Intelligent completions boost production from Caspian Sea

Yury Korchagin field sees several technology 'firsts'

Mikhail Golenkin

LUKOIL-Nizhnevolzhskneft

Igor Bulygin • Artur Latypov

Schlumberger

Increased reliability and simplicity of downhole tools has significantly expanded the opportunity to run intelligent completions. This is especially true where hardware, including pressure and temperature gauges, remotely operated downhole flow control valves and inflow control devices, provides continuous reservoir monitoring and control to boost field economics through improved recovery and extended production life.

Intelligent completions are especially effective in challenging reservoirs, including those where water and/or gas breakthrough is a risk. Data from gauges enable real-time monitoring of key production parameters, allowing operators to analyze changes in production profiles, productivity index, and reservoir pressure and temperature. Flow control valves (FCV) make it possible to redistribute production from one zone to another to reduce water and gas breakthrough, minimizing the need for costly well interventions.

In a collaborative undertaking, Russian operator LUKOIL-Nizhnevolzhskneft and Schlumberger designed the first four intelligent completions in the Caspian Sea, giving one of the fields a second life. The project involved implementation of multilateral and intelligent completion technologies with real-time drilling and production management. Optimization using intelligent completion software and zone-by-zone cleanup further enhanced field productivity.

The operation marked the first deployment in Russia of the Schlumberger WellWatcher Advisor intelligent completion software, which provided continuous, real-time monitoring and data interpretation. The software minimized the need for intervention, enhanced understanding of reservoir properties without a well test or shut-in, optimized inflow performance, and increased productivity by drawdown and inflow profile balancing.

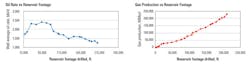

Located on the shelf of the North Caspian Sea, the expansive Yury Korchagin field features a thin oil rim of 10 to 15 m (33 to 49 ft) with an anticline trap, or dome, of impermeable rock overlying permeable reservoir rock. The oil pay is positioned beneath a significant gas cap and above an aquifer. In 2010, LUKOIL-Nizhnevolzhskneft began developing the complex field with a horizontal extended-reach drilling (ERD) campaign from a single platform.

Starting with the first well, however, a number of issues indicated the project faced steep economic challenges. Early gas breakthrough led to high gas/oil ratio (GOR), up to 35,000 standard cubic ft per stock tank barrel (scf/stb), resulting in a sharp decline in oil production. Recovery was 17% below initial estimates from the least-performing formation. Additionally, a limited number of slots on the platform were available to drill additional wells, leaving no options for mitigating the losses.

In considering methods for reviving production, LUKOIL-Nizhnevolzhskneft and Schlumberger devised a unique, multidisciplinary approach to improve recovery in the field using an intelligent completion strategy that involved implementation of real-time monitoring and optimization and multilateral technologies. Schlumberger experts from multidisciplinary teams worked together to meet the customer’s objectives.

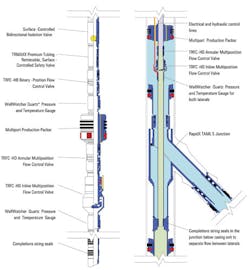

First intelligent completion

In the first intelligent completion in the Caspian region, a multi-zone horizontal well drilled in 2014 involved installation of eight pressure gauges on a single cable. Hydraulic FCVs, each instrumented with pressure and temperature gauges, took measurements from both the annulus and tubing. The horizontal section was divided into four zones, with isolation provided by swell packers. Each zone was equipped with a FCV that successfully controlled inflow as well as annular and tubing pressure and temperature gauges. Each zone could be independently opened and closed using variable choke settings of up to eight positions, with the gauges monitoring pressure drops across each valve. The well is currently the one of the best producers in the Korchagin field.

Wells in the Caspian Sea typically experience gas breakthrough, drops in oil production and escalating gas/oil ratio in the first three months of production. To address those issues, as well as the limited number of available platform slots, the team in 2015 designed two intelligent multilateral completions, also a first for LUKOIL-Nizhnevolzhskneft and Schlumberger in the region. The objective was to reduce the rate of gas breakthrough and delay water breakthrough using real-time drawdown redistribution to respond to changes in production during the life of the wells.

The dual-lateral wells were the first in Russia to be engineered with the pressure-tight TAML 5 junction, which includes a mechanical, continually interlocking rail system that resists internal and external pressure to prevent gas and water at the junction from exiting through the completion. The intelligent completion string was sealed below the junction. In each lateral, ICDs were positioned on intervals isolated by swell packers. Each lateral was monitored and controlled by its own FCV and gauges.

These multi-position valves, installed above the junction and hydraulically controlled from the surface, actively monitored inflows from each lateral to control drawdown. Pressure and temperature gauges enabled real-time tracking of the formation conditions in the drainage area of the laterals. Measurements from the gauges tracked reservoir conditions and estimated flow rates. This data was interpreted to determine reservoir parameters with the help of the intelligent completion software.

Production in the first multilateral well, which consisted of the motherbore and one side track connected by a junction, was achieved with much lower drawdowns than for a single-lateral well. Flow rates exceeded 400 tons of oil per day. GOR and water cut improved when compared to offset wells where gas and water breakthrough had been observed. The rate of water and gas movement markedly slowed, even with the proximity of the gas/oil contact and oil/water contact to the wellbores.

Tripled production

The second multilateral completion was designed with a side track drilled in the existing well and connected to the motherbore, again by a TAML 5 junction. The motherbore, which was drilled in 2013, was retained and continues to produce. The well had previously produced with a high GOR and low flow rates. The side track effectively increased the coverage ratio, or sweep efficiency, and redistributed the drawdown between and along the laterals, with the help of ICDs and FCVs. This resulted in a 75% reduction in GOR while the oil production rate more than tripled compared with previous wells without side tracks.

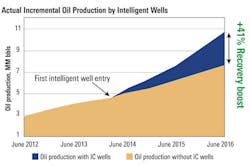

The intelligent multilateral wells demonstrated that drilling an additional leg delivers benefits similar to drilling an additional single-lateral well without the costs of drilling the upper well section. Field production targets for 2015 were achieved, with 740,000 barrels of incremental oil gained from ML wells. For both intelligent multilateral wells, LUKOIL-Nizhnevolzhskneft implemented a lateral-by-lateral cleanup procedure using multi-position FCVs from the surface to close each lateral. Autonomous ICDs installed in each lateral balanced the drawdown and inflow from each in-lateral compartment. This further enhanced efficiency and productivity, keeping the wells online much longer than conventional wells. For Schlumberger, the intelligent TAML 5 wells were the first ever planned and executed with zero NPT.

The fourth intelligent completion was installed on one of the oldest wells in the Korchagin field. In February 2016, a new horizontal wellbore was drilled as a side track and split into three intervals isolated by packers after the motherbore was abandoned. Three FCVs, one for each zone, were installed, along with pressure and temperature gauges in each zone to control inflow.

Based on the effective lateral-by-lateral cleanup protocol used in the previous multilateral wells, LUKOIL-Nizhnevolzhskneft executed the world’s first zone-by-zone intelligent cleanup in the fourth well, with real-time monitoring facilitated by the intelligent completion software. The first zone intersected a fracture so GOR and water cut were high. However, both were completely controlled by the FCV. In the second interval, which was a highly productive oil-pay zone, overall production results were good. The operator determined that without the use of the intelligent completion strategy, the well would have been choked back at surface because of uncontrolled gas breakthrough from the fracture resulting in a reduction in well productivity.

The intelligent completions boosted recovery for the weakest formation in the field by 41% and increased oil production by 3.5 MMbbl. Of the 25 ERD wells in the Korchagin field, the four intelligent wells account for 30% of the total produced oil. Expanding on the success of these initial intelligent multilateral completions, LUKOIL-Nizhnevolzhskneft has adopted the approach for development of new Caspian fields.