Antelope adds centralizer subs to product line

Offshore staff

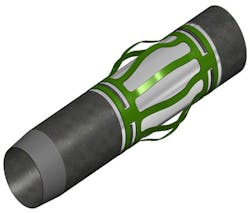

HOUSTON – Antelope Oil Tool has developed the CentraMax RT1 (rotating), PI1 (push-in) and PT1 (pull-through) centralizer subs.

The sub series is designed to run in tight tolerance deepwater well applications and ultra-narrow annular clearances (usually when the annular clearance is smaller than ¾ in. or less than the material stack).

Using CentraMax CT one-piece centralizers, Antelope directly installs the centralizers onto the threaded sub body. The RT1 centralizer sub is pulled and/or reciprocated both in and out of the restriction through the use of an internal machined integral sub body anchor, allowing the centralizer to rotate freely inside the hole. The company says the design prevents the machined sub body internal anchor from getting underneath the bows and the end collars, allowing the bows to fully compress, while adding safety and performance to the tool.

The PI1 centralizer sub allows the centralizer to be pushed and reciprocated in both directions when installed between two integral machined sub body anchors. The design is equipped with specially designed bows and is able to rotate freely.

The PT1 centralizer sub is pulled and/or reciprocated both in and out of the restriction with specially designed “window” openings in the centralizer’s end collars.

The sub body installation reduces the centralizer’s material stack, which allows the centralizer to safely and effectively pass through the narrow I.D. restrictions. These centralizers are produced from a single-piece, heat-treated steel which minimizes potential weld and component failures.

President and CEO Bill Kelley said: “We want to give our customers every product choice possible for theirdeepwater well applications. Engineering close tolerance centralizer subs was a natural progression for Antelope.”

04/13/2016

Share your news withOffshoreat [email protected]