ADIPEC 2025: AISUS exec talks offshore asset integrity and the future of robotics and AI

Key Highlights

- Remote robotic inspections can eliminate risky operations like confined space entry and use of divers.

- AISUS integrates AI-driven defect detection and predictive analytics into a cloud platform, providing actionable insights and trend analysis for better maintenance planning.

- Recent case studies demonstrate how remote tools uncovered hidden defects, enabling proactive repairs and avoiding operational disruptions.

By Ariana Hurtado, Editor-in-Chief

Ahead of ADIPEC 2025 next week, Offshore spoke with Barry Marshall, general manager at AISUS, about the evolving role of remote inspection technologies in offshore integrity management. From corrosion detection to AI-powered analytics, Marshall shares how robotic systems can reshape asset reliability, safety and sustainability across the offshore energy sector.

Offshore: Inspection technologies are evolving rapidly. What are the most pressing offshore integrity challenges AISUS is focused on solving today?

Marshall: Corrosion remains one of the biggest offshore integrity challenges, as it can quickly lead to safety, environmental and operational issues. The industry is under pressure to extend the life of existing assets while maintaining safety and reducing environmental impact, so there’s a growing need for smarter, data-driven inspection methods.

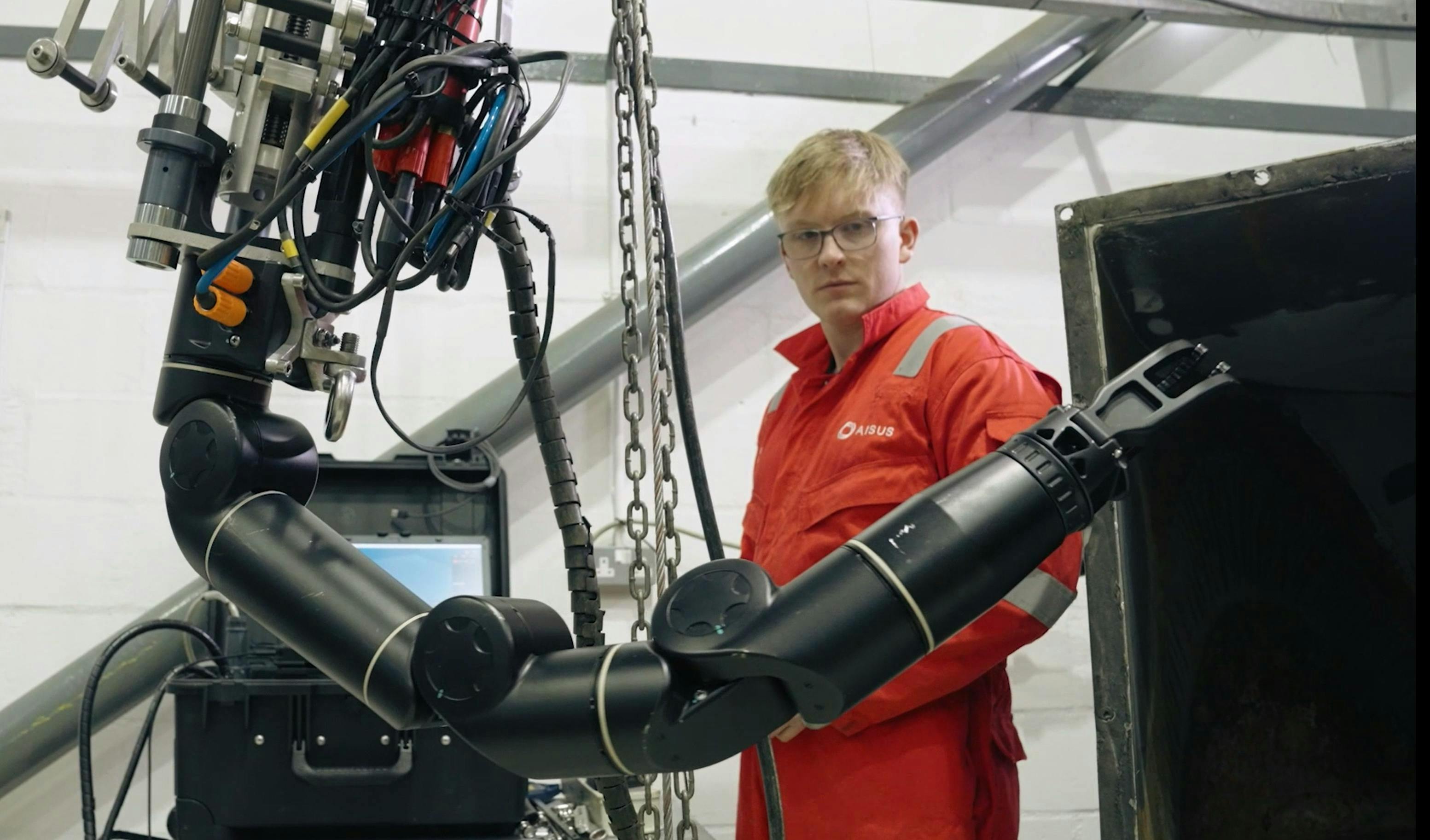

At AISUS, we’re focused on delivering technologies that remove the need for risky operations, like confined space entry, rope access and divers, while also reducing cost by eliminating expensive ROVs allowing inspections to deliver richer, more meaningful data.

In some regions, like the Middle East, inspections are still largely carried out by divers taking limited spot readings, which don’t provide a full picture of an asset’s condition. We’re helping operators transition to remote robotic inspections that offer complete coverage and more reliable insight. This supports a move away from reactive maintenance toward a proactive approach, where operators can use data trends to plan ahead, reduce downtime and make more informed integrity decisions.

Offshore: Can you share a recent offshore energy case study that revealed unexpected insights or led to operational improvements?

Marshall: With our recent expansion into the Middle East, we were pleased to work with a major operator on [an] offshore project, a full inspection of multiple seawater lift caissons. The scope included high-pressure water jetting to remove heavy marine growth, followed by remote visual inspection and ultrasonic testing from topside to the termination grille. It was a great example of how remote tools can deliver a safe, efficient alternative to traditional methods.

The inspection uncovered more than 250 wall defects and significant pitting that hadn’t been detected before due to limited previous data.

Our team was able to adjust jetting pressures on site to ensure thorough cleaning while protecting the parent material. For the client, this meant gaining a much clearer understanding of their asset’s true condition, capturing data they can now use for predictive maintenance, and completing the work without interrupting operations. With this inspection data, the operator will look to repair the defects within the caissons, as we have encouraged pre-maintenance planning.

Offshore: How is AISUS leveraging data analytics or AI to enhance inspection accuracy and reduce offshore downtime?

Marshall: Traditionally, inspection results have been delivered in static PDF reports that highlight areas of concern such as corrosion. While these reports are useful, we’re now moving beyond that by integrating AI-driven defect detection and predictive modeling into our cloud-based data platform.

This approach gives clients access to interactive, actionable data that helps them plan maintenance more strategically, reduce unnecessary downtime and extend the lifespan of their assets. Rather than just seeing what’s already happened, our software analyzes historical trends to predict where issues might develop next, providing a much fuller picture than a traditional report ever could.

Our digital platform brings everything together in one place. Operators can view 3D models, panoramic imagery and predictive analytics in an intuitive dashboard that turns inspection results into practical decision-making tools. As AI technology continues to evolve, our data team is constantly refining and expanding these capabilities to ensure clients always have the clearest, most valuable insight into their assets.

Offshore: What are the key considerations when selecting inspection tools for aging offshore energy infrastructure versus newer assets?

Marshall: When selecting inspection tools for aging offshore infrastructure, adaptability is key. Many North Sea oil platforms, for example, are approaching 50 years old and often feature limited access points and complex structures. These conditions demand tailored inspection solutions, which our design team can configure to safely and effectively navigate the challenges presented by older assets.

A common issue operators face is that as-built drawings no longer match the current platform layout. Over the years, structural modifications and additions often go undocumented, making pre-planning and access management more complex.

Additionally, aging assets typically show higher levels of degradation, meaning the parent material can be fragile. This requires careful adjustment of inspection solutions such as modifying high-pressure jetting to avoid causing further damage while removing marine growth.

Newer assets such as offshore wind farms are designed with improved accessibility and integrated data interfaces. As a result, inspection technologies can be optimized for rapid deployment, continuous monitoring and seamless data integration, helping operators maintain performance from day one.

Offshore: In terms of HSE, how are inspection technologies contributing to safer offshore energy operations, especially in high-risk environments?

Marshall: Safety is central to everything we do, and one of the biggest advantages of remote inspection is reducing how many people need to be offshore. Our magnetic crawlers and robotic systems can operate in areas that would otherwise require confined space entry, rope access or divers, meaning fewer personnel are exposed to hazardous conditions. This not only improves safety performance but also supports the overall well-being of our teams, allowing them to carry out complex work with less physical strain and time spent in challenging environments.

There’s also a wider environmental benefit. By using remote technologies, we can reduce vessel time and other resource-intensive operations [as well as] lower carbon emissions while maintaining safety and inspection quality. It’s a good example of how innovation in inspection doesn’t just protect people; it also helps operators achieve safer, cleaner and more sustainable offshore operations.

Offshore: How does AISUS approach collaboration with operators and engineers to ensure inspection solutions are fit for purpose across diverse offshore regions?

Marshall: Collaboration with operators and engineers is at the heart of how we work. From the very start of each project, we take time to understand the client’s challenges, their assets and the environments they’re operating in. By working closely with our in-house engineering and R&D teams, we can adapt and refine our inspection tools through design reviews and simulation trials to make sure they’re the right fit for each job. Whether it’s caissons, j-tubes, or other subsea or onshore structures, we believe open communication and teamwork are key. This custom-solution approach helps us deliver inspection data that’s accurate, meaningful and genuinely useful for the operator’s integrity goals.

Offshore: How do you see remote inspection and robotics reshaping offshore asset management in the next three to five years?

Marshall: We’re seeing a real shift from reactive inspections to predictive integrity management. Instead of waiting for failures, operators are embedding robotics and digital insights into proactive maintenance strategies. The focus is increasingly on safety [and] removing personnel from confined spaces or hazardous areas. And robotics are playing a key role in achieving that, by designing and engineering custom robotic solutions tailored to each client’s needs, including systems with manipulator arms capable of accessing spaces where traditional ROVs can’t reach. This flexibility represents where remote inspection is heading toward fully integrated, adaptable systems that minimize risk and maximize efficiency.

AI and machine learning are also transforming offshore asset management. By combining real-time data with predictive analytics, operators can make faster, more informed decisions that improve long-term reliability.

As regulations tighten and regulatory environmental expectations grow, there’s also greater emphasis on sustainable operations. AISUS has been carbon neutral since 2020, and we continue to develop technologies that not only enhance safety and performance but also support the industry’s drive toward lower environmental impact [and] more sustainable operations.

AISUS will be exhibiting in Hall 8 (UK Pavilion) at booth 8450 from Nov. 3-6 at the ADIPEC conference and exhibition in Abu Dhabi.

Offshore is a media partner of ADIPEC.

About the Author

Ariana Hurtado

Editor-in-Chief

With more than a decade of copy editing, project management and journalism experience, Ariana Hurtado is a seasoned managing editor born and raised in the energy capital of the world—Houston, Texas. She currently serves as editor-in-chief of Offshore, overseeing the editorial team, its content and the brand's growth from a digital perspective.

Utilizing her editorial expertise, she manages digital media for the Offshore team. She also helps create and oversee new special industry reports and revolutionizes existing supplements, while also contributing content to Offshore's magazine, newsletters and website as a copy editor and writer.

Prior to her current role, she served as Offshore's editor and director of special reports from April 2022 to December 2024. Before joining Offshore, she served as senior managing editor of publications with Hart Energy. Prior to her nearly nine years with Hart, she worked on the copy desk as a news editor at the Houston Chronicle.

She graduated magna cum laude with a bachelor's degree in journalism from the University of Houston.