P.2 ~ Extended-reach drilling systems address downhole challenges

View Article as Single page

Nontraditional drillstring materials

Advances in drilling and drill pipe technology for complex horizontal and ERD well profiles are continuously pushing for extended capabilities of the drillstring. Demands for performance include increased tensile strength-to-weight ratios and high-torque connections to overcome frictional drag forces and to achieve improved hydraulic performance, rate of penetration, control of well trajectory, and optimal hole cleaning.

Alcoa Oil and Gas reports that in one case, a well was drilled from a small production platform with a workover rig using a drillstring that combined 57⁄8-in. steel pipe with 2,500 m (8,200 ft) of 57⁄8-in. of its alloy drill pipe. The operator was able to drill 22% farther (more than 1,000 m, or 3,280 ft) than with steel drill pipe only (due to top drive limit).

The lighter drillstring increased pipe storage capacity on the platform, which had limited deck load capability. Increased overpull margin improved the ability to deal with stuck pipe or tight hole conditions, and reduced string stretch at total depth allowed pickup off bottom with the short derrick. This mix of steel and alloy drill pipe can increase the ERD operating envelope of smaller rigs and reduce field development project costs.

Alloy strings can be up to 40% lighter (dry weight) and more than 50% lighter (wet weight) than E-Grade steel drill pipe. Depending on the "blend" of the alloy pipe and steel, drilling depth capacity of an existing rig can be upgraded as much as 100%.

The alloy drill pipe is designed to use standard API tool joints. Tool joints are connected to the drill pipe using a thermal shrink fit technology. This connection uses a proprietary tool joint machined with six modified Acme threads per inch (RH) on a 3⁄8-in. taper per foot. The end of the pipe has a smooth, concentric shoulder, while the rest of the pipe is tapered through the transition zone. The inside of the pipe end of the tool joint displays the threads, the end shoulder, and the counterbore.

After assembly, an interference fit exists between the tool joint and the pipe. The annular section of the tool joint contracts after assembly and provides an additional interference fit. The pipe end is thus firmly gripped by the tool joint, providing a pressure-tight assembly and efficient transfer of tension, torsion, bending, and compression loads between the pipe and working connection.

High-strength steel pipe

High-strength steel grades are a type of alloy that provides better mechanical properties than API carbon steel. Alloy elements are added to the steel during smelting to strengthen it. This eliminates the toughness-reducing effect while increasing the material's strength by refining the grain size.

For ultra-deep or landing string applications, high-grade materials offer additional tensile capacity and impact strength compared to API grades. By using high-strength material to reduce tube body wall thickness, lighter drill pipe joints can be manufactured without compromising mechanical performance.

For complex drilling environments, including ultra-deep and extended-reach wells, deep offshore or high-pressure/high-temperature conditions, Vallourec Drilling Products, for instance, has developed high-strength grades including VM-140 DP, VM-150 DP, and VM-165 DP. High-strength grades are ideal when lighter drill pipe is required to minimize torque and drag in an ultra-extended-reach well. Reducing wall thickness also improves hydraulic programs, making it easier to reach drilling targets efficiently.

Hydromechanical drill pipe

Cuttings buildup can go unnoticed until the well signals problems such as reduced ROP, higher weight on bit (WOB) needs, erratic drilling torque, non-uniform rate of cuttings over the shakers, pipe buckling, high annular pressures, out-of-window equivalent circulating densities (ECD), drillstring whirl, and stuck pipe events. Remedies, which are also flags, include additional wiper trips, sweeps, and long circulating times.

When economically justifiable, mechanical hole cleaning devices (MCD) can enhance performances and are shown to be effective in achieving drilling efficiency gains in long hole sections and highly deviated wells.

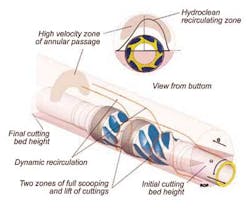

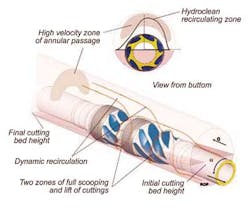

Mechanical hole cleaning devices, such as the Hydroclean tool, developed by VAM Drilling, are used primarily offshore to drill 17½-in. and 12¼-in. directional and deviated hole sections. The tool gradually erodes cutting beds height starting at low RPM by mechanically scooping cutting beds buildup where they cannot be avoided under normal drilling conditions. Cuttings are continuously scooped to a position above the drill pipe and sustained for transport in the high fluid velocity area of the annulus.

Despite worldwide experience with MCDs, few studies have been conducted showing how drilling performances can be improved with an all-inclusive system and measurable key performance indicators. Mixed results have also been reported ranging from total success to disappointments but generally lacking substantiating data. Such outcome is usually predictable because of the need to follow a blueprint from planning to execution. A hole cleaning management system approach for the well is needed, with defined expectations and measurable deliverables on the well site.

Bladed scallops and grooves produce a number of hydromechanical effects to increase cleaning efficiency of the drillstring. A drill pipe joint and heavy weight drill pipe comprise the tool. The tool provides full and immediate degradation of cutting beds while keeping more cuttings in suspension on the high side of hole, where fluid velocities are highest. Hydromechanical hole cleaning is achieved through the combination of three hydromechanical effects.

Scooping. Cuttings deposited on the low side of the hole are mechanically eroded at low RPM, which prevents cutting-bed buildup around the drill pipe.

Recirculation. Once lifted, cuttings are recirculated up to the high side of the hole and above the pipe.

Transportation. Regardless of the energy input exerted on the cuttings during recirculation, they travel only a certain distance and eventually resettle on the low side of the hole due to gravity. A "conveyor belt" has to be established to maintain cuttings transport to the surface.