Mobility steering helps place injectors

Peter M. Neumann

Abd Khair B. Abdul Aziz

Saudi Aramco

Vikas Agrawal

Schlumberger

The use of formation-pressure-while-drilling (FPWD) to optimize well placement above a heavy oil zone has become a very useful procedure for Saudi Aramco.

One of Saudi Arabia’s giant carbonate oilfields is in a northwest to southeast trending anticlinal structure. Most of the field is offshore and is accessed by land-based directional wells with extended lateral legs. Production opportunities exist in the presence of formation heterogeneity and a less mobile to immobile heavy oil layer between the aquifer (that would normally drive production) and the zones above it. The heavy crude layer is viscous and affects the ability of the natural water drive to energize the flow of oil to the surface.

The reservoir also contains very low permeability randomly distributed baffle zones of mud-lean packstone, and variable shallow marine carbonate facies consisting of carbonate grainstones, some with calcite cementation and minor dolomitization. The optimum injection zones are difficult to define, but using pressure-while-drilling and nuclear magnetic resonance (NMR) can improve injection location. Porosity is not the issue for the field; permeability and mobility are the driving factors to a successful reservoir penetration. Mobility is defined as the ratio of formation permeability (in md) to fluid viscosity (in cp).

Energizing flow

Recognizing that the heavy crude layer prevents the reservoir aquifer from providing sufficient natural drive, a pressure maintenance involving closely spaced power water injectors was launched. The reservoir consists of an upper Zone A, a lower Zone B, with a low permeability zone (LPZ) in between. The injector wells were to be placed in Zone B as close as possible to the producible oil/heavy oil interface, called the oil/heavy oil contact (OHOC) in an attempt to provide a bottom-up sweep of the lighter crude toward the producing wells.

If LWD resistivity, porosity, and hydrocarbon saturation calculations are essentially the same in both the heavy oil and lighter oil zones, how could the wells be placed to optimize injection? Compounding the question is the overlying mud-lean packstone that had moldic (oolitic-like) porosity between 25% and 30% but little permeability.

The team first analyzed each major reservoir layer to determine its identifying characteristics. The overlying low permeability packstone layer (LPZ) was described as:

- Supercharged formation pressures while drilling

- Low mobilities from FPWD measurements

- General decrease in average gamma ray as seen in some flanking wells

- Very low resistivity in flanking wells near the reservoir boundary

- High water saturation in flanking wells near the reservoir boundary.

Below the LPZ, in Zone B, good permeability was expected with variable fluid mobility until the heavy oil was reached. Fluid mobility would drop dramatically below that point. It was critical to identify the low permeability and the heavy oil zones while drilling in order to steer into the more injectable rock.

A solution surfaces

The team concluded that a FPWD device would be the best real-time solution to identify facies changes and to measure fluid mobility in the injection zone.

Well design caused additional complications. The well plan called for an 8 1/2-in. build section to be drilled and landed in the top of Zone B, followed by a 6 1/8-in lateral section completed as a power water injector.

FPWD logs taken in the lateral section (Zone B) illustrate how pressure and mobility data (green dots) aid steering decisions. The lack of character of the density/neutron curves (upper track) implies that making steering decisions using these logs alone would have been impractical.

Traditional heavy oil detection methods, with the exception of drill cutting analysis (mud logging), generally occur after the well has been drilled. Mud logging and pyrolysis can indicate heavy oil, but are inconclusive for permeability, pore throat plugging, and near wellbore mobility in a heavy oil transition zone. Unless emerging LWD NMR technology is available, identification of the low permeability/low mobility can be done with FPWD technology. FPWD provides the sandface pressure and near wellbore mobility in real time. Low permeability or heavy oil zones utilizing LWD formation testers previously resulted in one or more of the following:

- Dry/tight tests

- Supercharged pressures and low mobilities

- Lost seals due to very little or no mud cake formation in heavy oil or low permeability zones.

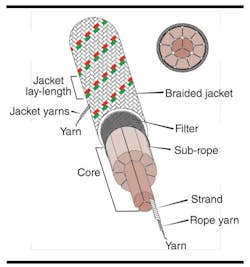

FPWD tools can run as an integral part of any LWD bottomhole assembly. The Schlumberger StethoScope 675 FPWD tool was selected for the 8 ½-in. landing section, and StethoScope 475 slimhole FPWD tool was selected for the 6 1/8-in. lateral section, in addition to the LWD services. Back-up pistons in these tools push the tool’s probe against the borehole wall. This ensures that the tool does not have to be oriented. The testing sequence is intelligent and automatic, making pressure testing highly efficient.

A built in safety feature of these FPWD tools ensures that the pistons do not deploy when the drillstring is moving (either rotating or sliding). If the pistons experience damage, they are field-replaceable. A series of variable-volume pre-tests can be executed for each setting with pressure data transmitted uphole in real time.

Mobility steering in action

The team began systematically to collect pressure and mobility data at regular intervals from the time the BHA entered Zone A. The FPWD tool can take a series of pre-tests each time it sets, several investigative tests, and a final test. Pressure data from the StethoScope tool is available at the surface every three seconds in real time, which gives a reasonable characterization of both drawdown and build-up pressure transient profiles. Quality control parameters such as slope of the pressure curve and pressure variance can be observed readily in the available data.

The quality control parameters were used to determine if the pressure transient had stabilized, as well as the signal-to-noise ratio during each measurement. The data points went to Saudi Aramco’s geosteering and project team after passing quality control checks. The teams were in constant communication and operated around the clock to make timely steering decisions for optimized well placement.

A total of 48 pressure tests were taken with a seal efficiency of 98% while drilling the landing section through Zone A and LPZ. The acquired pressure and mobility profiles clearly indicated that the 8 ½-in. well path had exited Zone A and began drilling through the LPZ. The pressure readings followed a consistent gradient line and mobilities regularly exceeded 10 md/cp in Zone A. The pressures started to deviate from the gradient line and mobilities began to decline, indicating a gradual transition into the LPZ after drilling an additional 700 ft (213 m).

Supercharging increased and mobility decreased sharply, as predicted, once the LPZ was entered. The supercharging effect decreased and mobility started to rise as the borehole neared the top of Zone B. The decision was made to land the build section in the LPZ for well-geometry considerations. The 6 1/8-in. section then was drilled to ensure enough space to steer the well and to maintain the well path above the oil/heavy oil contact.

The objectives become two-fold after the bit enters Zone B:

- Avoid the heavy oil zone

- Steer the lateral through the highest mobility reservoir.

A total of 63 pressure tests were taken with the FPWD tool with a 100% seal success rate while drilling the 6 1/8-in. extended reach lateral. Due to the availability of real-time data, three well path changes were predicated on fluid measurements. In total, 5,357 ft (1,633 m) of the lateral was MobilitySteered, 70% of which was placed in high mobility zones.

The combination of real-time FPWD and other LWD data was critical to determine the landing point for the build section, and to enable well placement in high mobility reservoir sections. A similar approach is planned for subsequent wells placed in Zone B for the power water injector project. •

References

Neumann, P. M, Salem, K. M., Tobert, G. P., Seifert, D. J., Dossary, S. M., Khaldi, N. A., Shokeir, R. M.: "Formation Pressure While Drilling Utilized for Geosteering" SPE paper 110940, 2007 SPE Saudi Arabia Technical Symposium, Dhahran, Saudi Arabia, May 7-8, 2007

Douglas J. Seifert, Peter M. Neumann, Mamdouh N. Al-Nasser, Saleh M. Al-Dossari; Saudi Aramco, A. Patrick Hibler; Schlumberger "Optimizing Horizontal Well Placement Using Formation Pressure While Drilling Measurements," SPWLA 49th Annual Logging Symposium in Edinburgh, Scotland, May 25-28, 2008.