Non-chemical products offer effective flow assurance solutions

Keshawa Shukla

McDermott

The "2014 Survey of Offshore Non-Chemical Flow Assurance Solutions" poster, which can be found in this issue ofOffshore, provides a comprehensive list of non-chemical solutions to flow assurance issues, and offers updated reference tools and design data for deepwater field development. The poster also provides details on products to manage flow assurance issues arising from wax and hydrate formations, emulsion/foaming/scale formation, slugging; detection of these phenomena; and remediation based on non-chemical solutions. In this endeavor, several leading contractors have made unique contributions by supplying information on their latest products.

Recent technological developments of non-chemical solutions can be applied to manage flow assurance challenges to ensure transport of oil and gas from wells to onshore facilities throughout the field life safely and economically. A combination of different non-chemical solutions can reduce capex and opex significantly and minimize/avoid injection of chemicals, thereby reducing maintenance costs.

The goal here is to present a brief overview of latest developments in non-chemical solutions for managing flow assurance challenges.

Flow assurance review

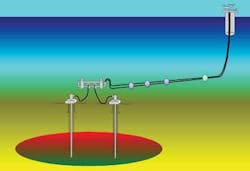

The oil and gas industry has had enormous success in the flow assurance arena over the past decade. Past experiences from subsea field developments have enabled engineers to be more cost-effective in design and operation. Still, flow assurance remains one of the key technical challenges operators face in deepwater.

The most challenging flow assurance issues are the management of wax, hydrate, asphaltene, emulsion/foaming/scale, slugging, and pigging. As water depth increases, issues related to multi-phase flow, production chemistry, pipeline integrity, subsea and surface operations are magnified.

For instance, at the low temperatures of subsea conditions, heavy hydrocarbons may precipitate as wax and asphaltene, and mixing of hydrocarbon fluid and water may form hydrate, restricting the flow. During shutdown of a subsea pipeline, wax/gel may form and solidify when a crude oil cools below its pour point.

Under high pressure conditions, high CO2 and H2S contents in production fluid with water can lead to corrosion. Under high pressure and temperature conditions the relatively large amount of produced water may form scales. Sand production from formation can cause erosion in a subsea pipeline.

At turndown flowing scenarios, liquid build up at a production riser base can cause severe slugging and separation problems in equipment lacking insufficient backpressure. All these issues can cause operational problems from downhole to processing facilities.

In recent years, flow assurance has combined multi-phase flow and production chemistry to manage the interface between reservoir and topsides processing, and is not only based on hydrates, wax, scale, asphaltenes, and corrosion, but also includes network modeling and transient multi-phase simulation to answer the operability of the designed facility and risk management.

Therefore, the subsea systems should be properly designed in a cost effective way, taking into account the above factors starting from concept selection through detailed design of subsea field development. The effective preservation of fluid heat in pipeline systems is one of the most important design parameters, especially for preventing wax and hydrate solid formations/depositions.

Non-chemical solutions

The experience of non-chemical solutions and innovative technology is encouraging. Several non-chemical solutions products and approaches are now available which can be applied to deepwater and ultra-deepwater field developments. The poster also includes properties of non-chemical materials, their recent subsea applications and vendor information. Based on the survey, the available non-chemical solutions can be classified in three categories, 1) active system, 2) passive system, and 3) other innovative methods. A brief account of these systems is given below.

Active systems. These include electrical heating, hot fluid circulation, exothermic processes, line pipe (internal), coiled tubing, bundled pipelines, and through flowlines (TFL). They require input of energy in the form of work or heat. The important characteristics of active systems are the power requirement, circulation fluid types, frequency or continuous usage, increase temperature/pressure, and offset distance. For instance, direct or indirect electrical heating requires energy in the form of electric current to supply heat to a pipe wall. Hot fluid circulation requires heat to elevate temperature of the circulating fluid and work to pump the fluid through the pipeline. The opex for active systems can be offset by reducing the operating costs required to keep production fluid out of hydrate or wax conditions during shutdown operations. Active heating can remediate hydrate plugs safely and can remediate blockages in hours.

Passive systems. These include buried pipe, pipeline wet insulation, pipe-in-pipe (PIP) dry insulation, vacuum insulation, insulated flexible pipe, riser towers, and internal insulation. They do not require an input of energy such as work or heat. Heat retention is achieved by surrounding the pipeline with materials that offer a high resistance to heat transfer with low thermal conductivity. The important characteristics of passive systems are the physical properties such as thermal conductivity, coating thickness, U-value, heat capacity, and density of materials. For instance, thermal insulation systems are wet insulation, dry (pipe-in-pipe) insulation, and pipeline burial. Flexible pipes can be insulated, but their outside diameter is intrinsically large and limits the amount of required insulation. Costs for passive insulation systems involve capex. A combination of pipeline wet insulation, burial, and trenching can provide a cost effective passive system. The insulation system can impact on-bottom stability, cost of installation, and field-joint design. Riser insulation may impact fatigue.

Wet insulation. There are now several advanced wet insulation materials available for different subsea applications, such as solid polymers polypropylene (PP), novolastic, polyurethane, and syntactic foams glass syntactic polyurethane (GSPU). They can achieve low U-value for heat retention in subsea flowline systems including jumpers and hardware. The wet insulation is directly coated to steel pipes and placed on the seabed exposed to seawater. It is typically tailored to withstand compression due to hydrostatic head in deep water. It offers good mechanical properties along with an extended track record in the offshore oil and gas industry. Wet insulations are available in several forms, such as 3-layer, 5-layer and 7-layer consisting of FBE, adhesive foam PP, insulation materials, and an outer shield.

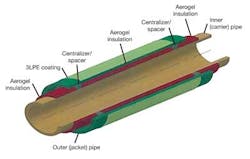

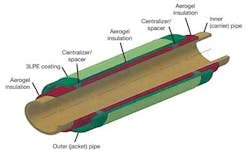

Pipe-in-pipe (PIP) insulation. For heavy oil production, PIP insulation can provide better heat retention to maintain fluid temperature above the safety margin of hydrate and wax temperatures during normal operation achieving lower U-Values (~ 1.0 W/m2-K or less) and high insulation performance. It also offers a significant reduction to both material and installation costs. Such insulations have been tested at deep water depths. In PIP, a pipe is inserted inside another pipe. The created intermediate annulus is used to hold a dry insulation material which is protected by the outer pipe from hydrostatic pressure and water penetration. In PIP insulation, the inner (carrier) pipe is insulated with a low conductivity dry insulation such as aerogel or low density polyurethane foam. The outer pipe is typically steel or polyethylene, depending on applications. In case a rigid outer pipe is required, an air gap exists between the outside diameter surface of the insulation and inside diameter of the outer pipe. The effective conductivity of the air gap is reasonably low and adds to the heat resistance of the system.

Other innovative methods. Other technological advances to address flow assurance problems include: cold flow technology for un-insulated pipe, collapsible pipe, coiled tubing remediation, phase change insulation, internally insulated corrosion resistance pipeline, and flow optimized system architecture with limited applications.

Conclusions

Non-chemical solutions can be applied safely in thermal management of hydrate and wax problems for subsea field developments. When the flowline production system including water stops and subsea hardware are not insulated adequately, cold spots may lower the temperature substantially and enhance the risks of hydrate and wax formations/depositions. Application of PIP insulation combined with wet insulation can prevent such risks effectively and reduce capex/opex by minimizing the use of chemical inhibition, pigging frequency, and depressurization. Even in PIP flowline/flexible riser production systems all subsea jumpers, structures, equipment, and water stop assembly involved should be insulated adequately to maintain fluid temperature above the hydrate and wax formation temperatures. The combination of chemical inhibition, depressurization, pigging, and dead oil circulation can help reduce opex for economical operation of the subsea production system throughout the life of field.

Editor's note

To see the full version of this article, please go to:http://www.offshore-mag.com/articles/2014/03/non-chemical-products-offer-effective-flow-assurance-solutions.html.

The author

Keshawa Shukla, Ph.D., is senior manager of flow assurance engineering and global subject matter expert at McDermott in Houston, Texas.

Acknowledgment

The author wishes to acknowledge the McDermott business development teams in Houston and London, and the subsea engineering group for supporting this publication. Special thanks go to Miranda Smith and Jason Martinez.