Report cites environmental, cost benefits of Neodrill conductor

Offshore staff

STAVANGER, Norway – Neodrill has issued the findings of a Life Cycle Assessment (LCA) report for its CAN-ductor pre-rig installed conductor technology, prepared by Norwegian consultant Asplan Viak.

This concluded that the environmental impact of a well drilled using the CAN-ductor was 21-44% less than for a conventionally drilled well.

The reference case was the Cambo well drilled west of Shetland for operator Siccar Point Energy in 2018.

According to Neodrill, processes were detailed for both the CAN and conventional drilling, with results compared across eight environmental impact categories, including climate change and human toxicity.

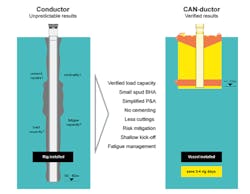

CAN’s main pluses were found to be reduced rig time and need for materials such as cement and steel in well casings.

The rig time was also four days shorter for the CAN-ductor compared to conventional technology, with further advantages identified with respect to cost, logistics, transport, and HSE.

Conventional well drilling technology had higher environmental impact across all categories compared to the CAN-ductor well drilling technology. Main results are as follows.

| Impact category | Unit | Conventional well | CAN-ductor | Reduced impact of CAN-ductor |

| Climate change | t CO2 eq | 1629 | 1112 | 32% |

| Human toxicity | t 1,4-DCB eq | 266 | 149 | 44% |

| Particulate matter formation | t PM10 eq | 8.8 | 6.0 | 32% |

| Terrestrial acidification | t SO2 eq | 16 | 11 | 32% |

| Freshwater Eutrophication | t P eq | 0.21 | 0.12 | 43% |

| Marine Eutrophication | t N eq | 1.01 | 0.69 | 32% |

| NOx | t NOx | 24 | 17 | 30% |

| Sox | t SOx | 2.5 | 1.9 | 24% |

In April, Neodrill’s introduced its first solutions for subsea templates. These include a BOP/xmas tree soft landing and load support system, wellhead support frame and a cementing system to control the flow of cement.

They are said to lead to a potential rig time saving of 3-4 days per well, and cost savings of NOK80-100 million ($9.4-11.75 million) per four-slot template.

07/01/2019