MRI measurement includes analysis of reservoir fluids

A new real-time enhanced reservoir fluids analysis product is being used with present tool technology to generate magnetic resonance imaging (MRI) measurements with interpreted analysis. The tool, developed by Halliburton Energy Services, is known as the MRIL PrimeTime Log (MRIL is for magnetic resonance imaging log).

The information obtained is presented in real time as the tool is being run, and it generates direct MRI measurements with interpreted analysis, typically define net/gross sand ft, pore-size distributions, total porosity, effective porosity, clay porosity, net permeability ft, permeability, net hydrocarbon ft of each reservoir, and gas and oil saturations in the flushed zone. Statistical quality assurance indicators allow for insight to the degree of certainty in the information provided to the end user.

Jody Powers of Halliburton said the log results in real-time reservoir solutions and reservoir-description reports, plus MRI measurement technology to bring about greater efficiencies in rig-time utilization and enhanced well productivity.

Unlike other magnetic resonance technologies, the tool takes direct measurements and provides reservoir formation evaluation analysis in real-time at the field. Using analysis methods similar to those used in the medical industry for patient diagnosis, results are immediately made available through the tool's ability to incorporate multiple measurement wait times and inter-echo spacing measurements into a single well-log pass. Additionally, it measures several key factors that influence the ability of a well to produce commercial quantities of oil or gas accurately.

CT drilling tower skiddable, flexible

A skiddable-coiled tubing drilling (CTD) tower for Phillips Petroleum Company Norway can accommodate a larger equipment range on a wide variety of platforms. The unit was designed by BJ Well Services (Europe, Africa Division) and built in Stavanger. - Coil tubing tower HLF11.

Although skiddable, the towers have been designed primarily to operate on virtually any platform, can handle extraordinarily large equipment, and are capable of performing limited pipe-handling of jointed tubulars. The tower can also be used in standard well servicing work. The designers contend the tower provides a safer and more flexible approach to coiled tubing drilling.

The tower is freestanding and self-supporting, with operations performed at considerable height, but in a safe working environment. Even while drilling when fully overbalanced, having a lubricator long enough to accommodate the drilling tools offers a high degree of operational maneuverability and improved well control.

The new design incorporates two separate skidding systems: one for the main structure and one for the injector. The injector can also be turned on a swivel plate up to 60 degrees in either direction. As a result, multiple skidding functions permit the tower to be rigged-up wherever convenient. When used with the swivel system for the reel, it is possible to set equipment down once and perform service work on multiple wells. This eliminates costly rig-up and rig-down procedures, the risk of injury that may be associated with these procedures, and frees cranes for other tasks on the platform.

Limited pipe-handling of jointed tubulars is made possible through the incorporation of a winch and traveling tong system. This system can also be used for stack, riser rig-up, and tool deployment, thus reducing the need for cranes. Initial set-up of the total system is safe, simple and quick, even with large landing and locking pins in each module. The internal stair system allows for safe, easy access to each level as the tower is stacked up.

Testing of this tower began earlier this year on a contract that required a package of CT drilling and well services in the Ekofisk Region off Norway. To ensure safe and effective operation, the testing of the tower was performed on an Ekofisk platform where the firm had a contract for two wells. The technology is being considered for use in the Eldfisk and Tor fields.

The tower features remotely operated Norsok V16 pump units, a pressurized A 60-rated control cabin, two HR 5100 injectors, a sound-proofed 5,000 psi operating pressure power pack, and a 75-ton capacity swivel base for the reel.

Multiple open-hole tubing expansion world first

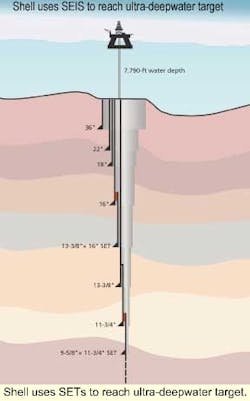

Shell Exploration & Production Company (SEPCo) has installed a second solid expandable tubular (SET) system in an ultra-deepwater well in Alaminos Canyon 557. The R&B Falcon Deepwater Nautilus semisubmersible drilling rig was used to install multiple openhole SET installations, a world first. Enventure Global Technology and Shell Technology Ventures installed the 1,521-ft-long, 9 5/8-in. open-hole expandable liner system inside 11 3/4 in. casing, further increasing overall length-of-hole with negligible reduction in casing diameter, thus enabling Shell to explore the deeper objectives of the ultra-deepwater well.

The first SET system was run in September 2000 - a 1,186-ft, 13-3/8 in. by 16 in. open-hole expandable liner system expanded into 16 in. base-casing. The second SET installation, a 9 5/8 in. by 11 3/4 in. expandable liner system, is the first expandable open-hole system of its size installed, as well as the world's deepest SET installation (measured depth of more than 16,000 ft).

The 1,521-ft system was expanded in approximately five hours, using propagation pressures of 2,000 psi. The expandable liner system was pressure-tested at 1,500 psi for 30 minutes with no leaks, fulfilling operator and regulatory requirements. Post-expansion internal diameter of the 9 5/8 in. expandable liner was 9.978 in. (compared to a pre-expansion diameter of 8.921 in.), while post expansion yield and collapse are estimated at 4,430 psi and 1,270 psi, respectively (based on prior surface tests). The 9 5/8-in., 36.0 lbs/ft liner, expanded 11.8% into 11 3/4 in. base-casing and open-hole, exhibited a 4% reduction in overall length.

The 9 5/8 in. by 11 3/4 in. system is the 19th commercial solid expandable tubular installation - six open-hole liner systems and 13 cased-hole systems. To date, Enventure has expanded a total of 16,116 tubular ft and 528 connections.