Case study: New methods of acquiring and transmitting data

Editor's note: This story first appeared in the November-December 2022 issue of Offshore magazine's first annual Offshore Oil and Gas Executive Perspectives Special Report.

By Chris Jones, Baker Hughes

Well construction in the offshore environment can be both technically challenging and expensive. However, over the past 30 years, the industry has improved on-bottom drilling performance immeasurably. The ability to drill complex well paths through challenging environments has been facilitated by access to real-time downhole data, control of the downhole equipment and increasingly sophisticated measurements deployed on drill pipe. These measurements and control systems have fueled many of the advances in remote operations and automation seen in drilling.

A large deepwater operator undertook a survey in 2015 where they broke down the time spent on each activity across their offshore portfolio. In deepwater, only about 15% of total well construction time was accounted for by on-bottom drilling. An attempt to improve that further should always continue, but there are greater returns to be made in attacking the efficiency of the 85% of well construction time where downhole data and control has not been available or often used.

Two recent Baker Hughes case histories show how new ways of acquiring downhole data have allowed its clients to change the way they operate, improving both safety and overall efficiency.

Deepwater tubing-conveyed perforation

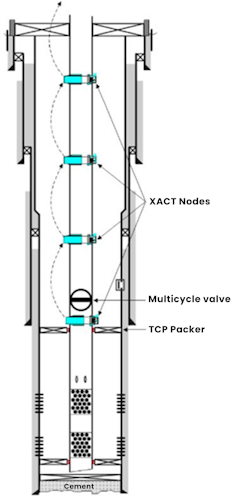

The first example is around a deepwater tubing-conveyed perforation operation. It is critical to know the precise downhole pressures exerted by the column of fluid in the well particularly when managing multiple sands at different pressures to avoid influxes or losses. Simply using surface measurements leads to such large uncertainties that the only way to manage the risk is to perforate the zones in multiple runs, which takes considerable time and resources.

The bottom most tool in this case was positioned so the client had continuous eyes on the actual downhole conditions at the reservoir. By planning the use of real-time downhole data into the well program, the client was able to significantly reduce the risk profile of the operation and moved to a single perforation run saving upward of five days of rig time and will be using this method going forward.

Deepwater cut-and-pull operations

The second example is taken from deepwater West Africa, in this case a cut and pull operation to enable a slot recovery. Understanding the condition of the casing and whether the casing is free is essential for a successful operation. However, cut-and-pull operations can be done many years after the initial drilling and logging of a well, and the conditions in the well may have changed significantly.

Until recently, measurements used to understand the casing condition required a dedicated wireline logging run, and time pressures often meant this essential information was simply not acquired, leading to significant rig time guessing where the best place to cut and pull was.

Baker Hughes developed the Casing Integrity and Cement Mapping tool (CICM), a collar-based tool that can be run in parallel with any operation where drill pipe is run in the hole. An already planned clean-out run was used to acquire these data with no extra rig time or requiring mobilization of additional manpower to the rig. A zone of the well was identified where there were significant solids built up behind the casing. Based on the data, the plan was modified and the subsequent cut-and-pull operations were carried out in two efficient runs with considerable risk and uncertainty reduction.

Challenging the industry

The XACT acoustic telemetry network provides a reliable and easy-to-use method of transmitting measurements in real time and soon to enable downhole control, and the CICM tool gives clients a new way to bring data to decision-making. These cases show a small subset of how downhole data acquired in new ways is allowing operators to change their operating process, avoiding non-productive time (NPT).

To eliminate NPT events, improve the efficiency and repeatability of operations—be it through equipment design, automation or redesigned processes—the industry must have the right measurements from the right places to do that.

Companies should continue to challenge each other and the industry. What if we had these measurements available, invisible seamless downhole control and precise downhole situational awareness in the other 85% of well construction time? Be creative to radically change up traditional processes and outcomes.

About the author: Chris Jones is Baker Hughes' vice president of Oilfield Services and Equipment, North America.