Coping with drilling surprises

Managing pressure with real-time borehole measurement

Judy Maksoud

International Editor

Drilling surprises cost money, and those costs can be enormous in a challenging drilling environment. Offshore Nova Scotia, one of the most challenging environments in the world, one of the region's biggest drilling challenges is cont-rolling pore pressure.

"Wells in this region routinely struggle to keep pore pressure integrity," according to Glen Sansom, Schlumberger's general manager for Atlantic and Eastern Canada. "Six-figure numbers have been lost as a result of pore pressure losses."

In a frontier where deepwater wells cost $75-$100 million, operators want to find a way to manage this problem.

Quite possibly, a team of engineers at Schlumberger's office in Atlantic Canada has found an answer.

Regional issues

Most of the supermajors have drilled exploration wells off Nova Scotia in the last five years, and all of them have encountered problems with pore pressure. Often, the result of a drilling surprise is that the well is not able to evaluate the primary target.

Dave Collyer, a vice president at Shell Canada Ltd., addressed this problem at the North American Natural Gas Conference held in Calgary, Alberta, in March 2004. Collyer cited high pressure as one of the problems Shell encountered at a deepwater exploratory well being drilled near Sable Island. Ocean Rig's Eirik Raude had made no progress toward TD in weeks on the Weymouth well, according to Collyer, who expected drilling to take another month.

High pressure continues to be an enormous challenge.

Determining a reliable pore pressure and fracture gradient profile is important when planning any well, but having a plan may not eliminate all drilling surprises. That is why updating predictions while drilling is so important, particularly in an area that is notorious for its high-pressure drilling environment.

The obvious solution is to manage pore pressure while drilling, but that is more easily said than done. The primary reason is that it is difficult to accurately determine pore pressure in real time.

In fact, until recently, exact measurements could not be taken in real time. The standard approach for determining pore pressure has been to take measurements on formation pressures via wireline to get measurements while drilling the well. Now, Schlumberger has proposed a different approach.

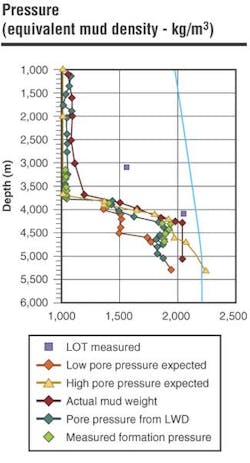

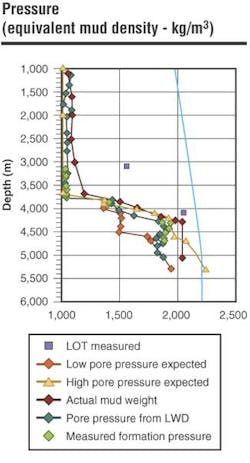

Engineers are now able to take resistivity and acoustic measurements with LWD and use them to calculate pore pressure with a very high degree of accuracy. Although the use of LWD measurements for this purpose is not all that new, the modeling process that translates those measurements into accurate pore pressures is very new.

Pinning down the numbers

According to Barry Parsons, Schlumberger drilling and measurements operations manager for Atlantic and Eastern Canada, the critical first step toward optimized drilling is quantifying the pore pressure.

"Over the past few years, we've made a lot of progress trying to find ways to determine pore pressure," Parsons said. According to Parsons, the team has found a way to calculate the pore pressure. This has been particularly challenging in Nova Scotia, as the pore pressure environment includes a complex mix of pressure mechanisms, commonly referred to as Type I and Type II over-pressure, or loading and unloading.

"We now know for the first time how to convert resistivity and acoustic measurements into a pore pressure number with a high degree of certainty," Parsons said.

null

"The real trick with the high-pressure/ high-temperature (HP/HT) wells off Nova Scotia is that the technology and equipment we use to take measurements isn't all that new, fancy, or creative," Parsons said.

"In almost every over-pressure well we've been involved with in Nova Scotia, the post-mortem analyses of the pressure indicate it was a lot greater and happened at much shallower depths than anticipated," Parsons said.

"What we didn't have until recently is a structured system that tells us what to do when we make observations that do not agree with our plan. Now, we can take the data, pump it back into the model, and generate a new plan," Parsons said. Schlumberger expects this new capability to improve drilling operations.

The ability to change the plan quickly to accommodate changes is critical. It can make the difference between taking the well to TD or not. So Schlumberger creates contingency plans with the operator on what to use.

The primary concern now is to engage in a cooperative effort with operators to do modeling and planning far ahead of drilling. Because Schlumberger is involved in some high-pressure drilling work off Nova Scotia this year, there should soon be an opportunity to test the plan.