Well integrity initiatives improve deepwater well construction-full

Brent Emerson

Weatherford

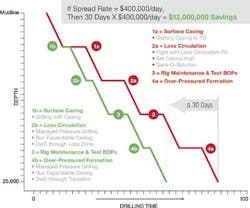

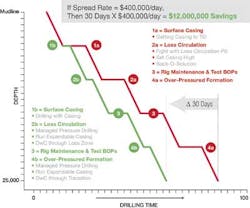

As offshore E&P operations continue to move into deeper waters and more geologically complex reservoirs, the risks and costs of well construction continue to rise as well. Deepwater operators are tasked with minimizing these risks and costs while building high-integrity wells that not only meet long-term production objectives, but also comply with governmental regulations on safe and environmentally responsible practices.

Assuring well integrity for the long term means successfully navigating through a myriad of well construction challenges. These include geologic uncertainty, narrow pore pressure/fracture pressure gradients, and borehole instability risks. Without understanding these challenges, the operator runs the risk of not getting the well to target, improper casing design and equipment performance, inadequate zonal isolation, lost circulation and ultimately, loss of the well.

Addressing these challenges requires a collaborative approach to well construction between the operator, the drilling contractor, and the service companies that contribute to the project. It also requires a sophisticated solution that orchestrates many drilling, casing running, and completions technologies with multi-disciplinary teams that possess the necessary application expertise.

The following reviews the major well integrity initiatives that might be implemented at each stage of well construction, and provides field examples of how these initiatives impacted well integrity.

Early involvement essential

Ensuring well integrity ideally begins before the drill bit ever enters the seafloor—at the early stages of well planning. Upfront discussions during the planning stage give all parties a thorough understanding of the operator's ultimate production goals for the well and the geologic and geomechanical challenges expected in the reservoir. With this information, the multi-disciplinary planning team can agree to the best combination of tools and services—from the drill bit to the cement—to ensure the well reaches total depth (TD) on time and within budget.

Early collaboration also allows for contingencies to be prepared should the construction program deviate from the original plan. Having secondary tools and procedures in place to drill through a weak part of the formation, for example, will allow drilling to commence faster to TD rather than having to develop a solution "on the fly." The well will thus be installed with fewer surprises, resulting in more reliable and optimized well performance.

Drilling to depth

Assuring deepwater well integrity during drilling translates to applying the proper services to successfully navigate through narrow pore pressure/fracture pressure gradients, ensure robust zonal isolation, and minimize kicks or lost circulation events, all while reaching TD at a high rate of penetration (ROP). This begins with measurement-while-drilling (MWD) services such as Weatherford's hostile environment logging (HEL) MWD system, which combines a multi-frequency resistivity, high-temperature sensor with real-time information logging-while-drilling (LWD) data transmission services.

If trouble zones cannot be avoided without adding costs and time to drilling, all stakeholders should work together to develop the best drilling solution. Managed pressure drilling (MPD) systems, for example, enable operators to drill through troublesome pressure zones while maintaining control of the well and minimizing nonproductive time (NPT). Rotating control devices (RCD), a major component of a MPD system, create a closed-loop drilling environment, enabling ultra-precise control over fluids flowing into and out of the well. Using the Weatherford Microflux system, MPD allows for detection and effective management of minute fluid influxes or losses, thereby preventing major well control incidents from occurring.

Deploying solid expandable liners and drilling with casing or liners provide other means of isolating drilling hazards and achieving zonal isolation. Solid expandable tubulars not only provide a unique isolation solution for planned and contingency applications, but also they conserve hole size to help reach TD and enable the optimal completion. Drilling with liners or casing through depleted reservoirs or a severe lost circulation zone is an effective solution to isolate these hazards and ensure planned casing seats.

An operator drilling offshore Vietnam required such a contingency loss-control option while drilling a 12¼-in. open hole section. A monobore open hole expandable liner system was run to a TD of 10,488 ft (3,197 m) at a rate of 1 m/min to prevent fluid losses. Cement displacement and liner expansion operations (from 11¾ in. to 12¼ in.) were conducted successfully. The liner system isolated the lost circulation zone for continued drilling of the 12¼-in. open hole. The system also provided sufficient annular bypass for cementing the 10-in. x 135⁄8-in. liner at planned depth, without further losses.

Regardless of the drilling method selected, successful execution depends on collaborative engineering and operations to minimize risks, reduce flat time, and deliver well integrity.

Smooth running

Successfully drilling each interval in a deepwater well is a precursor to running the casing to TD and cementing it in place. Underreamers also help get the pipe to depth, by enlarging the hole and allowing pipe joints to reach their planned distance in the wellbore without having to step down in pipe size prematurely. The resulting full-gage, high-quality hole also aids subsequent completion and cementing operations, and allows for better management of equivalent circulating density (ECD) in softer formations where lost circulation events are a concern.

Such a solution was instrumental in the drilling of a 12¼-in. pilot hole in a deepwater Gulf of Mexico well. Weatherford deployed its RipTide Rathole Killer drilling reamer beneath an MWD turbine restriction and enlarged 730 ft (223 m) of the pilot wellbore to 14½ in. The tool minimized the rathole to less than 15 ft (4.6 m), which allowed the operator to set the casing shoe in the desired zone. It also eliminated a dedicated clean-out run, saving three days of rig time valued at nearly $3 million.

During casing running operations, the make-up of each casing connection is also critical for well integrity. Ensuring connection integrity reduces NPT and operator costs, and helps operators stay in compliance with increasingly stringent regulatory requirements. And connection integrity is becoming even more critical as deepwater well construction operations increasingly embrace new tubular designs containing premium connections with metal-to-metal seals.

This calls for the use of specialized, propriety technology that can ensure gas-tight seals designed to withstand high-torque and bending stresses. The JAMPro (Joint Analyzed Make-Up) torque monitoring system, for example, provides real-time monitoring of tubular make-up for each connection. The system monitors the torque, turns, and speeds of any power tong in real time, and uses this data to help control make-up and ensure that each connection conforms to manufacturer specifications.

The real-time monitoring and control afforded by the system allows the onshore operations team and offshore crew to collaborate during the tubular running job. Such collaboration can quickly identify potential connection problems while the operation is still going on, which minimizes the risk of leaks or damage to any connection.

Further efficiency improvements are realized by deploying services that allow for offline preparation of pipe prior to delivery to the rig, without compromising well integrity. By making up doubles or triples of pipe joints onshore, for example, operators realize efficiency gains and increased safety by reducing the amount of manual intervention required on the drill floor.

Reducing the surge

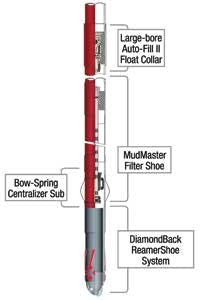

The integrity of the well may also be compromised while running casing through tight tolerances. Running the casing too quickly may not allow the wellbore pressure to be relieved quickly enough, resulting in a surge in the open hole that serves to damage the formation. Simulation models may be run to gauge the effective tripping speeds to minimize losses and reduce the surge pressures in the open hole. Further surge management is realized by running a diverter tool in conjunction with auto-fill float equipment to divert displaced fluids from the running string into the annulus. By quickly moving wellbore fluid out of the way of the descending casing string in this manner, tripping speeds can be increased with less risk of building up surge pressure and fracturing the formation.

To prevent buckling and reduce axial drag and friction while running casing, centralizer subassemblies may be deployed as part of the tripping operation. A centralizer sub keeps the casing string central to the wellbore while running, and new sub designs can contract to pass through tighter ID sections of the well. Regardless of whether one is rotating or reciprocating the casing string, the centralizer sub allows casing to reach its intended TD with less risk of damage that can shorten its operating life.

An operator needed to gain control of an ultra-deepwater well in the Black Sea to avoid formation damage, while minimizing rig time and mud losses. In response, Weatherford deployed its WellMaster system. For this well, the WellMaster solution consisted of a premium liner-top packer, WPHS liner hanger, an auto-fill collar, a filter shoe, a multiple-opening diverter tool, and rotating centralizer subs. This solution allowed the operator to run a liner to a total depth of 16,213 ft (4,942 m), while isolating a weak formation, eliminating a potentially costly problem and saving considerable rig time. A flawless cement job was performed at speeds of up to 45 ft/min (13.7 m/min)—with zero mud spills and zero recordable incidents.

Cementing integrity

There is more to ensuring a high-integrity cement job than just the cement. It also requires a combination of proper planning, reliable technology, and collaborative field operations that work toward successful execution. Planning begins with gaining a thorough understanding of the cementing challenges and objectives in deepwater wells.

Stage cementing is one option for deepwater wells that allows individual sections, or stages, of the well to be isolated and cemented independently. Annular casing packers are typically deployed in stage cementing applications. As their name implies, they are deployed down the annulus to their desired setting depth, and the packers are then inflated to close off the annulus below. Cement is then applied in that zoned-off section, but much less than would be required for a longer interval. As a result, the pressure exerted by the weight of cement against the wellbore wall is reduced.

Another cementing option gaining traction among deepwater operators and regulators alike is reverse cementing. Unlike conventional methods in which a great deal of pressure is applied downhole to move the cement up the annulus, reverse cementing pumps cement down the ID of the well to a certain point, whereupon the cement passes through a liner reverse cementing tool that diverts flow from the ID to the OD of the string.

The cement moves down the annulus to bottom. The displaced mud then comes back up the ID until it reaches the crossover tool and exits out to the annulus once again, but at a shallower depth and with a lower hydrostatic head above it. The mud then finishes its trip to surface up the annulus.

Reverse cementing allows the cement to freefall (in vertical wells) down the annulus to bottom, rather than requiring significant pumping pressure to pump the cement up the annulus and place greater pressure on the wellbore wall. In essence, reverse cementing may allow for a better cement job, but with less risk of formation damage and lost circulation.

The concept of well integrity, safely getting pipe in the ground and securely cemented in place, is relatively easy to explain but much more challenging to implement in the field. Ensuring that each step of well construction occurs seamlessly, and that adequate contingencies are in place to address a loss of wellbore control, requires a methodical and collaborative approach to well planning. Every party involved in well construction, from the operator to every service provider, must be willing to share their insight and learn from others if a high-integrity and profitable well is to be realized.