RPSEA continues technology advance with ultra-deepwater R&D projects

Gene Kliewer

Technology Editor, Subsea & Seismic

The business of advancing technology continues as the Research Partnership to Secure Energy for America (RPSEA) moves forward with its transition into the role of technical coordinator under NETL/DoE (National Energy Technology Laboratory/US Department of Energy) management in 2015.

RPSEA's Ultra-Deepwater Conference recently held in Houston not only reviewed the status of programs under way, but also took a look ahead at how the organization might function in the future.

While RPSEA Strategic Advisory Committee representative Van Romero of the New Mexico Institute of Mining & Technology noted that there may be legislation to re-institute the program in the future, it would continue to function in its original form until the end of this year. Taking up the explanation of near-term changes, James Pappas, acting RPSEA president and Ultra-Deepwater Program vice president, said the existing programs would be under NETL/DoE management after year's end, at which point RPSEA would become the technical coordinator for ongoing research and development.

Moving beyond 2015, Pappas pointed at the US Department of the Interior's Ocean Energy Safety Institute (OESI) program as one place RPSEA's experience and abilities would be useful. OESI is intended to facilitate exploration and production in collaboration with the public, and has drilling as its initial focus. The Institute is designed to facilitate research and development, training, verification of best available and safest technology (BAST), and implementation of operational improvements in offshore drilling safety and environmental protection, blowout containment, and oil spill response. It is functioning under a $5-million, five-year agreement with Texas A&M Engineering Experiment Station's (TEES) Mary Kay O'Connor Process Safety Center in partnership with the University of Texas and the University of Houston.

This presents an opportunity, Pappas said, to overcome an information-sharing barrier among operators, and a place to collect data on "near-miss" safety events, along with the establishment of common terms to improve recognition and discussion of such events. He also said the establishment of BAST criteria requires industry participation.

Other current and prospective joint industry projects (JIP) he mentioned that could benefit from RPSEA participation included the Paulson 3C downhole fiber optics program, the Battelle work on technology to replace air guns in seismic surveys, and the Bastion-led work on a pyrotechnic intelligent subsea accumulator.

Technology reports

The final results of several JIPs along with interim status discussions were presented at the UDW conference.

Phase 1 of the Ultra-Deepwater Dry Tree System for Drilling and Production in the Gulf of Mexico was summarized by Jenny Yan Lu of DNV GL. The project objective was to develop and mature two dry-tree drilling platform concepts that would be cost competitive with a spar. The basis for the project was that with a dry tree, the well could be drilled, completed, and worked over from the same floating platform. Also, such an installation would be less dependent on mobile offshore drilling unit (MODU) support and would be more cost-effective for marginal fields with the installation and commissioning taking place quayside. While there were a number of dry-tree system concepts, they had in common the reduction in heave motion needed for a topside BOP. The two approaches selected were Houston Offshore Engineering's paired column design and the Kvaerner field development long-stroke design.

While there are some vibration induced motion details that need further study, the HOE hull configuration was found to be usable in central GoM metocean conditions in 8,000-ft (2,438-m) water depth.

Jelena Vidic-Perunovic of Doris Inc. discussed the results of the study relating to the prospective use of round hull floaters in the GoM. While the Phase 1 concluding report is not yet complete, the study suggests that there are advantages to circular-shaped hulls, and that VIM studies were needed to investigate the response characteristics.

DNV GL is the prime contractor and is responsible for making sure both concepts are developed with the same design basis and that each concept has addressed its unique design challenges.

Reverse-circulation cementing

Circulation in deepwater wells is a topic of research interest, too. RPSEA heard the final report on deepwater reverse-circulation primary cementing from Crystal Wreden of CSI Technologies. The project objective was to assess reverse circulation cementing to reduce circulation pressure requirements in deepwater. Accessing the annulus from the rig floor in deepwater is one hurdle, and new downhole tools may be the answer. One such tool under development is a crossover design based on a gravel pack tool that can work for both conventional and reverse-flow cementing is probably the quickest route to success. A second tool under study is one that can switch the cement flow between the annulus and the drill pipe, and this maybe the better long-term solution. Contributing to the work is a program developed for use by the University of Houston (UH) that can simulate reverse cementing. Existing programs worked for onshore cementing, but deepwater cementing is not as straight-forward. The new program takes into account the fact that deepwater reverse cementing shows higher temperatures than do onshore applications. Also the equivalent circulating densities differ between conventional and deepwater reverse circulation cementing. With these additions to the program, the UH derivation can figure a critical depth equation that can indicate whether there is an ECD benefit to reverse circulation. Among the benefits determined by the research is the fact that reverse-circulation cementing can reduce the pumping time required for placement and that it can cause the cement to thicken in a shorter time and higher in the hole than conventional methods.

Another related program concerns developing best practices for cementing in deepwater using oil-base or synthetic-base drilling muds. Since OBM and SBM are incompatible with cement slurries, their beneficial properties become a detriment when cementing. The incompatibilities from cross contamination, mud residue in the hole, fluid swapping, and other fluid interactions can result in reduced compressive strength of the cement as well as result in channelling, downhole gelation, and poor cement bonding. The first phase of this investigation is concerned with the chemical reactions between the mud and the cement. The second phase is a large-scale model and field trials, as well as new spacer technology and practices.

Intelligent ram actuator

GE Global Research is leading a project to develop an auto-compensated sensor that can detect the presence of drill collars, tool joints, and other unshearable items in and around the BOP rams. The first phase of this study will encompass developing the sensor and signal conditioning approach, developing sensor error correction ideas, and evaluation of mechanical and software integration of the sensor with the BOP. Phase two will cover the sensor design and prototype construction and testing. Emad Andarawis of GE is the lead.

Nanotube umbilicals

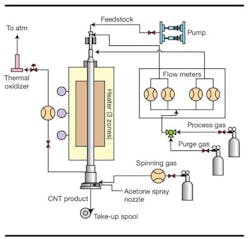

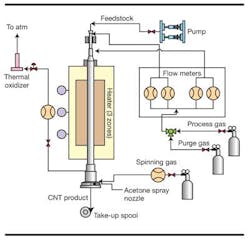

This program aims to develop and produce high-conductivity umbilicals that can both withstand installation and deliver the higher service loads expected as projects go into deeper waters and cover longer distances. The work has led to construction of a prototype double-wall carbon nanotube wire with a polymer jacket. The polymer jacket adds mechanical integrity, abrasion resistance, and eases handling of the conductor. According to Christopher Dyke of NanoRidge Materials Inc., the presenter and a principal investigator, the target is a conductor that matches the resistivity of copper (10-6 Ω•cm at 37.92 MPa/5,500 psi), but at less than 20% of the weight. At present, the program is refining the prototype tool that produces the carbon nanotube wire to optimize the purity because the wire must not have any amorphous carbon and is working to meet the desired resistivity. The machine can manufacture 100-m (328-ft) long carbon nanotube wires.

In a related but separate project, the GE Global Research Center is early in a project to develop high-voltage DC current subsea connectors. Qin Chen of GE said the connectors are a critical part of the DC subsea electrification system, and pointed out that the connectors needed both mechanical and electrical connections to function in that role. The first phase of the project is to establish the requirements for such connectors and to compare them to the existing hardware. The second phase will be to design, qualify, and then build a prototype.