Real-time measurements, data management enhance operational efficiency

Rajan Chokshi

Weatherford

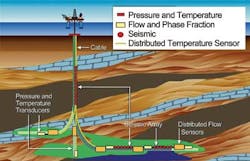

Whether operating in greenfield or brownfield environments, it is essential for oil and gas producers to obtain an accurate assessment of each asset's production capability. This enables them to develop prudent reservoir management and practical production strategies related to artificial lift, flow assurance, monitoring of installation integrity, and QHSSE. Also, as production activities move to more challenging locations like deepwater, subsea, and high-pressure/high-temperature (HP/HT) environments, the stakes become higher, making key production information even more valuable.

Conventionally, well test measurements, coupled with production logging and wellbore gradient surveys, have been used to assess the productive capabilities of a well. However, the frequency of such data captures is inadequate to address the dynamic production changes that are common in offshore installations. A related challenge is the lack of synchrony among these data sets, which often leads to inaccurate predictions of production behavior. This, in turn, can result in delayed, wrong, and often expensive intervention decisions.

A better solution to protect high-value investments in offshore and subsea installations is to take a proactive approach, using real-time downhole, subsea, and surface measurements to monitor and analyze well performance. This enables operators to curtail performance deterioration and deter imminent failure of downhole artificial lift equipment, as well as to tailor preemptive responses to potentially unsafe conditions such as hydrate, asphaltene, or wax precipitation.

Rather than wait until well tests or other symptom-discovery tests are conducted, reservoir managers would prefer to receive immediate information about changes like water breakthroughs or production response to secondary or tertiary recovery approaches. Having access to a well's downhole pulse—in the form of real-time downhole pressure and temperature readings, surface or downhole flow rates, and even water-cut measurements—is invaluable in performance- and compliance-conscious environments.

Different approaches

Today, subsurface technologies enable real-time production surveillance for pressure, temperature, flow, and vibration measurements. On top of that, recent advances in flow technologies permit measurement of water cut, as well as flow rates at wellheads or near central processing sites with partial or no separation. Such capabilities are especially useful in offshore environments, where valuable deck space that is typically allotted to expansive separation facilities could be saved by using inline, no-separation measurement technologies. A recent entry in this space enables real-time water-cut measurement in the production stream from a subsea well. Whether obtained from subsurface or surface instruments, measured data transmits telemetrically to a process platform en route to a shore-based field office or corporate location.

Subsurface measurements

Subsurface measurement technologies can be classified into two broad categories: electronics-based and fiber optics-based.

Electronics-based technologies are used for routine applications with moderate temperature and pressure ranges. These high-volume, economical gauges are used extensively for pressure, temperature, and vibration measurements in artificial lift monitoring, producer and injection well surveillance, and zonal production management applications. In artificial lift applications, the ability to combine the pump intake and discharge pressures with vibration data enables a continuous health check of equipment—in addition to proactive lift adjustments—so that equipment deliverability is matched closely to reservoir capability. Proactive lift management avoids underutilizing equipment by making adjustments to ensure that lift volume corresponds adequately with available, safe reservoir volumes. Conversely, it also aims to avoid lift equipment damage that can result from using incorrect settings or oversized equipment and outrunning reservoir deliverability. Recent developments in quartz-based technology enable sensing at higher pressures and temperatures with better resolutions, higher-frequency data updates, and up to 16 sensing locations on a single conductor cable.

Fiber optics-based downhole sensing technologies have been in use for more than two decades, and they have proven their value while providing improved reliability. Distributed temperature sensing (DTS) using fiber optics is a well-known application, but distributed acoustic sensing (DAS) is another emerging technology in this area. However, the availability of robust, reliable point and multi-point sensors for pressure, temperature, flow, and seismic measurements has expanded possibilities considerably. Optical cable, which typically contains three or four fibers, can combine multiple measurements in the same cable and even in the same fiber. This capability opens up a wide range of permanent downhole sensing possibilities in a single well, on a single cable.

DTS and array temperature sensing (ATS) point sensors each have advantages and disadvantages. For example, DTS allows spatial coverage over the entire length of a fiber-optic cable, but with a slower update rate and greater susceptibility to optical losses. ATS capabilities provide robust measurements up to ultra-high temperatures—even in the presence of higher optical losses—while delivering higher resolution and better stability with faster updates than DTS, but spatial coverage can be more limited.

Combinations of ATS and DTS are now available and can, in some cases, provide the optimal downhole temperature profiling and monitoring solution.

Fiber optics-based downhole flow measurement technology opens up unique possibilities, particularly for determining accurate allocation of multiple-zone production or injection. One notable feature of this nonintrusive technology is the bidirectional measurement capability for single- and two-phase flow measurements.

Surface measurements

Water cut is a key performance indicator for any well. Traditionally, this has been determined during periodic production well testing, but now this key performance indicator can be monitored continuously at the wellhead using near-infrared spectroscopy based water-cut measurement systems. These can be used on any multi-phase line, either topsides or subsea. They can be used for sensitive water onset detection and subsequent tracking of water production throughout the life of the well. They also provide the critical water-cut measurement role in modular multi-phase flow meters. The near-infrared sensor technology provides the most sensitive water detection technique available and is indifferent to salinity or water chemistry.

Multi-phase and wet gas flow meters provide oil, water, and gas flow rate measurements without the need for separation. That means a small footprint, which makes these meters ideal for offshore platforms where deck space is very expensive. Additionally, the meters deliver significant capex savings over the cost of a conventional three-phase test separator, especially for high-pressure and corrosive process stream applications. They are also easier to service compared to conventional separators, and have built-in diagnostics to track performance and alert operators as soon as a problem occurs. Safety is also improved by eliminating the test separator, and the associated volume of pressurized combustible hydrocarbons.

Converting data into information

All the above measurement devices sense data in real time, generating significant data streams. For reference, traditional applications that measure downhole pressure, temperature, and flow rate typically generate data streams in ranges of kilobytes to megabytes per day, per well. DTS applications, on the other hand, generate up to a gigabyte of information, and DAS tips the data scale in the terabyte range. These data volumes create significant challenges for conventional analysts, who typically handle a few point measurements for each well on a weekly or fortnightly basis. Traditionally, data analysis for lift or reservoir management occurs using standalone software packages.

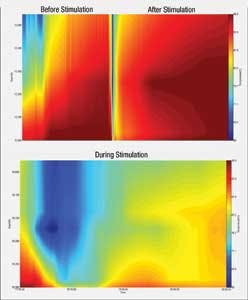

The promise of multi-stream, real-time measurements to improve reliability, safety, and environmental performance can be realized only with continuous analysis of high-frequency data. This approach begins with a full system that is capable of multi-dimensional visualization. For example, simultaneous visualization of DTS and downhole pressure data provides quantitative estimation of reservoir influx, whereas simple DTS visualization provides qualitative estimation of influx. Once data is processed through the visualization phase, relevant data slices must be parsed and routed to software packages for lift analysis or reservoir test analysis.

By combining real-time downhole, subsea, and surface measurements with powerful data management capabilities, proactive monitoring is quickly becoming recognized as an affordable, efficient, and leading-edge production solution for offshore environments.

Case studies

An offshore platform operator in Alaska's Cook Inlet needed an onboard test facility to provide regulatory allocation measurements and support production optimization efforts. With no process separation or production measurement equipment on board, well flow had to be directed to a land-based facility 5 mi (8 km) away. To improve efficiency and quality of measurements in these tight quarters, the operator installed a compact multi-phase flow meter. The installation required no expensive modifications to the platform, and there was no interruption to day-to-day operations. The operator now receives accurate and repeatable flow rate measurements with short test times because there are no purge times. This results in more tests for each well and highly accurate production tracking.

Visible benefits

For a newly developed field in the North Sea, a major independent operator installed multiple in-well sensors and collected initial results for the first 13 well completions. To meet a full array of downhole-monitoring and production-analysis objectives, the operator decided to monitor each well with a permanent downhole monitoring system (PDMS), including a pressure/temperature sensor, a full bore, two-phase flow meter, and a DTS monitoring system.

This all-optical reservoir monitoring system, installed on a single fiber-optic cable in each well, enabled effective real-time observation and management of reservoir parameters and lift performance, as well as completion integrity over the life of the field. These PDMS installations reduced well test times for the operator, improved production allocation across the field, and eliminated workover costs associated with typical pressure/temperature surveys—while providing highly accurate input for planned buildups or unplanned shutdowns.

Flexible, bidirectional monitoring

A North Sea operator chose to enhance production by converting a production well (producer) to a water-injection well (injector). The well was already equipped with a fiber optics-based PDMS to measure pressure, temperature, flow rate, and distributed temperature. To better manage the injection process, it was critical to determine the injected-fluid flow rates, since small fluctuations could have significant impact on oil production economics. The optical flow meter in place was ideally suited to the task.

Due to the true bidirectional measuring capability of the in-well optical flow meter, the conversion from producer to injector required no hardware or software changes to the flow meter or surface instrumentation. The flexibility of the PDMS resulted in a reduced initial equipment investment and significant time savings, with no need to install additional measurement equipment. Optical multi-phase flow meter installations are equally capabile for bidirectional flow measurement of either oil or gas.

Stimulation for improved production

An operator in the Gulf of Mexico had installed permanent downhole gauges (PDHG) in several wells to measure pressure, temperature, and distributed temperature. With one of these wells, these pressure and temperature sensors provided a real-time indication of significant slugging, as well as liquid production only from the lower zone. This prompted the operator to apply a corrective stimulation treatment, which resulted in stabilized, much higher production from the middle zone. Without downhole measurements, such rapid reservoir management response would not have been possible. In addition, such real-time measurements enable precise placement and monitoring of stimulation treatment. PDHG real-time monitoring systems allow a much more detailed understanding of reservoir production trends, the stimulation process, and post-treatment effectiveness.