DRILLING RIG ECONOMICS: Large Caspian Sea jackup required float-in, plus local fabrication

The area around and under the Caspian Sea contains about 10% of the earth's potential crude oil reserves, according to the latest estimates. That equates to about 200 billion bbl, valued at about $4 trillion. With these tremendous reserves as incentive, Transocean Sedco Forex reached the decision to build the first Western-specification jackup exclusively designed for use in the region.

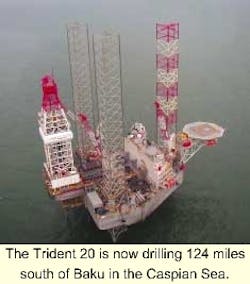

"As one of the new frontiers for crude oil exploration, the Caspian Sea appeared to us three years ago as an attractive offshore drilling market for the long term if we could secure a cost-effective and efficient jackup rig that could also meet our safety and quality-of-life objectives for the rig's crew," Jean P. Cahuzac, Executive Vice President and President, Europe, Middle East and Africa for Transocean Sedco Forex Inc. explained. The rig that came into being as a result of that decision is the Trident 20.

Regional challenges

Transocean Sedco Forex designed the Trident 20 specifically for operation in the Caspian Sea, where temperature and soil conditions can present significant challenges. "The Trident 20 can work in up to 350 ft of water, and it has larger spud cans to manage the risk of punch-through on the soft Caspian Sea floor. It also provides state-of-the-art drilling capabilities, a large deckload since few supply boats are available, and can operate in -10° C and in a controlled-discharge mode," Cahuzac said.

Although the Trident 20 design incorporates some interesting specifications, the rig is probably of interest as much for its design as for the process that led to its construction. Complex international logistics posed a considerable challenge to the project.

Surrounded by Iran, Azerbaijan, Kazakhstan, and Turkmenistan, the Caspian Sea is landlocked. The only way Transocean Sedco Forex could get a jackup into the sea was to build it there. Clearly, the construction of a new shipyard in Baku, Azerbaijan, was an essential milestone that had to be reached before construction could begin on this rig. The company began negotiations with Keppel FELS (KFELS) in Singapore.

Local fabrication

In 1996, when plans were being laid for building the jackup, it was evident there was a need for a shipyard in Baku that could handle the task of building the rig. Transocean Sedco Forex approached the Keppel FELS shipyard in Singapore and negotiated for a KFELS Mod V jackup. The agreement required that the rig be built partially in Singapore and partially in Baku.

Because the Azerbaijan shipyard would be new, the determination was made for technically difficult pieces to be built in Singapore. These pieces included spud cans, three 500-ft leg sections, the cantilever, the drill floor, jack cases, lower guides, and the leg-jacking mechanism.

As construction of the more complex parts began in Singapore, KFELS started building what would become the Caspian Shipyard Company in Baku. The company also determined to man the shipyard with local laborers. Although jackups and semisubmersibles had been built in Vyborg and assembled in Astrakhan in the Soviet era, nothing like the Trident 20 had ever been constructed in the area. According to Cahuzac, "Transocean Sedco Forex has been very pleased with the quality of the local personnel."

While work at both shipyards progressed, plans for transportation had to be put in place. In the end, pieces had to be shipped 6,377 miles across the Bay of Bengal, through the Suez Canal, across the Mediterranean and Marmara seas, past Istanbul, through the Bosporus Straits into the Sea of Azov, and into Mariupol in the Ukraine.

At Mariupol, the pieces were offloaded onto river barges for the second leg of the journey, which would cover another 980 miles. The barges passed through the Don-Volga Canal System through locks and reservoirs en route to Kalach NaDonu, where they entered the River Volga system and eventually moved by river to Astrakhan on the Caspian Sea, and finally on to Baku. Three shipments were made along this route before all of the pieces were finally assembled in Baku.

Despite formidable challenges, the Trident 20 was completed in Septem-ber as a result of what Cahuzac refers to as "close cooperation with our customers in Rig Club 2 (a consortium made up of Total Fina Elf, ExxonMobil, Agip, and JAOC of Japan), SOCAR (the State Oil Company of the Azerbai-jan Republic) and the KFELS shipyards, both in Singapore and in the new Baku facility."