost-effective remedial operation:

- Wells or zones without gravel packs

- Sand control completions with eroded or corroded screens or plugged gravel packs

- Existing wells with bypassed zones in which circumstances prevent screen installation.

This is the conclusion of a two-part article that began in the June issue of Offshore. The first article's case study was a newly drilled sidetrack that was completed successfully using a screenless completion in J.M. Huber Corp.'s South Timbalier block 21 field, offshore Louisiana, in the Gulf of Mexico, where sand production historically has been problematic.

Second case study

The second case study discusses how Eni SpA Agip E&P used screenless completions in several of its Adriatic Sea wells offshore Italy to address sand problems that included plugged or failed gravel packs and sand screens, which had reduced significantly hydrocarbon productivity during the past few years.

Many of these gas reservoirs consist of low-to-moderate permeability sediments interbedded with sand, silt, and clay. Increasingly laminated and stratified sediments have been encountered in wells more recently drilled in this area. As a result, the completed wells often have several sublayers that are grouped into pools. In addition, many of these offshore fields have required some kind of sand control because problems associated with sand and fines production occurred either early on or later in the producing life when factors causing sand production emerged, mainly reservoir depletion. When gravel packs and sand screens became plugged with sand, Eni Agip sought improved, reliable, and cost-effective re-completion practices for its Adriatic fields, many of which consisted of more than 10 separate laminated pools.

The Giovanna field experienced sand prod-uction early in its life. The field consists of laminated, dirty sands exhibiting low average relative gas permeabilities (12-md), a d50 average grainsize of 35 microns and a clay content as high as 50%. The nature of the producing formation caused the productivity in many wells to decline as fines production began plugging the gravel packs that were installed initially in the field.

In recent years, frac and pack completions have been used to reduce sand and fines production and increase gas productivity by connecting multiple sandstone layers, bypassing near wellbore damage and decreasing fluid velocity in the formation. However, many of the wells are dual string completions whose geometries prohibit screen installation as an efficient remedial means to stop sand.

Testing the screenless completion

Because downhole well geometries prevented screen use, it was necessary to search for alternative completion approaches. After careful review, the joint Agip/Schlumberger completion team decided to test the screenless completion as a viable remedial method. Screenless completions are of particular interest for wells completed with dual strings, a common completion practice in Adriatic fields such as Giovanna, because their successful application would allow low cost development of multiple layers via the short string of a dual completed well. If tested successfully, low cost screenless completion technology would re-define sand control completion strategies in this area.

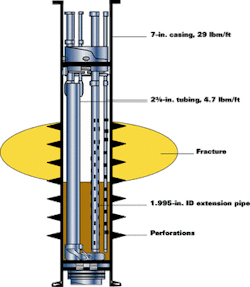

One of the upper zones of Giovanna No. 6, pool 10, was selected as the candidate zone for testing the screenless completion. The well was completed originally as a 2 3/8-in. dual string completion and put on production in December 1992. However, within two years, it had sanded out completely and was shut in at the end of 1994.

null

At Giovanna and other analogous fields, fracturing for sand control must:

- Bypass any formation damage

- Create a highly conductive path to economically deplete the well

- Control sand and fines production by connecting the sand streaks with a single, wide fracture having effective proppant flowback control.

For this well's screenless completion, the need for each step, perforating, consolidation, and fracturing with proppant-flowback control was reviewed individually. In this case, since the well had already been perforated during its initial completion and had a slotted extension pipe across the target interval, a new optimized perforating strategy could not be used in the re-completion. In addition, the low formation permeability and resulting in low zonal injection rates prohibited the use of conventional resins for formation consolidation, with or without subsequent fracturing. Therefore, the options that remained included a cleanout operation to remove the well's sand fill from the upper part of the tubing and between it and the casing, followed by a TSO fracture treatment that included provisions for proppant-flowback control.

Proppants, fracture fluids, and proppant flowback control methods were evaluated to select those most suited for this field application. The zone's relatively low closure stress environment (3,000 psi) simplified proppant selection from an economic standpoint. However, the choice of proppant size was more difficult because of the conflicting requirements.

To maximize fracture conductivity, the largest proppant size was required. To minimize formation particle invasion in the proppant pack, the situation was reversed, with smaller proppant sizes needed. Consequently, a 40/60 US mesh proppant size was selected, which would control formation sand production but not fines invasion in a standard gravel pack, as evident by the many plugged openhole gravel packs in the Giovanna field. However, it was determined that the fracture itself would decrease the likelihood of fines transport by significantly decreasing the pressure drawdown and the gas flowing velocity in the formation during production.

Fluids viscosified with hydroxyethylcellulose (HEC), and then filtered and sheared, had been used traditionally for frac and packs in similar Adriatic Sea formations. However, in low permeability formations, experience had shown that HEC fluids did not create the desired TSO fractures that had the conductivities and geometries (lengths and widths) needed for drainage and sand control. In addition, guar-based polymer fluids historically had not been successful in achieving fracture objectives in the low-to-moderate permeability formations of this area.

After comprehensive fracturing studies and simulations, a viscoelastic (VES) surfactant-based fluid was selected as optimum for meeting TSO fracture objectives at Giovanna. The VES fluid consistently demonstrated good proppant suspension capabilities at low apparent viscosities. By minimizing the fracturing fluid viscosity and optimizing fluid leak-off (by adding alcohol to the fluid system), the short and wide fracture needed for Giovanna's pool 10 formation was achievable.

Prior to fracturing, a coiled tubing (CT) cleanout was performed to remove the sand fill both inside the perforated extension pipe and between it and the casing. A sand plug was set with the top of the sand at 5,754 ft, leaving 39 ft of perforations open for fracturing. For the fracturing operation, all slurry stages were pre-mixed in batch tanks equipped with independently controlled paddles and recirculating centrifugal pumps.

The VES fluid was added directly into the tanks at a 0.625% concentration, along with 1% permanent clay stabilizer and 10% pure alcohol, to limit base surfactant adsorption onto clay platelets. Since the gas-bearing formation was under-pressured, a mutual solvent was added to the potassium chloride brine fluid to accelerate fracture cleanup when performing the step-rate test. Slurry pump circulating continued while the proppant was added to the tanks, but stopped with the PropNET fiber additions (for proppant flowback control), when agitating action was limited to just paddle mixing.

The job was pumped as planned, with increasing net pressure monitored to ensure that a mature, wide TSO fracture was created. A CT cleanup was then performed and the well put on production. The 39-ft zone produced gas with no formation sand, fines, proppant, or fibers for 2 1/2 months at more than twice the initial completion gas rate and flowing pressure. Based on this successful pool 10 screenless re-completion job, the zone was shut in for a major workover program on the well.

Expanding screenless completion use

The Giovanna No. 6 success also was the catalyst to expand the program to other fields in the area. At the Annalisa field, a new Eni Agip Adriatic Sea development, a screenless completion was implemented in a secondary zone that was to be completed via the short string. If not for this new screenless completion technology, this zone would not have been completed and produced.

While initial production results were encouraging, achieving attractive gas rates, sand production did result before the zone was shut in and the primary zone opened for production. It turns out that an initiated TSO fracture did not mature completely because of the lack of pre-mixed fluids, highlighting the importance of continuous onsite blending capabilities. Shortly after, additional treatments were planned back at Giovanna.

Two short string treatments on Giovanna No. 20 were performed using programmable blending equipment with good operational success. However, their layers have not been produced because other layers were targeted for depletion beforehand.

Through these experiences, screenless completion technology is now recognized as an enabler for well scenarios once thought impossible to re-complete. For example, the enabling technology has allowed a challenging rehabilitation to be considered: shut-in wells having failed screens. In this area, Giovanna No. 14 was the first screenless completion candidate that contained screens. Difficult well conditions, sand layer compaction, and long interval sections presented operational challenges. The well's plugged screen situated across a 30-ft re-perforated interval allowed CT access for just the first 12 ft. Consequently, the placed TSO fracture did not cover all of the perforations, resulting in fines migration. Another screenless completion design is scheduled for the Giovanna No. 16 well to complete unproduced sands via a dedicated perforation and fracture treatment. In summary, while some projects were considered a complete success, others having mixed results (from operational rather than technical limitations) provided valuable lessons regarding this emerging technology in future implementations of this novel screenless completion approach.

Future plans

Several screenless completions are planned soon in other fields, where the dilemma facing the completion teams is that the remaining gas reserves within the targeted layers are insufficient to justify the expense of full rig operations. However, the dual completed wells utilize a sliding side door (SSD) in one or more perforated intervals within their short or long production strings. Prior to performing the planned screenless completions, a yard test recently was undertaken to confirm the feasibility of fracturing through SSDs. The test assessed potential surface erosion effects and the pressure integrity of the valve after pumping through significant amounts of proppant.

The pumping test was performed in four individual but sequential stages, with pressure tests and visual inspections conducted after every stage.

After the tests were completed, the SSD valve pressure tested to 3,000 psi, and only minor superficial erosion effects were noted, verifying that a large quantity of proppant-laden fluid could be pumped through a SSD valve without jeopardizing pressure integrity or causing significant erosion.

Summary

The screenless completion is not meant to replace conventional sand control operations using mechanical screens, but is intended to serve as an attractive alternative sand control technique in applicable situations. Candidates for the screenless completion include wells having geometries that would make screen installation logistically difficult, undesired, or even impossible. Other candidates might be re-completion projects whose marginal reserve estimates economically prohibit a rig-based workover. The case histories illustrated that candidate selection was as important as the pre-completion planning and execution of the screenless completion itself.

References Pitoni, E.; Devia, F.; James, S.; and Heitmann, N.: "Screenless completions: Cost-effective sand control in the Adriatic Sea," SPE 58787.Pitoni, E.; Burrafato, G.; Devia, F.; and Heitmann, N.: "Polymer-free fracturing fluid revives shut-in well," World Oil, September 1999, pp. 77-82.

null