WELLBORE DESIGN: How long bits improve wellbore micro-tortuosity in ERD operations

Tortuosity was recognized recently as one of the critical factors in extended reach well operations. The effects include high torque and drag, poor hole cleaning, drillstring buckling, and loss of available drilled depth, among other negative conditions.

Conventional wisdom has always held steerable motors while attempting to correct the actual well trajectory back to the planned trajectory most often generate that tortuosity. However, in the early days of drilling in the mid-continent area of the US, drillers observed a problem with running tubulars into wells.

A vertical well drilled with a 12-1/4-in. bit would not drift 12-1/4 in. This led Lubinski (crooked hole described in the early 1950s) to develop a formula for determining the minimum drift size for a hole drilled with a given collar and bit combination (or the reverse). This became known as the "crooked hole country" formula.

Thus, there was early recognition of the potential for problems due to the fact that the wellbore was not straight. This recognition predated the first use of steerable motors by some 30 years. Today, several types of drilling tools, including those developed by Halliburton Energy Services' Sperry-Sun, are targeted at achieving reduced hole tortuosity as measured by survey data, with a view to reducing torque and drag.

Obvious examples are adjustable gauge stabilizers and adjustable gauge motors, and more recently, rotary steerable systems. In parallel, it is commonly suggested that bent-housing steerable motors increase tortuosity as measured by survey data by mixing high dogleg sliding footage and low dogleg rotating footage. In brief:

- Low dogleg = low torque = "good."

- High dogleg = high torque = "bad."

Recent evidence suggests that any torque and drag benefits derived from reducing dogleg as measured by survey data (macro-tortuosity) are likely to be completely overwhelmed by the torque and drag generated by poor wellbore quality (micro-tortuosity).

Long gauge bits

In the last two years, over 200 wellbore sections have been drilled using long gauge bits, primarily in pursuit of drilling improvements broadly encompassed by the term "hole quality." Most of these bits have been run on steerable motors and some on rotary steerable systems.

Modeling, measuring, and comparing torque and drag values for sections drilled with long gauge bits, and with short gauge bits, immediately showed two surprising results:

- No dramatic difference between the resulting torque and drag values for steerable motors, versus rotary steerables when both use similar bits.

- A significant difference between torque and drag values for long gauge bit runs, versus short gauge bit runs, regardless of the method used to drive them.

The use of long gauge bits also provides an improvement in activities that benefit from improved hole quality or reduced micro-tortuosity. These include hole cleaning, logging operations, resultant log quality, casing runs, and cementing operations.

Quantifying these differences by "back-calculating" the friction factors commonly used in the torque and drag model shows a general trend. The friction factors that provide accurate results for long gauge bits are much lower than the values necessary for obtaining accurate results when using short gauge bits. Coupled with the observable field results, this suggests that attention to hole quality is likely to have a far greater effect on well design limits, particularly in extended reach drilling, than will minute attention to matching directional survey results to the ideal well proposal.

Thus, it is believed that micro-tortuosity is far more important than the commonly known "tortuosity" in determining the resulting torque and drag and overall wellbore quality. Also, micro-tortuosity is highly dependent on the bit, and field results support this contention.

Micro-tortuosity solution

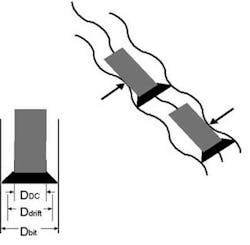

The ability of any bit to move off the centerline of the wellbore is determined by the gauge length on the bit, the amount of side cutting structure on the bit, and the stabilization of the bit and bottomhole assembly (BHA). Other factors may play a role in reducing the tendency to move off center, such as anti-whirl feature, but these factors address symptoms rather than causes.

The concept of preventing side-cutting to improve hole quality is not new, as machinists have taken advantage of it for years. A conventional twist drill for drilling through metal is furnished with a cutting structure that cuts only in the direction of the tool's long axis, and the spiral flutes serve only to stabilize the cutting structure, and "burnish" the sides of the hole.

Until the flutes begin to stabilize the cutting structure, the drill will tend to precess in the same direction as drill rotation. This can readily be observed using a domestic electric drill and explains why the hole being drilled is often triangular until the stabilizing flutes begin to control this movement. If they did not exist, the drill would continue to precess, and the resulting hole would be triangular in section, following a helical path.

There is now abundant evidence that hole spiraling exists, whether this evidence is anecdotal, visual (from imaging tools), by inductive reasoning from logs with an otherwise inexplicable periodic variation, or from tools with an otherwise inexplicable wear pattern. There is also abundant evidence that long gauge bits minimize or more often eliminate hole spiraling.

Since the drilling industry depends on steering, if "long gauge bits do not steer," then this piece of information is interesting, but has no practical application. Once it is discovered that long gauge bits can be made to steer, initially on specially designed motors, and subsequently on point-the-bit rotary steerable tools, then the information is worth re-examining.

Bit design

When this thinking was applied to oilfield bit design, the results were surprising. Straighter holes have resulted in friction factors that defy conventional expectations. Bit life has been extended greatly. Circulation time as a percent of below-rotary hours was reduced to 10-12% on average, demonstrating the efficiency with which the cuttings are being circulated out of the well.

Short trips were reduced or eliminated. Log quality and ease of running logging tools was improved. Cement job success rate was nearly 100%, with cement bond logs to demonstrate the high quality of the job. MWD and LWD (measurement-while-drilling and logging-while-drill-ing) failures were reduced due to the drastic reduction in downhole vibration. Lost-in-hole risk was reduced. Entire hole intervals were drilled in record times repeatedly.

Of note is that the drilling system employed required changes to the bit design as well as changes to the positive displacement mud motor design. While these benefits apply to the vast majority of wells being drilled today, the reduction in friction delivered by this new system is of particular value for pushing the extended reach envelope even further than previously thought possible. Micro-tortuosity affects almost every aspect of drilling and completing a well:

- Bit life and MWD/LWD tool reliability: Bits that were designed to cut away the side of the hole as well as the hole in front of it tend to drill a spiral hole with bit vibrations, resulting in shorter bit life. The same vibration that destroys the bit also travels up the drill string and can lead to a premature MWD/LWD failure.

- Hole cleaning: Due to the rugosity of the spiral wellbore, cuttings will travel a tortuous path and will encounter a trough every 2-10 ft (depending on the pitch of the spiral). When using the new drilling system with the long gauge bit, entire intervals have been drilled without short trips and with greatly reduced circulating hours.

- Rate of penetration: Stabilizers will tend to hang up in a spiral hole, especially in a non-rotating (sliding) mode. This mechanism explains the reduction in sliding rates of penetration (ROP) relative to rotating ROP that is generally recognized as a universal phenomenon.

- Stabilizer wear: Stabilizer hang up in spiral holes would also result in the excessive wear on the leading and trailing edge of stabilizers that has been observed on numerous wells.

- Torque and drag: The torque and drag in the wellbore often determine the success of drilling extended reach or horizontal wells.

- Logging tool response: Spiraled boreholes have long plagued wireline and LWD service companies and have led to totally ambiguous responses from resistivity, density, neutron, and other logging sensors.

- Cementing: The spiral borehole described previously is equivalent to a continuous thread in the well. There are no cased hole logging tools in existence today that can measure minimum cement thickness that wraps around the casing in a cement job, so it has escaped detection so far.

- Gravel packing: In gravel packing wells, and especially inclined wells, a good distribution of gravel over the entire gravel pack interval is the design goal. A gravel pack screen that has been run in a spiral wellbore faces the same annular clearance issues described above. The tortuous path the gravel is required to travel may well be the root cause of many of the early sand-out problems that have been experienced.

Conclusions

Tortuosity has been redefined as having two components: macro-tortuosity and micro-tortuosity. Macro-tortuosity can be detected by examining survey results. Micro-tortuosity is a smaller scale dogleg that will not show up in MWD survey data. Advanced wireline survey techniques or MWD caliper tools can detect it.

Micro-tortuosity commonly exists in the form of hole spiraling. Analysis of hundreds of wells indicates that micro-tortuosity exists in many of the wells being drilled today. Friction factors back-calculated in the torque and drag model are used to quantify the micro-tortuosity. Data indicates that micro-tortuosity is an important component in total tortuosity.

Many factors contribute to hole spiraling or micro-tortuosity, but the most significant issue is the bit design. There is abundant evidence that long gauge bits eliminate hole spiraling. To exploit the benefits of long gauge bits, a new motor system has been designed to be able to steer the long gauge bit. The same benefits are available from "point-the-bit" rotary steerable tools.

Field data using the new drilling system have shown a much lower friction factor compared to that from any existing drilling system. This suggests that only by removing micro-tortuosity, can one drill a truly smooth wellbore, regardless of the technology employed to steer the well.

Eliminating or reducing spiraling quantifiably improves nearly every facet of the drilling operation. None of these improvements can be realized by a likewise reduction in steering-related macro-tortuosity. Micro-tortuosity should be routinely considered in torque and drag modeling exercises. Until then, the industry will make decisions on field development that are based on extended-reach-drilling limits susceptible to dramatic improvement at little cost.

References

Banks, S., Hogg, T., Thorogood, J., "Increasing Extended-Reach Capabilities Through Wellbore Profile Optimization," IADC/SPE #23850. 1992 IADC/SPE Drilling Conference, New Orleans, Louisiana.

Payne, M., Abbassian, F. "Advanced Torque and Drag Considerations in Extended-Reach Wells" IADC/SPE #35102, 1996 IADC/SPE Drilling Conference, New Orleans, Louisiana.

Guild, G., Hill, T., Summers, M. "Designing and Drilling Extended Reach Wells," Petroleum Engineer International, January 1995.

MacDonald, G., Lubinski, A. "Straight-Hole Drilling in Crooked-Hole Country," Drilling and Production Practice, API 1951.

Woods, H., Lubinski, A. "How to Determine Best Hole And Drill-Collar Size," The Oil and Gas Journal, June 7, 1954.

Gaynor, T., Chen, D., Maranuk, C., Pruitt, J. "An Improved Steerable System: Working Principles, Modeling, and Testing," SPE #63248, 2000 SPE Annual Technical Conference and Exhibition, Dallas, Texas.

Dykstra, M., Chen, D., Warren, T., Zannoni, S. "Experimental Evaluations of Drill Bit and Drill String Dynamics," SPE #28323, 1994 SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana.

Editor's Note: This is an updated version of SPE/IADC #67818.