ADIPEC 2025: Oxford Flow director highlights offshore pilot with ADNOC to cut methane leaks

Key Highlights

- Valves are responsible for up to 60% of industrial methane leaks, yet are often overlooked in emissions strategies, posing regulatory and environmental risks.

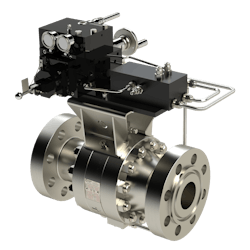

- The ES stemless control valve eliminates leak paths by removing external stems and packing, reducing failure points and simplifying installation in offshore environments.

- The valves are currently being piloted in live operating conditions at Upper Zakum and Das Island, for both offshore and onshore environments.

By Ariana Hurtado, Editor-in-Chief

During the ADIPEC Exhibition and Conference this week, Brendan Hegerty, director of growth, product management and sustainability with valve manufacturer Oxford Flow, chatted with Offshore about its valve technology and how its helping operators reduce emissions.

With a pilot underway with ADNOC, Oxford Flow has been demonstrating how its ES stemless control valve can eliminate fugitive emissions in offshore operations and address a source of methane leaks. During the commercial trials, the valves are being piloted in live operating conditions at Upper Zakum and Das Island. The pilot is being conducted in both onshore and offshore environments.

Offshore: According to Oxford Flow, valves are responsible for an estimated 60% of industrial methane leaks, yet they’re often overlooked in emissions strategies. Why do you think that is, and what’s at stake for offshore oil and gas operators?

Hegerty: Valves can sometimes be overlooked in emissions strategies because failures have historically been accepted as inevitable and reporting focuses on what’s already emitted rather than what could be avoided. Yet leaking valves, which research from University of British Columbia suggests are responsible for an estimated 60% of industrial fugitive emissions, pose direct regulatory, operational and environmental risks. By eliminating leaks through design, offshore operators can reduce emissions and improve safety and reliability simultaneously.

Offshore: Can you walk us through the recent ADNOC pilot—what are the goals, how is it being implemented and what measurable emissions reductions are you looking to achieve?

Hegerty: Our ES stemless control valve is currently being piloted with ADNOC at Upper Zakum to demonstrate its ability to eliminate fugitive emissions in live offshore operations. With a compact, low-maintenance design, it removes frequent failure points and makes installation simpler. The ongoing pilot continues to provide insights under real-world conditions, supporting ADNOC’s decarbonization targets and highlighting the potential for measurable emissions reductions.

Source: ADNOC Group Facebook; posted on Oct. 20, 2022

Offshore: How does Oxford Flow’s stemless ES valve design eliminate a key leak path, and what implications does this have for offshore reliability and maintenance cycles?

Hegerty: The ES stemless valve eliminates the primary leak path by removing the external stem and stem packing, which are the main sources of fugitive emissions in conventional valves. Its electrohydraulic drive and pressure-balanced design reduce mechanical stress, erosion and turbulence. For offshore operations specifically, this means higher reliability, long-term zero leakage, smaller, lighter valve packages, and extended maintenance cycles, reducing downtime and operational costs.

Offshore: Offshore environments are harsh and high-risk. How does the ES valve perform under extreme conditions compared to conventional valve technologies?

Hegerty: Offshore environments are unforgiving, with constant exposure to high pressures, vibration and corrosion that quickly degrade conventional stemmed valves. The ES valve is designed for these extremes; its stemless, axial-flow design eliminates the main leak path and wear point, achieving zero fugitive emissions and exceptional reliability. With a single moving part and no external linkages, it resists corrosion, minimizes maintenance and delivers safe, consistent performance where intervention is costly and conditions are harsh.

Offshore: What role do you see smart valve technologies playing in the future of real-time monitoring and emissions reporting for offshore assets?

Hegerty: Smart valve technologies will be central to real-time monitoring and emissions reporting offshore. By providing accurate, continuous data on condition, performance and seal integrity, they enable operators to move from reactive maintenance to proactive asset management. This supports regulatory compliance, reduces fugitive emissions, and creates opportunities to quantify avoided emissions and demonstrate measurable environmental performance, helping offshore assets operate more safely, efficiently and sustainably.

Offshore: As Oxford Flow presents at ADIPEC, what message are you hoping to send to offshore oil and gas operators, engineers and decision-makers attending the event?

Hegerty: At ADIPEC, we want to show Middle East operators that decarbonization is possible without disruption. Reliability and decarbonization must intersect. Without reliable infrastructure and the right tools and partners, commitments to efficiency and emissions reduction are at risk. Our ES stemless valve eliminates up to 100% of fugitive methane emissions, helping IOCs and NOCs meet ambitious regional net-zero and emissions targets while maintaining safe, resilient and high-performing infrastructure.

Oxford Flow is exhibiting in Hall 5 at booth 5170 at the ADIPEC Exhibition and Conference this week in Abu Dhabi, UAE.

*Offshore is a media partner of ADIPEC 2025.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.