Autonomous systems and agentic AI transforming offshore logistics and production

Key Highlights

- Agentic AI enables real-time, self-correcting offshore logistics plans that reduce vessel demand and non-productive time.

- Hybrid AI-physics models improve production forecasting and anomaly detection.

- Autonomous drilling systems are achieving higher rates of penetration and reducing human oversight.

- Successful scaling of agentic AI depends on outcome-based metrics, standardized infrastructure, trust governance, and seamless integration into existing workflows.

- Offshore environments serve as the ultimate testing ground for AI, where complex physical systems and weather conditions challenge and advance autonomous technologies.

By Rajiv Murali, Boston Consulting Group

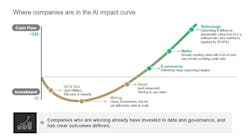

Oil and gas companies, like those in many industries, are betting hundreds of millions on artificial intelligence (AI). In offshore operations, agentic AI can drive the next frontier through autonomous systems that sense, decide and learn continuously within defined guardrails. But to truly realize the potential, it is important for companies to invest in workflows, change management, and appropriate governance and controls with clarity on how to “cash the check.”

This article will highlight three areas where agentic AI can reshape offshore operations.

1. Integrated planning and scheduling

Every offshore day involves hundreds of interdependent activities: vessel runs, crew changes, fabric maintenance, well interventions and translating all into an inter-operable logistics plan. Each activity is constrained by weather, permits, personnel, inventory and infra availability and other factors. Historically, these plans lived in spreadsheets, rebuilt manually when conditions or priorities change.

Agentic AI can reshape that manual, reactive cycle with a mixed-integer optimization core linked to a network of self-learning agents. Each agent represents a vessel, base or work team, and it operates inside hard limits like crew-rest rules, simultaneous-operations (SIMOPS) restrictions and met-ocean windows. The system fuses live AIS tracks, weather forecasts and ERP updates; translates individual team requirements (e.g., maintenance, production operations) into implications for vessel types, deck space, bed requirements and timing schedules to build a plan; and updates automatically when conditions shift to minimize downtime, with multiple options for humans to choose from, based on priorities.

Operators employing agentic AI in offshore activities are already realizing value:

- In Northern Europe, an AI-driven scheduler reduced platform-supply-vessel demand by 40%—about $100 million per year—by recomputing sailing plans within minutes of a weather hold.

- In the Middle East, a cloud-native planner spanning 80 vessels cut delays and non-productive time by 60% through real-time route and cargo re-optimization.

- In the Gulf of America, these systems will help operators save several days of non-productive time from more frequent hurricane events.

These programs show how integrated agents and optimization heuristics can turn logistics from a static plan into a living, self-correcting network.

2. Production optimization

Traditional simulators remain the backbone of flow assurance, but they struggle with real-time uncertainty. Hybrid AI and physics models now act as fast surrogates, trained on years of sensor and production data to predict pressure, flow and temperature with sub-minute latency.

Agentic controllers wrap these models into a closed-loop control system. Agents detect anomalies (e.g., slugging, rising water cut or compressor surge), simulate corrective actions and autonomously adjust choke positions, gas-lift rates, compressor settings or injection volumes. Each action and outcome are logged, retraining the model for the next cycle.

Field deployments in the North Sea and Gulf of America have reported 3-10% production uplift and faster recovery from upsets. These results align with findings from Boston Consulting Group, noting that while most operators remain early in adoption, hybrid, data-driven systems can unlock significant value once embedded at scale. That gain stems from continuous adaptation; wells and facilities self-tune to maximize throughput while honoring constraints on pressure, interference and equipment limits. Engineers stay in the loop, approving or overriding recommendations (e.g., interventions) through explainable dashboards—thus, trust built through transparency, not black boxes.

3. Autonomous drilling

Drilling pushes automation hardest. Current closed-loop systems already regulate weight-on-bit, rotary speed and mud flow through nested inner and outer control loops. The next step is agentic drilling, where AI agents interpret downhole telemetry, test scenarios through hybrid physics-AI models and refine steering parameters autonomously.

In 2024, SLB and Equinor achieved a 60% increase in rate of penetration (ROP) on Brazil’s Peregrino C platform, with most footage drilled autonomously. Halliburton’s LOGIX system has surpassed 12 million feet, improving ROP by up to 30% with 87% of footage drilled without human input.

These systems already adapt in real time; upcoming generations will coordinate across wells, applying reinforcement learning to optimize campaigns end to end. The driller’s role shifts from manual control to supervising agents that learn the rock as they cut it. While these developments are still in early stages, they carry tremendous promise for the AI oil field of the future.

The future of agentic AI

Agentic AI can deliver substantial value, but scaling it safely requires rigor.

Those that adopt and implement the technology successfully are expected to be able to:

• Tie agents to outcomes: Each must link to a measurable metric (e.g., vessel days, barrels or hours per well) and tie it to an executive’s KPIs.

• Build common infrastructure: Standardize data historians, control gateways and have cybersecurity layers across pilots for a multi-basin, multi-facility operator.

• Govern for trust: Define boundaries between advice and actuation, stage autonomy levels with appropriate roles for humans in the loop, and maintain full audit trails.

• Enable adoption in the field: Integrate agents seamlessly into the workflows, get the field accustomed to AI performances, build tolerance against error and use agentic products as a partner versus adversary to enable scale.

Offshore remains the ultimate proving ground for AI where algorithms meet steel, complex physical systems, weather and crews. Those who embed agentic AI into daily operations—not just proofs of concept—will define the next performance frontier.

About the Author

Rajiv Murali

Rajiv Murali is a managing director and partner at Boston Consulting Group (BCG), based in the San Francisco Bay area. He works with energy and industrial companies to drive digital transformation, and operational and capital efficiency. Murali specializes in applying data analytics and AI to enhance decision-making, safety and workforce productivity across heavy industries.

Before joining BCG, he worked in field engineering at Schlumberger and co-founded Enfrien Technologies, an energy efficiency startup. He holds a bachelor's degree in electrical engineering from the Indian Institute of Technology, Madras, and a master's degree from Northwestern University’s Kellogg School of Management.