Shallow-water capping methodology helps mitigate flammable gas risk

Christopher LeCompte and Alistair Gill, Wild Well Control

Any shallow-water capping methodology has to address a number of factors, but perhaps the most important is the presence of flammable gas on the surface of the ocean. As it pertains to well control events, shallow-water capping depth ranges to approximately 150 m or less with a subsea wellhead system.

A new approach to shallow-water capping involves heavy pre-planning operations as part of the overall approach to capping blowouts. The methodology for well control is divided into three parts: analytical evaluation of the well’s risks including depth and hazard potential; identification of qualified equipment for deploying and capping operations; and application of the analytical data to provide an engineered solution using statistical modeling.

Evaluating risk during pre-planning

In comparatively shallow-water depths, working and deploying subsea equipment can be particularly challenging. A partial list of complications for capping shallow-water well events includes large radius surface boils, and large clouds of dangerous or explosive gas/lower explosive limit (LEL) capable of igniting and creating potential fire hazards at or near the well site.

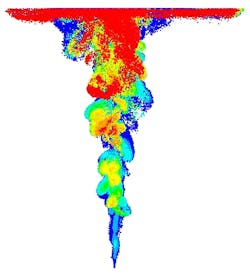

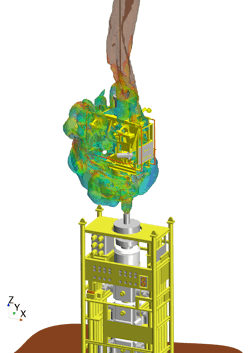

When evaluating the well’s risk, flammable gas must be taken into consideration, as the presence of gas will affect the overall capping operation. A key component of this shallow-water capping method is the creation of computational fluid dynamics (CFD) simulations. These simulations enable engineers to model the dispersion of the hydrocarbons in the ocean as they rise from the seabed to the surface. These simulations determine the radius over which gas breaks out into the atmosphere, the so-called surface boil, and whether or not the gas concentrations are likely to form a flammable cloud.

As the gas rises through the water column, it drags a quantity of seawater with it. Once the gas reaches the sea surface, it disperses into the atmosphere. However, gravity prevents the upwelling seawater from doing the same, and a series of surface waves and a radial outflow develop. These surface waves and the radial outflow impact the capping stack deployment vessel, which must be able to hold its position relative to the well center.

Case study

As part of its pre-planning operations, a client contacted Wild Well to assist with planning for a well in a water depth of approximately 120 m with a potential blowout rate approaching 900 MMscf/d of gas and 40,000 b/d of oil. A subsea plume and gas dispersion analysis was conducted for the given well particulars, and the results showed a 50-m boil at surface with a gas cloud of flammable gas extending 50 m upwind and 1,200 m downwind from the well center. The results of these analyses were used to plan for potential relief well locations and to evaluate equipment for capping stack deployment.

Two different equipment scenarios were developed for capping the well, and Wild Well was able to provide a relief well plan and capping stack deployment plan based upon the expected worst-case surface conditions. These plans were included in the client’s overall emergency response plan submitted to and approved by their regulator so that the drilling project could move forward.

By applying the analysis and output of the modeling software, the characteristics of the shallow-water plume behavior can help estimate the potential gas concentration and surface boil. With this methodology, engineers can identify the equipment needed to safely deploy the capping stack over the center of the blowing well, while accounting for shallow-water capping challenges.

Equipment selection

When determining potential equipment selection, Wild Well prefers to make the choice from vessels of opportunity based on the particular circumstances surrounding the specific well event. Qualified vessels available in the region can include the use of large, “heavy-lift” vessels of barge, shipshape, and semisubmersible type, and some smaller vessels if dictated by the situation.

By incorporating the benefits of dynamic positioning capability into the overall response effort, vessel station keeping can help protect equipment and personnel from the potential for explosive gas and surface boils. Station-keeping requirements for the capping stack deployment vessel are determined using marine dynamic finite element analysis. This analysis takes into account the forces generated by the surface waves and radial outflow. Marine dynamics analysis then determines the deployment vessel’s response and if this can be counteracted adequately by an appropriate mooring or thruster arrangement. An arrangement of a properly outfitted ocean-going deck barge and an anchor handling tug supply (AHTS) vessel will allow for placement of a capping assembly over the well center while keeping the tug and personnel away from the hazards posed by the surface boil and LEL.

Barge selection and therefore AHTS is a function of radial flow velocities and flammable gas threat. These parameters will change significantly with well deliverability, gas-to-oil ratio (GOR), and water depth. When large gas plumes are predicted, a larger barge is necessary to keep the AHTS and crew away from flammable gas. In cases of high radial velocities, station keeping can be assured in a number of ways from anchor spreads or suction piles to “portable” thrusters. The AHTS would be sized appropriately for the deck barge and power to hold station with the barge end over the well center. Additional basic rigging components include a fair lead to guide the winch wire safely overboard, passive heave compensation, and rigging components for passing the capping stack from the offshore construction vessel to the AHTS wire for capping.

Engineered response solutions

In recent years, the industry has shown increased interest in modeling releases of varying rates, pressure, GOR, and water depth in locations across the globe. The desire is to capture what a capping operation looks like and requires in the way of resources during the pre-planning stage. Many of the older generation models wrongly predict the size of the surface boils created by a subsea release. The boil size governs the crane reach versus crane capacity requirements and can preclude a vessel from working safely outside the boil and associated LEL radius or at least severely limit vessel availability. This situation can occur with even the largest of heavy-lift crane vessels. By using state of the art CFD modeling, Wild Well can ensure that the boil size is predicted correctly.

As part of our engineered approach, the CFD simulations were validated against large-scale tests, and were carried out as part of a joint industry project, SURE, of which Wild Well was a participant. This five-year study ensures that the data provided by these simulations is accurate and reliable. CFD is also used to calculate vector forces expected on a deck barge, which influences station-keeping methods. If the surface effects of the blowout can be successfully overcome, further simulations are used to confirm that a capping stack can land on the subsea well against the flow out of hydrocarbons. This is known as a capping stack landing analysis and uses a special class of simulation called fluid structure interaction. This is a combination of CFD and finite element analysis. By combing these different analysis techniques, Wild Well is able to produce a clear understanding of the scale of the challenges to be overcome, and that the planned response methods will tackle them effectively.

Experience has shown that when it comes to responding to a shallow-water blowout, each incident is unique, but can be approached with similar tactics that are custom engineered for the specifics encountered. By offering engineered solutions for unconventional well control problems, Wild Well is able to assist its customers in all water depths with our unique approach to capping blowouts. Its shallow-water capping methodology is strategic, and incorporates statistical analysis and pre-planning operations as part of the overall approach to capping blowouts. Wild Well is able to use modeling to mitigate risk and predict the presence of flammable gas and surface boils at the well site in order to protect vessels and personnel from harm, while achieving the goal of getting over the well center safely with capping and containment equipment. •