New internal baffle design dampens wave motion on floating platforms

By Dr. Ted Frankiewicz, Vice President, Natco Liquid Process Solutions

A new computer simulation helped design an oil and gas separator smaller than previous models by up to 50%. The smaller size reduces the overall weight and footprint of the offshore processing platform. Such a reduction can save millions in construction and operating costs.

Separating oil, water, and gas is particularly difficult on floating platforms because wave motion tends to mix the three phases. Natco previously relied on costly physical testing to evaluate separator designs. This did not allow the visualization of the liquid phase movement inside the vessel. Using computational fluid dynamics (CFD) software to study the hydrodynamics inside a separator, engineers can see what happens to the oil, water, and gas during even the most complicated wave motions.

For example, engineers learned that a horizontal baffle configuration, often used in separators, was ineffective, and that conventional porous baffles had too much porosity to dampen the liquid motion. The new internal baffle design dampens wave motion so well that it reduces separation time sharply. Since it takes less time for oil and gas to separate, the vessel can be smaller.

Wave effects

A large percentage of oil production separation is now done on floating platforms, such as semisubmersibles, tension leg platforms, and floating, prod-uction, storage, and offloading vessels. Separating the oil and water from gas is done in a stand-alone three-phase separator that occupies part of the production platform. Oil companies like to make floating platforms as small as possible to minimize the initial construction cost and on-going operating expenses. Reducing the weight of the platform by just one pound, for example, is estimated to save $5-$8 in construction costs. To accommodate customers, manufacturers of separators strive to shrink the size of their systems. This has been difficult, however, because of the wave motion experienced by floating platforms. The platform can experience wave motion in six degrees: surge, sway, heave, pitch, roll, and yaw. These have a natural mixing effect on the oil, water, and gas, increasing the time it takes to separate the oil and gas.

The optimal combination

Oil and gas separators employ an arrangement of internal baffles to dampen wave motion. The more effective the baffles are, the more they suppress sloshing. Baffles can be placed in different orientations and at different locations within the separator. They can be made of different materials, and the amount of porosity can vary widely. Finding the optimal combination of these variables is a critical design goal. In the past, engineers built scale models to determine how well certain baffle designs performed. The testing was expensive, and infor-mation obtained from testing was limited because the tests were done on scale models. It wasn't known how accurately the results could be applied to a full size vessel. In addition, even with models made of Plexiglas, it was difficult to visualize and interpret the sloshing or the mixing patterns.

Scale model testing

The search for an alternative to scale-model testing led to CFD. This software can simulate the full-size vessel and show the details of liquid motion. The simulation provides fluid velocity and pressure values throughout the solution domain for time-dependent problems with complex geometries and boundary conditions. As part of the analysis, a designer may change the geometry of the system or the boundary conditions, such as the inlet fluid velocity, and view the effect on fluid flow patterns. This is an efficient and effective tool for generating detailed parametric studies, significantly reducing the amount of experimentation necessary to develop a device.

Fluent CFD software from Fluent Inc. in New Hampshire, was chosen for this particular application because it can solve capable of solving multiphase flow problems, a requirement for this application since it deals with oil, water, and gas flow.

Previous baffle designs

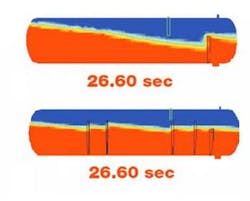

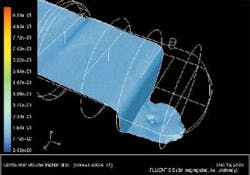

The first experience in applying the software to separator design was to model an existing separator in the analysis software. The geometry was created directly from its preprocessor, Gambit. This module also automatically produced the geometry meshing. Dr. Chang-Ming Lee, the engineer who performs the analyses, took advantage of the software's ability to produce both unstructured and structured meshes. He placed an unstructured mesh of tetrahedral and hybrid elements at both ends of the separator, scaling the unstructured mesh to account for differences in the sizes of the components being analyzed. In the central portion of the device, a mesh of hexahedral elements was placed. Both fine and coarse meshes were used. The fine mesh had about 126,000 cells while the coarse mesh had approximately 40,000. To represent the wave motion of the processing platform, a user-defined function with assistance from technical support based on known environmental data was created. Lee used a volume of fluid (VOF) model to track the free-surface interface and liquid-liquid interface in the vessel and used the k-epsilon model for turbulence.

Findings

The first separator analyzed had no internal baffles. An animated presentation of the results made it easy to see the severe sloshing inside the vessel. Next, Lee modeled the separator with baffles, which were specified as porous media, in the vertical orientation. With this design he tried different baffle materials, shapes, and degrees of porosity. He ran multiple CFD analyses to find the most effective combination of the design variables. One of the interesting findings in this set of analyses was that conventional porous baffles had too much open area to provide sufficient damping. Using CFD gave the ability to evaluate varying amounts of open area to obtain more effective damping. To assess the different designs, a comparison of the amplitudes as related to the fluctuating drag coefficient on the end wall of the unit derived from the sloshing motion was implemented. A preliminary design with less open area had a drag coefficient that was 56% of the original value. Modifications to the design gave a reduction to about 38% of the original value.

Optimized baffle design

This method was used to design a three-phase separator that completes oil, water, and gas separation in three to four minutes of retention time, using half the volume of previous devices. The design uses the new, optimized baffle design and placement that was developed based upon the earlier analyses. CFD analysis allowed engineers to find the best location for baffles within the particular separator. The specifications about where that separator would be located on the platform also were put into the simulation model. Those results, combined with more effective baffles, created a more effective separator. Because separation time was significantly reduced, the separator size could be reduced as well. The analyses that were run to optimize baffle placement were specific to that one separator's location on the platform. But now that the model exists, it is possible to optimize baffle placement in any new offshore separators.