DRILLING & PRODUCTION

Kevin McMillin

Houston

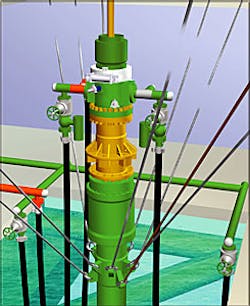

Operational procedures of the RiserCaptrademark are similar to those used for conventional surface stack wear bushing installation and retrieval.

Borehole world records continue to fall

Advances in the oil and gas borehole technology have taken place at unprecedented rates for the past 4-5 years. Four new drilling world records, one for "any mud" type and three for water-based mud, have been set recently. They are:- Longest horizontal section with water and "any" mud type, at 20,069 ft.

- Deepest well with water based mud, at 29,631 ft measured depth.

- Longest horizontal displacement with water based mud, at 23,265 ft.

Creative directional tool applications used in the final section of the 8 3/4-in. and 6-in. hole sections included straight (no preset bend) conventional motors with an adjustable stabilizer below and above the motor, in the respective hole sizes. All stabilizers were undergage with the adjustable stabilizer controlling directional response.

Adjustable stabilizers have been used in rotary assemblies for the past decade to give added directional control capability. In horizontal extended reach well applications, reducing wellbore tortuosity directly reduces drillstring friction and extends total depth capability. In these world records, directional measurements close to the bit, adjustable stabilizers, and conventional steerable motors made subtle hole trajectory corrections possible. These smaller and more frequent corrections reduced overall wellbore tortuosity, yielding greater total depth capability.

Sperry Sun, a division of Halliburton Energy Services, contributed in the achievement of these records in the Danish North Sea well, MFF-19C of the Dan Field.

Deepwater pore pressure models

Drilling in great water depths raises many technical questions, which in turn require more thorough planning. Predictive tools are used to help in project engineering design. Formation pressure estimation and determination is a key part of this process.Conventional formation pressure estimation has been more of a "guess-timation" technique, subject to operator experience and knowledge, and definitely after the fact. Some regions of the world provided enough overall drilling coverage, experience, and data to yield empirically derived overlays for estimation purposes.

These are interpretive, and not predictive, while-drilling techniques. Service companies have improved predictive techniques to better estimate formation pressure horizons with seismic information, and update pore pressure estimates in real time while drilling.

Computer and software advances have made it possible for older, manually adjusted overlays to be controlled and continually monitored by software. This automation frees up engineers and operators to focus on other while-drilling tasks. The downside is that too much dependence on software can be dangerous. A complete understanding of the mechanisms for abnormal formation pressures in your respective drilling regions is necessary.

For example, the existing US Gulf of Mexico overlay models, both manual transparency and software, are empirically derived from data collected in a continuous depositional basin. In areas of "planktonic" deposition, usually deeper waters, these models may be invalid simply by method of deposition. Formation pressure mechanisms most likely vary for the producing basins around the world. Use of "regionally derived" models could lead to erroneous formation pressure estimations.

New deepwater while-drilling pressure control products

Underbalanced drilling (UBD) in deepwater has taken another step toward becoming a reality. Some jackup platform drilling projects in the North Sea have already successfully completed UBD projects. Deepwater applications using semisubmersible drilling units are considered still in the "idea" phase, with certain regulatory, procedural, and safety issues to be worked out. However, the "idea" is becoming a reality with the recent introduction of new rotating control head systems for deepwater risers.These systems can function as a passive part of a conventional slip joint/diverter system, or replace the Regan Diverter and slip joint with the use of a running tool. The systems are conveyed in a manner similar to wear bushing installation and removal procedures. No disassembly or re-assembly of the riser is necessary.

Benefits realized from this technology are a pressurized mud return system, elimination of the bell nipple assembly, greater reliability than the slip-joint system, and compatibility with UBD and gas-liquid mud systems.

Also, application in environmentally sensitive offshore areas is a key feature. Spill containment problems are easily dealt with. Conventional well control requires closing annular preventers and assessing drillpipe and annular pressure situations. With constant, while-drilling pressure control capability on the drillpipe and annulus, lower decision making-to-solution implementation time, during well control situations can be realized.

Riserless drilling is also a step closer to availability as a viable option for drilling in ultra-deepwater. The development of subsea rotating control head technology is adding another piece to the deepwater puzzle. Virtual Risertrademark technology uses currently available rotating control head (RCH) products to provide pressure control of shallow, abnormal formation pressures during riserless drilling operations. Also, applications in shallow water flow are being developed.

Williams Tool Company, in a joint industry project with Mobil, Amerada Hess, BP, ADS, and Petrobras (the organizer), are marketing the RiserCaptrademark technology for future use in deepwater applications. Virtual Risertrademark technologies continue to be developed and marketed by Williams Tool Company.

Multi-part series to focus on PWD

Aggressive directional drilling objectives have focused attention on drilling mechanics and heightened interest in pressure while drilling (PWD) measurements. Offshore magazine will publish a multi-part series in the coming months on the use and applications of PWD measurement. Sperry-Sun, a Halliburton Company, has identified several new applications of drilling mechanics measurement. These include detection and monitoring of shallow water flows, kicks and well control, loss/gain balooning, improved leak-off tests, and basic drilling practices such as tripping speeds, reaming, and circulation issues.Copyright 1999 Oil & Gas Journal. All Rights Reserved.