Techniques with adjustable gauge tools yield more directional control options

Choices and alternatives always give a buyer a sense of satisfaction, knowing they are getting the most for their dollar. This also applies to the oil and gas industry. Having only one alternative for a particular well application doesn't develop much of a comfort zone around a given technology. Growth of a comfort zone in a high-cost, high-tech business takes time and plenty of comparative studies.

Current alternatives for drilling in long lateral sections are conventional rotary drilling, conventional steerable motors, newer rotary steerable technologies, and creative combinations of all three.

In hole angles above 85°, directional corrections are predominantly made to hole inclination, not the azimuth. Conventional steerable assemblies have limitations and exhibit adverse effects on the wellbore due to induced doglegs (increase in torque and drag) and poor hole cleaning (no rotation while sliding). An adjustable stabilizer used as a near bit/below motor stabilizer can yield predictable inclination control in a rotary drilling mode.

The ability to adjust downhole stabilizer gauge size has been available for over a decade. Used most often as a string stabilizer, applications have ranged from drill string friction reduction, to aggressive directional control while rotary drilling. The most common application in the early years of use was changing a bottom hole assembly's build/drop tendency, without a trip out of the hole to change bottom hole assembly (BHA) components.

Enhanced directional control

Successful rotary drilling applications depend on the length of the pony collar between the near-bit and adjustable stabilizer. More aggressive build rates will be achieved by placing the adjustable stabilizer closer to the near-bit stabilizer, putting more upward bend in the BHA and effectively "kicking" the bit upward.

The pony collar length from the adjustable stabilizer to the first string stabilizer will influence the directional response of an assembly using an adjustable stabilizer in a near-bit position. The gauge of the first stabilizer will dictate the drilling tendency of the assembly, a build/ drop, hold/drop, or drop/more drop.

Generally, adjustable gauge tools are run above the motor in as close proximity to the bit as possible. Placement varies from directly on top of the motor, to a position above a short pony or standard drill collar, depending on the degree of aggressiveness in the directional plan, and if potential for building angle during the bit run is required.

Adjustable stabilizers are placed above motors to primarily control the wellbore inclination through the tangent sections of a well. The adjustable stabilizer is used to minimize the sliding necessary for inclination correction and to keep the string rotating as much as possible. In S-type wells, the tool is used through the tangent section, then cycled to maximum gauge, and aids the normal dropping tendency of the BHA.

An adjustable gauge stabilizer placed above a "short" motor, in soft formation where the inclination has a tendency to drop, requires an extra 5-10 ft of pony collar to provide extra "belly" in the BHA. This aids the building capabilities of the BHA.

Andergauge, one of the leaders in adjustable gauge tools, has more than 150 well examples running adjustable gauge stabilizers below a conventional motor assembly. Lateral wells in the Austin Chalk are the most common application.

Long, horizontal sections needing slight vertical adjustment are normal for directional plans in this geologic formation. Austin Chalk runs tend to be approximately 1,500-1,700 ft in length. The normal practice is to drill with a conventional steerable assembly until sliding becomes impossible, then pick up a rotary assembly with adjustable gauge stabilizer, and drill to total depth.

Although a good alternative for maintaining well trajectory in lateral sections, sections which require more aggressive vertical correction, or slight lateral turn, may need another alternative. Also, extending the distance from bit to the bearing assembly on the motor with the addition of an adjustable gauge tool increases the moment-arm for lateral forces acting on the bearing assembly and drive shaft of the motor. Aggressive directional corrections can cause motor problems such as bearing and drive shaft fatigue and failure. This situation has fostered another drilling tool alternative for horizontal and extended reach drilling applications - integrating an adjustable gauge device on a conventional mud motor.

Integration with mud motor

Like the adjustable string stabilizer mentioned above, Sperry Sun's adjustable gauge motor (AGM) was designed as a tangential inclination maintenance control tool. Drilling longer extended reach sections in the Austin Chalk formation requires higher rotating bit speed than a rotary drilling assembly can offer. Placement of an adjustable gauge device on a mud motor gives higher bit speed and more directional control capability.

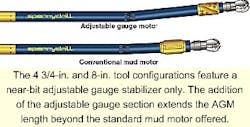

To enhance the directional capabilities of a 0.75-1.00° bend AGM, the adjustable gauge section of the AGM is placed in a near-bit position. This near-bit positioning varies from immediately above the bit box to just above the power section of the motor. Two different configurations are being evaluated to decide which one is most preferred by directional drillers and operators.

The 4 3/4-in. and 8-in. tools contain a near-bit adjustable gauge stabilizer only. The 6 3/4-in. tool incorporates an integral blade near-bit stabilizer, at-bit-inclination (ABI) sub, and adjustable gauge stabilizer (AGS) above the power section of the motor.

Directional aggressiveness of this integrated adjustable gauge concept is represented by the ability of the AGM to obtain turns of 3° over a course length of 100 ft. As another example, an international operator needs to drill 20,000 ft horizontal sections at approximately 8,000 ft true vertical depth (TVD), and in carbonate geology. The well-behaved nature of a wellbore in this type of formation, and the enhanced drilling capabilities of this concept, makes this extended reach, horizontal well a reasonable objective.

Numerous alternatives are available for finite directional control in extended reach wells. Creative combination and integration of available technologies will extend even further horizontal drilling techniques.;

Acknowledgement

R. Dinnie of Andergauge Drilling Systems and P. Roberts of Sperry Sun Drilling Services contributed to this article.